High-polymer gravel water-permeable composite pile and construction method thereof

A technology of high polymer and gravel piles, which is applied in the direction of sheet pile walls, foundation structure engineering, soil protection, etc., can solve the problems of low bearing capacity of single piles and easy bulge damage on the upper part of the pile, and achieve short construction period , Relieve the dependence on the bearing capacity of the restraint effect, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

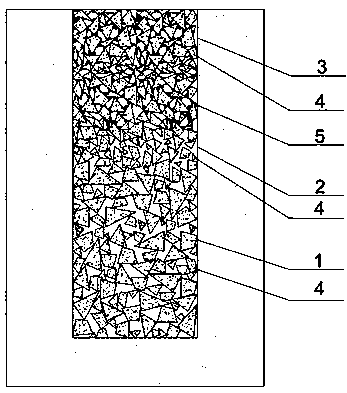

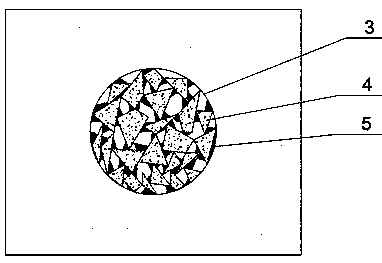

[0020] Such as figure 1 and 2 As shown, a high polymer gravel permeable composite pile includes a bottom gravel pile 1, a transition section gravel pile 2 and a high polymer gravel pile 3 poured sequentially from bottom to top.

[0021] The high polymer crushed stone pile 3 is a rigid pile formed by cementing the crushed stone particles 4 through the high molecular polymer 5 , and the high polymer crushed stone retaining wall retains some gaps between the crushed stone particles 4 . The height of the polymer gravel pile 3 is not less than 4 times the diameter of the high polymer gravel permeable composite pile, and the height is not less than 2m. The mixing ratio of high molecular polymer 5 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap