Multi-groove limiting V belt

A technology of body and guide plate, which is applied in the field of multi-groove limit V-belts, which can solve the problems of V-belt detachment from the contact surface and low working efficiency of V-belts, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

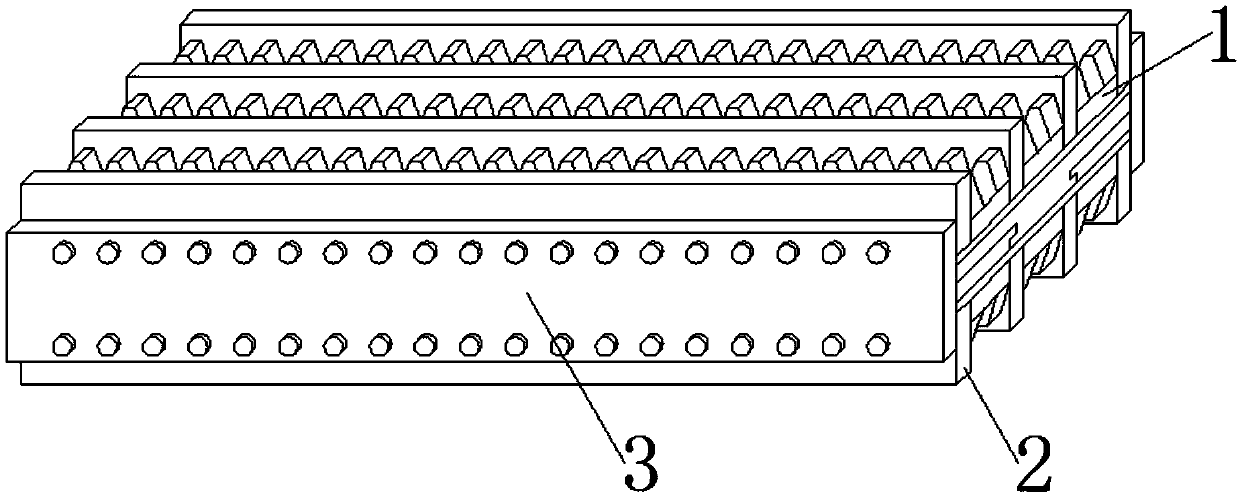

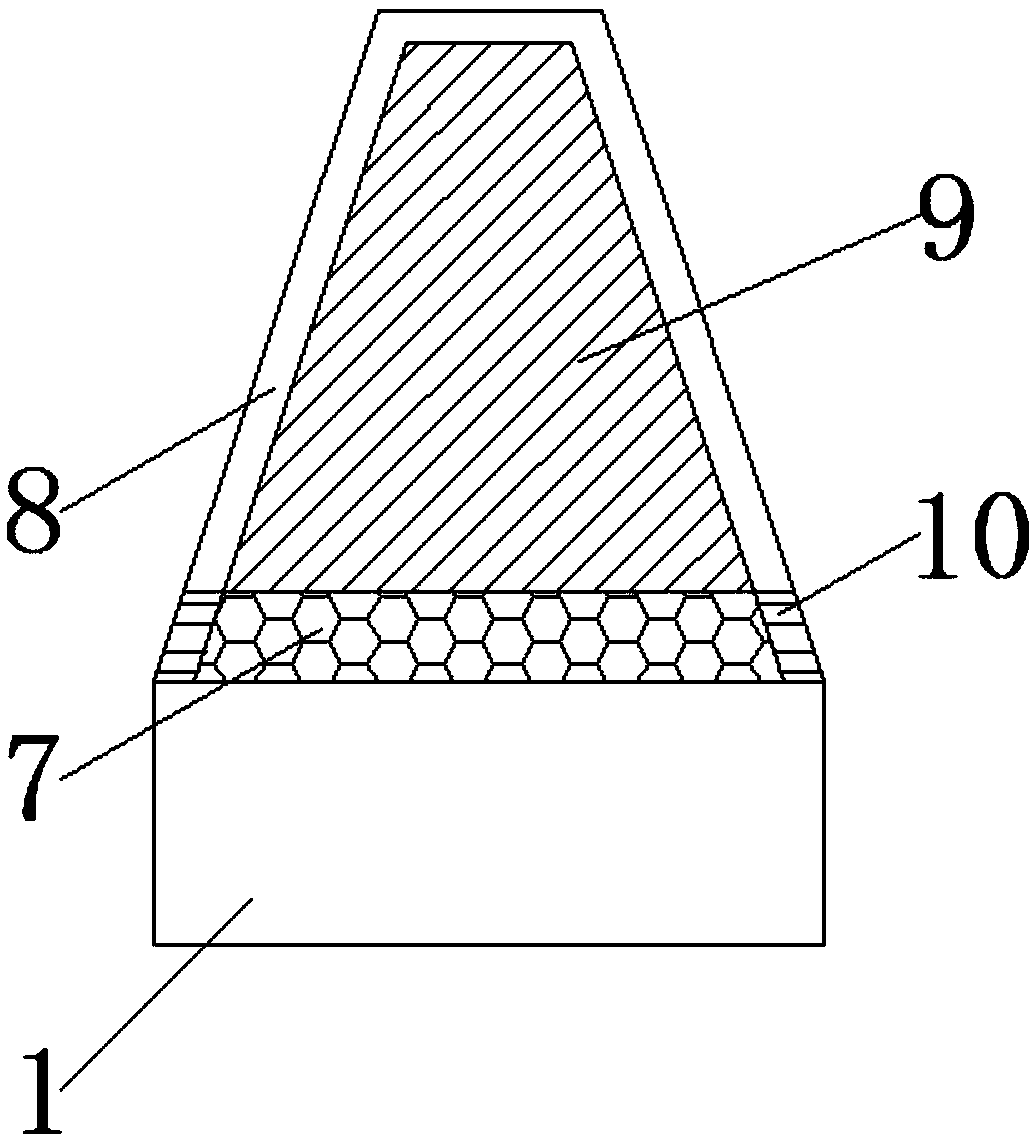

[0022] refer to Figure 1-2 , a multi-groove limit V-belt, three V-belt bodies 1 are provided, a V-belt body 1 is arranged between two guide plates 2, the guide plate 2 is flush with the bottom of the V-belt body 1, and the upper part of the guide plate 2 The end surface is higher than the tooth end surface of the V-belt body 1; the bottom of the V-belt body 1 and the guide plate 2 are fixedly connected with a reinforcement structure; the height of the guide plate 2 is 1.5 times the height of the V-belt body 1, and the width range of the V-belt body 1 Between 2.1-3.8cm.

[0023] Through the above technical solution, when the device is working, multiple V-belt bodies 1 can drive multiple engaging mechanisms, so that one active can drive multiple driven ones, which improves the working efficiency of the device during work, and The guide plate 2 not only assists the transmission of the V-belt body 1, but also prevents the V-belt body 1 from disengaging from the meshing mechanism...

