Encircled single-beam operation crane carriage and application method

A technology of lifting trolley and single beam, which is applied in the direction of load block, transportation and packaging, and load hanging components, etc., which can solve the problems of lifting height limitation, limitation, and inconvenient operation, so as to reduce vertical occupation space and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

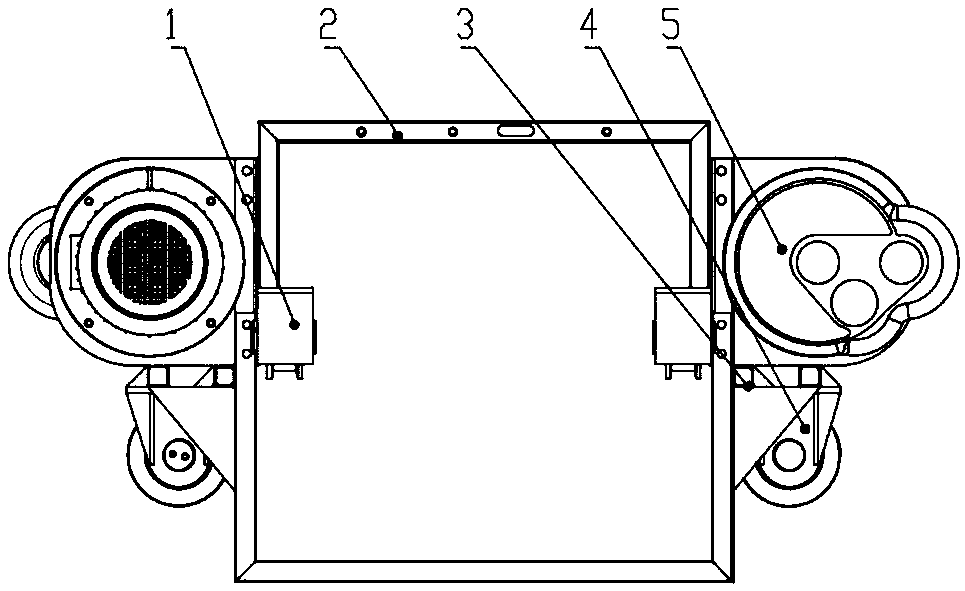

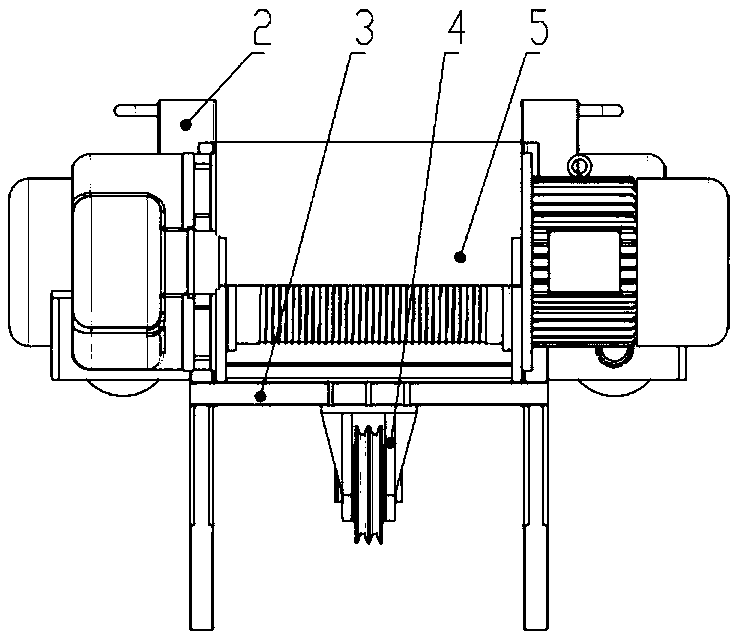

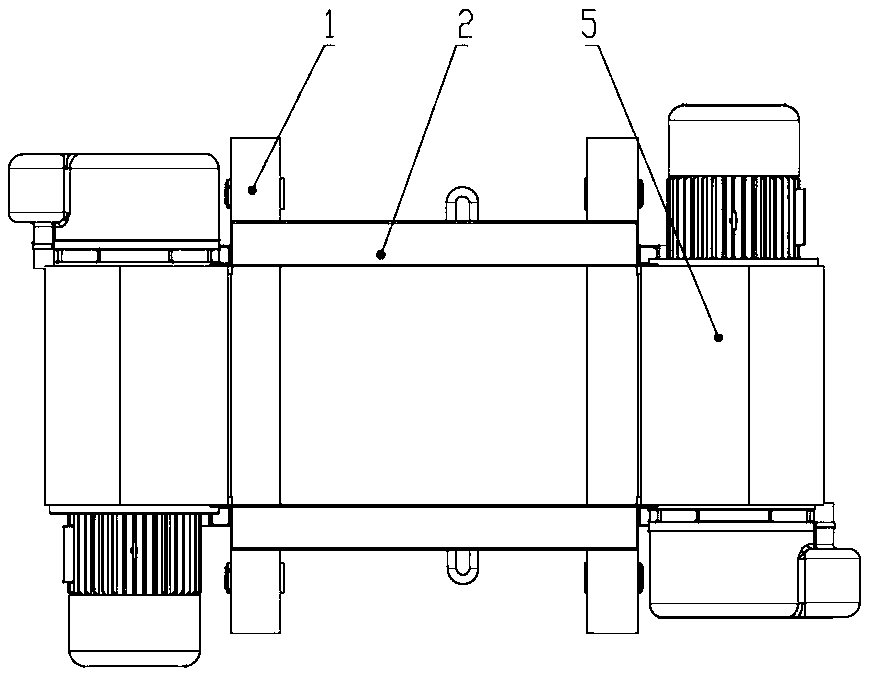

[0021] Example 1: Structural composition of an encircling single-girder crane trolley

[0022] In order to achieve the above purpose, the present invention mainly changes the structural form of the trolley fundamentally, changing from the original top-mounted or suspended type to a side-mounted type, placing the lifting hoist of the trolley on the side, and installing the running track of the trolley on the side of the single beam , carrying the lifting trolley, the whole structure of the lifting trolley is similar to a frame structure "hugging" on a single beam. The lifting trolley is mainly composed of the traveling beam 1 of the lifting trolley, the connecting structure frame 2, the pulley installation platform 3, the fixed pulley block 4, and the electric hoist 5. The traveling beam 1 of the lifting trolley is a box-shaped structure welded by steel plates, and the bottom is hollowed out. The running steel wheels are installed at the corresponding positions near the front ...

Embodiment 2

[0023] Embodiment 2 A method of using an encircling single-girder operating lifting trolley

[0024] 1. According to the cross-sectional size of the single beam and the installation position of the running track, determine the size of the connecting structure frame 2, assemble the lifting trolley and install it on the single beam, and can move back and forth along the running track under the traction of the driving force.

[0025] 2. Connect the control system and the power cord to make the electric hoist 5 in a workable state.

[0026] 3. The operation control system makes the hoisting trolley run above the hoisting object, the operation control system drops the hoisting wire rope, connects the wire rope and the hoisting object, and after confirming that it is firm, lifts the wire rope to lift the object, and moves the crane equipment to send the hoisting object to the designated place.

[0027] 4. Operate the control system to lower and land the hoisting object, and fine-tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com