Mechanical arm grasping device and method for fruit automatic packaging device

An automatic packaging and grabbing device technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as skin bruises, achieve the effects of improving automation, good market promotion prospects, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

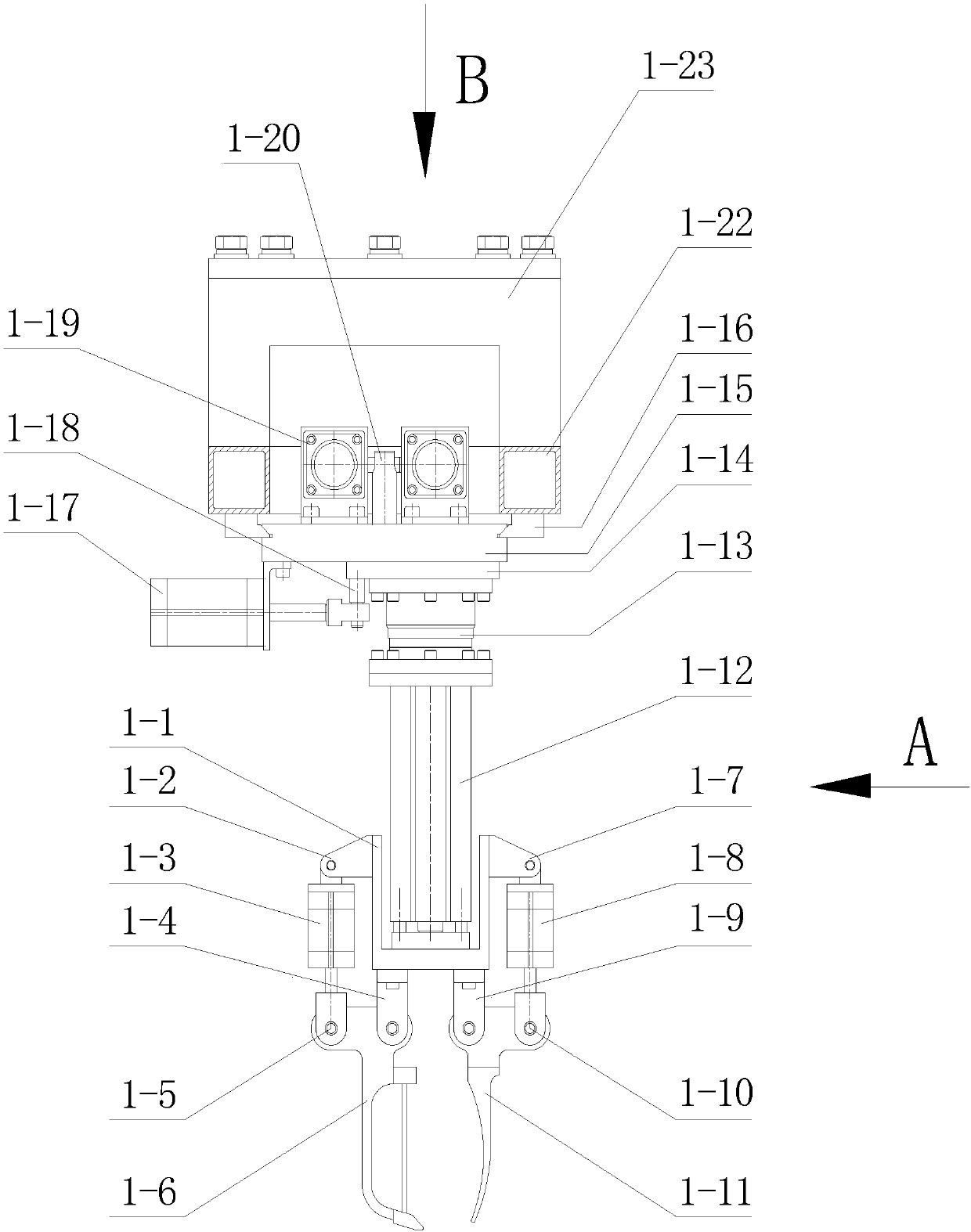

[0056] This embodiment is a mechanical hand grasping device and method, which is applied to fruit automatic packaging equipment. The mechanical hand grasping device is provided with five sets of grasping robots, which can grasp five fruits at a time. This embodiment takes kiwi fruit packaging as an example , The specific structure and working principle of the manipulator grabbing device are as follows:

[0057] 1. The overall structure of the manipulator grabbing device:

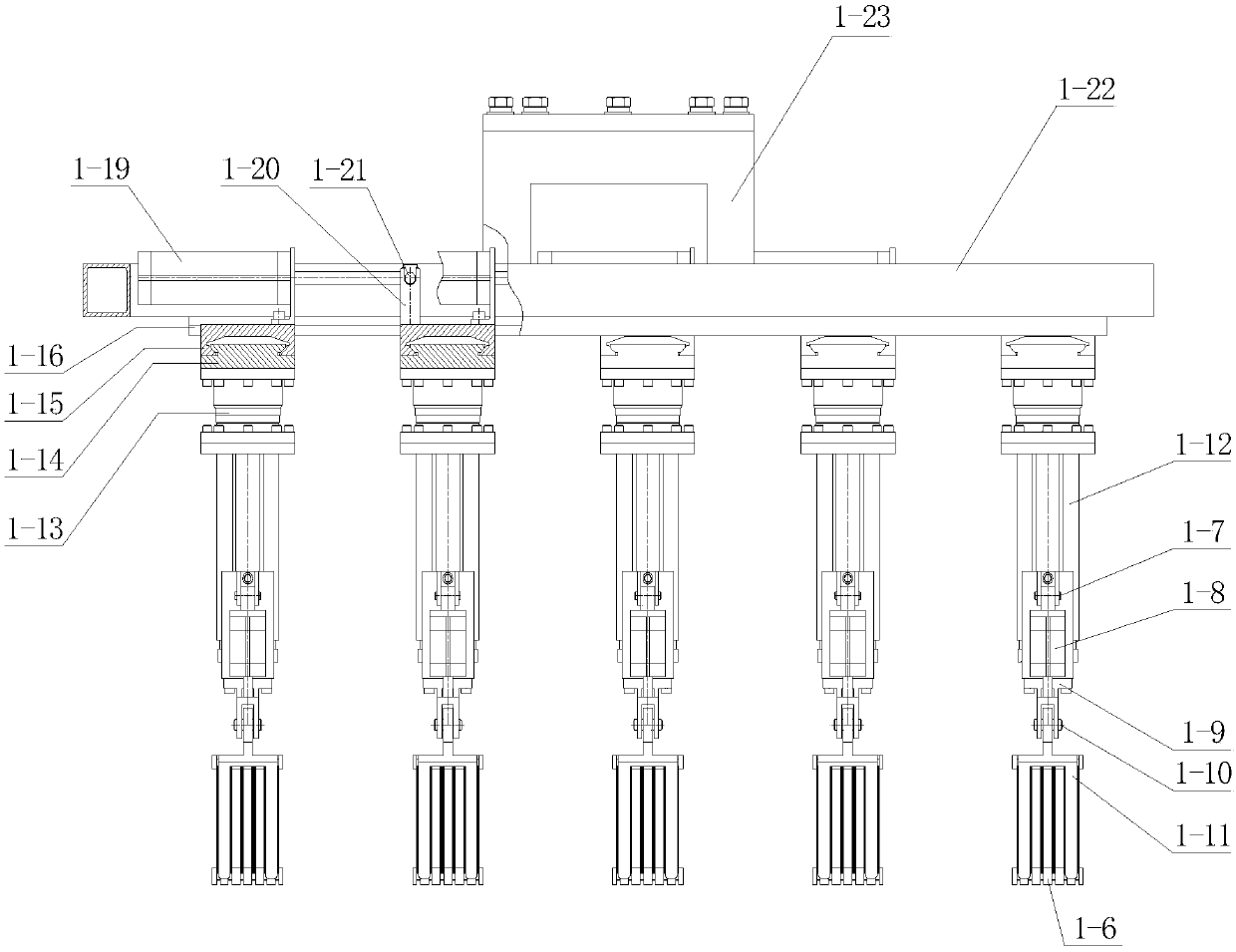

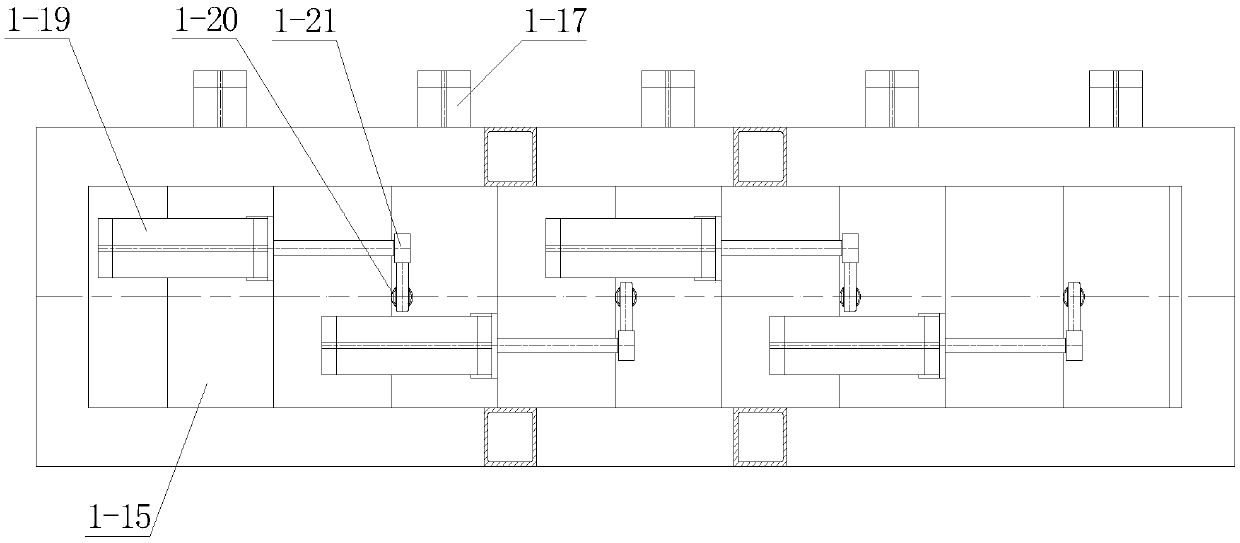

[0058] Such as Figure 1-3 Shown is the overall structure of the robot gripping device. The whole device is composed of five sets of grasping robots (the structure of each set of grasping robots is as follows: Figure 4 As shown), five fruits can be picked at the same time.

[0059] Such as figure 2 As shown, five sets of grabbing manipulators with the same structure are assembled on the mounting base 1-22, vertically downward and parallel to each other. The mounting base 1-22 is a frame structure, and the uppe...

Embodiment 2

[0105] Compared with Embodiment 1, the robot grasping device and method of this embodiment is different in that: only one set of grasping robot is provided in the mechanical grasping device, and only one fruit is grasped at a time.

[0106] The manipulator grasping device includes a mounting base, a grasping manipulator, a lifting cylinder and a harmonic reducer. The harmonic reducer is installed under the mounting base, the top of the lifting cylinder is connected to the bottom of the harmonic reducer, and the bottom of the lifting cylinder is connected to the grasping manipulator ; The lifting cylinder drives the grabbing manipulator to move up and down, and the harmonic reducer drives the grabbing manipulator to rotate. Among them, the mounting seat is used as the main body base of the entire manipulator grasping device, the top of which is externally connected with the robot arm, and the bottom of which is used to install the components that constitute the manipulator grasping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com