Embodiment 2

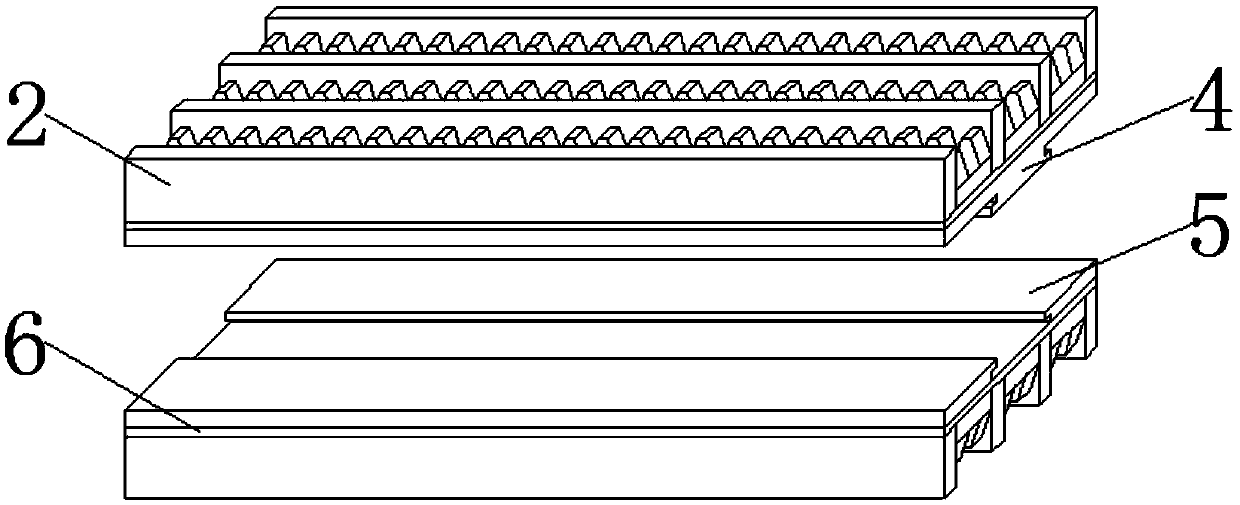

[0025] refer to figure 2 , a multi-groove limiting V-belt, which is basically the same as in Example 1, furthermore, the thickness of the reinforcement structure is 1.2-1.9cm, the reinforcement structure is preferably a plastic reinforcement plate 6, and the V-belt can be increased by the plastic reinforcement plate 6 The stability between the body 1 and the reinforcing plate 6 improves the working stability of the device.

Embodiment 3

[0027] refer to figure 2 , a multi-groove limit V-belt, which is basically the same as Embodiment 1, furthermore, the end of the plastic reinforcement plate 6 away from the V-belt body 1 is fixedly connected with the first butt plate 4 or the second butt plate 5, the first The butt plate 4 is matched with the second butt plate 5, and the first butt plate 4 and the second butt plate 5 are fixed together so that the two devices can be fixed together for use, so that the combined device can be driven through the top and also through the bottom. End drive improves the working efficiency of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com