Process for producing double helical glass tube, light-emitting tube for fluorescent lamp, and fluorescent lamp

A manufacturing method and technology of glass tubes, which are applied in glass manufacturing equipment, discharge tube/lamp manufacturing, glass molding, etc., can solve problems such as easy breakage of convex parts, achieve improved mechanical strength, low breakage incidence, and avoid operation The effect of an increase in the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

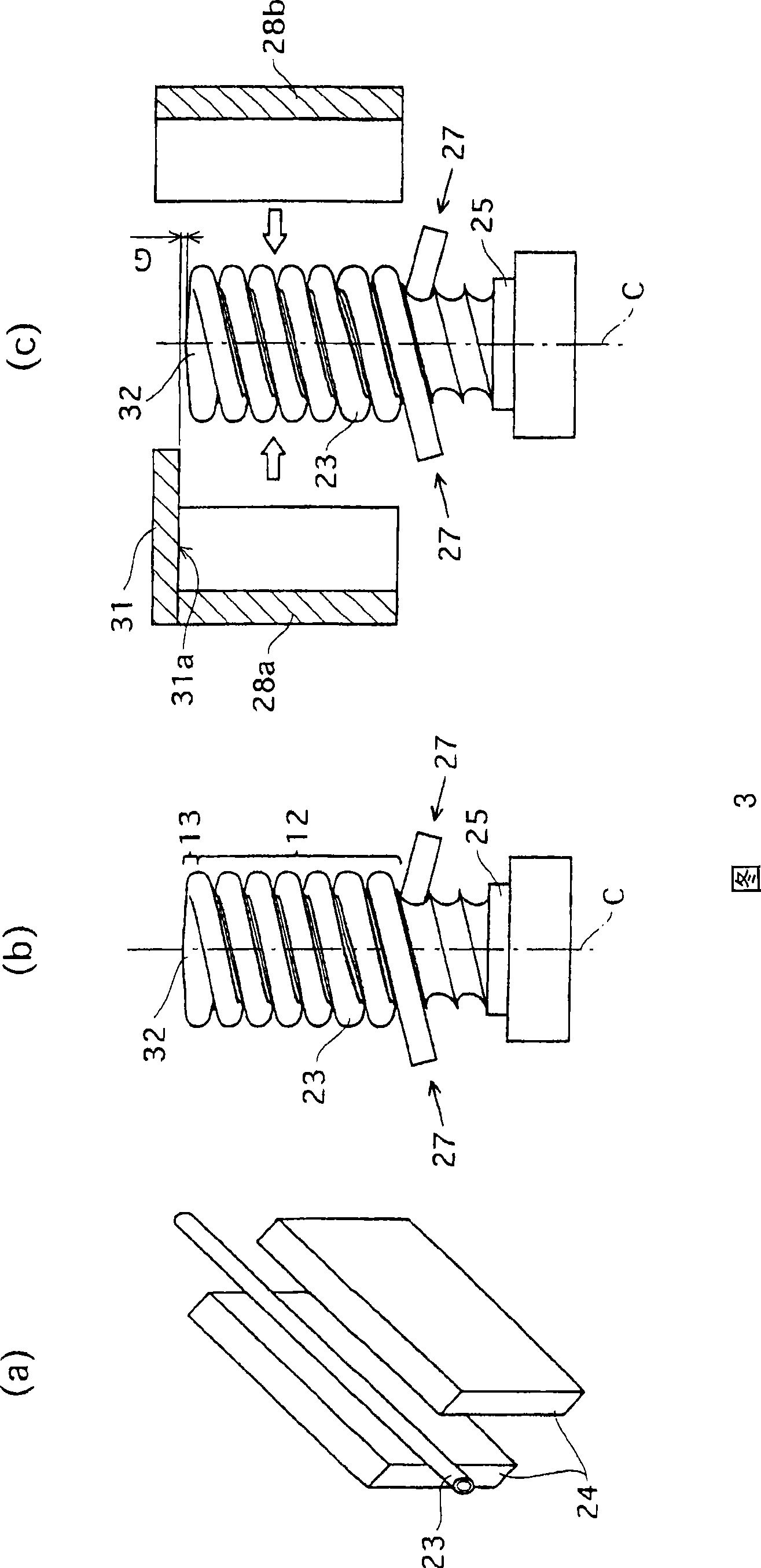

[0054] The best mode for carrying out the present invention will be described in detail with reference to the accompanying drawings.

[0055]

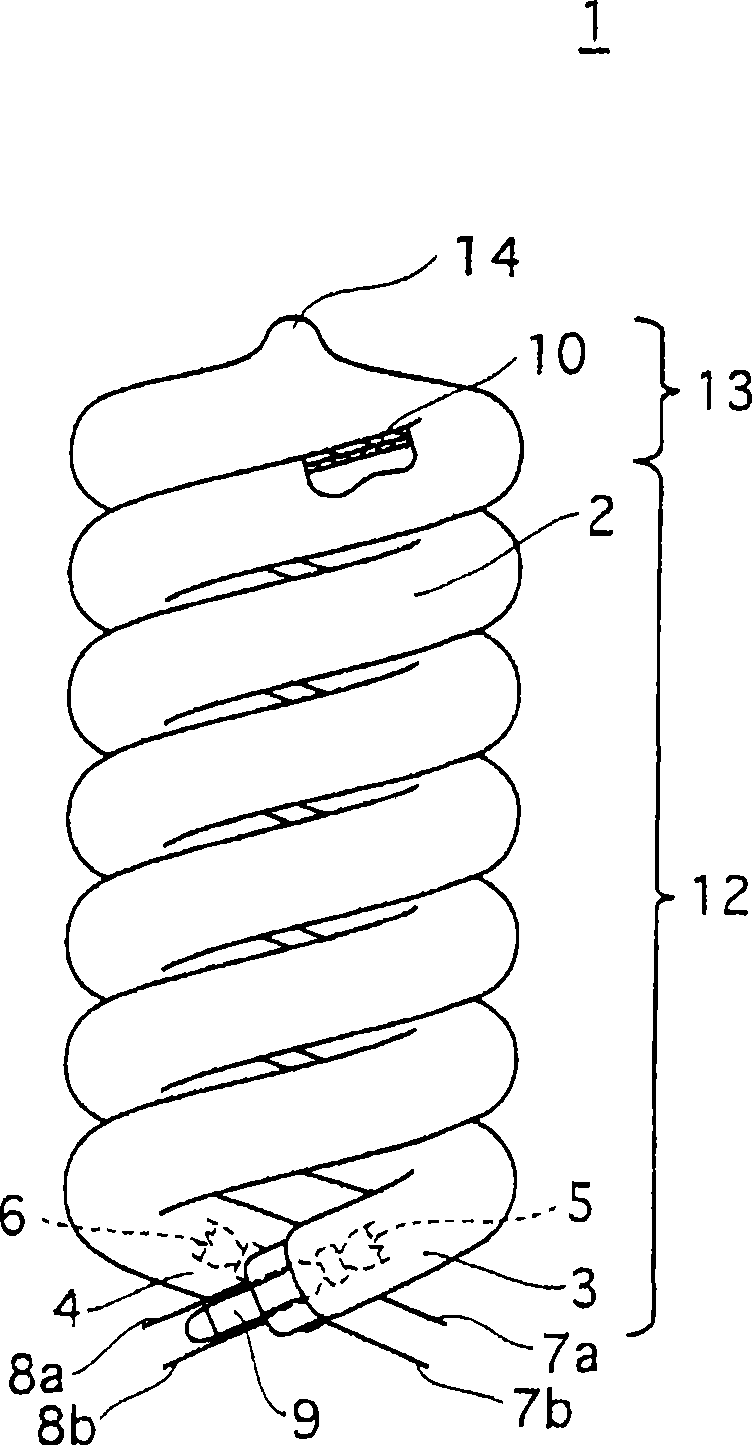

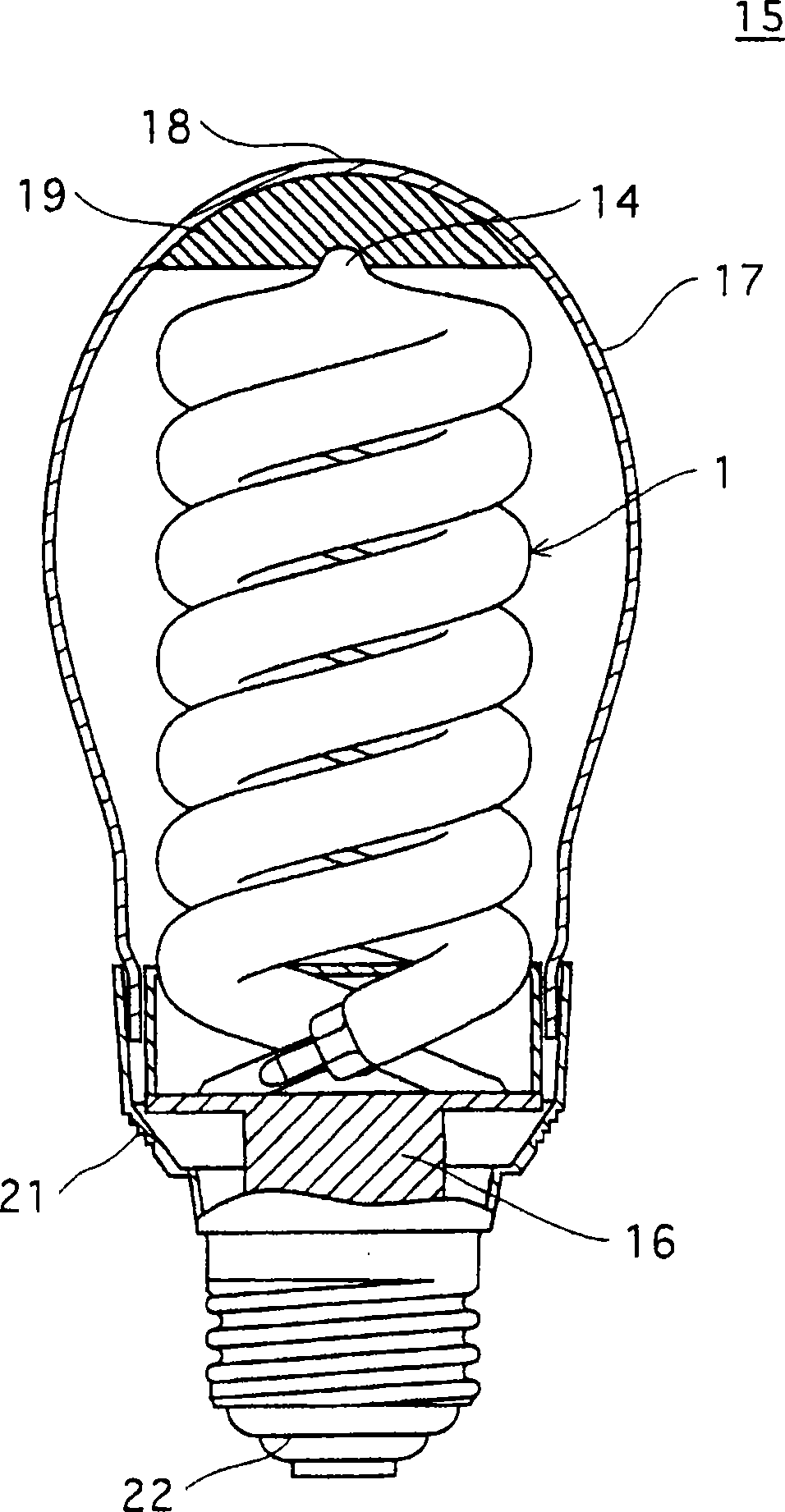

[0056] figure 1 and figure 2 The typical light-emitting tubes and the overall structure of the lamp are respectively shown in the 22W bulb-type fluorescent lamp variety that replaces the 100W general bulb according to the embodiment of the present invention.

[0057] The luminous tube 1 is formed by using a double helical glass tube 2 as a container, and airtightly sealing a pair of wires 7a-7b, 8a-8b at the ends 3, 4 of the tube. The pair of wires 7a-7b, 8a -8b holds the tungsten wire electrodes 5 and 6 respectively through glass bead installation. At the pipe end 3, an exhaust pipe 9 is also packaged (the end portion is closed after the luminous tube is exhausted).

[0058] The main inner surface of the glass tube 2 is coated with a rare earth phosphor 10, and in addition to about 5 mg of mercury, 400 Pa of argon is enclosed as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap