Anti-clogging gauze window with humidifying function

An anti-clogging and functional technology, applied in the field of screen windows, can solve the problems of unsmooth air, blocked screen windows, inconvenient daily use, etc., and achieve the effect of improving the purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

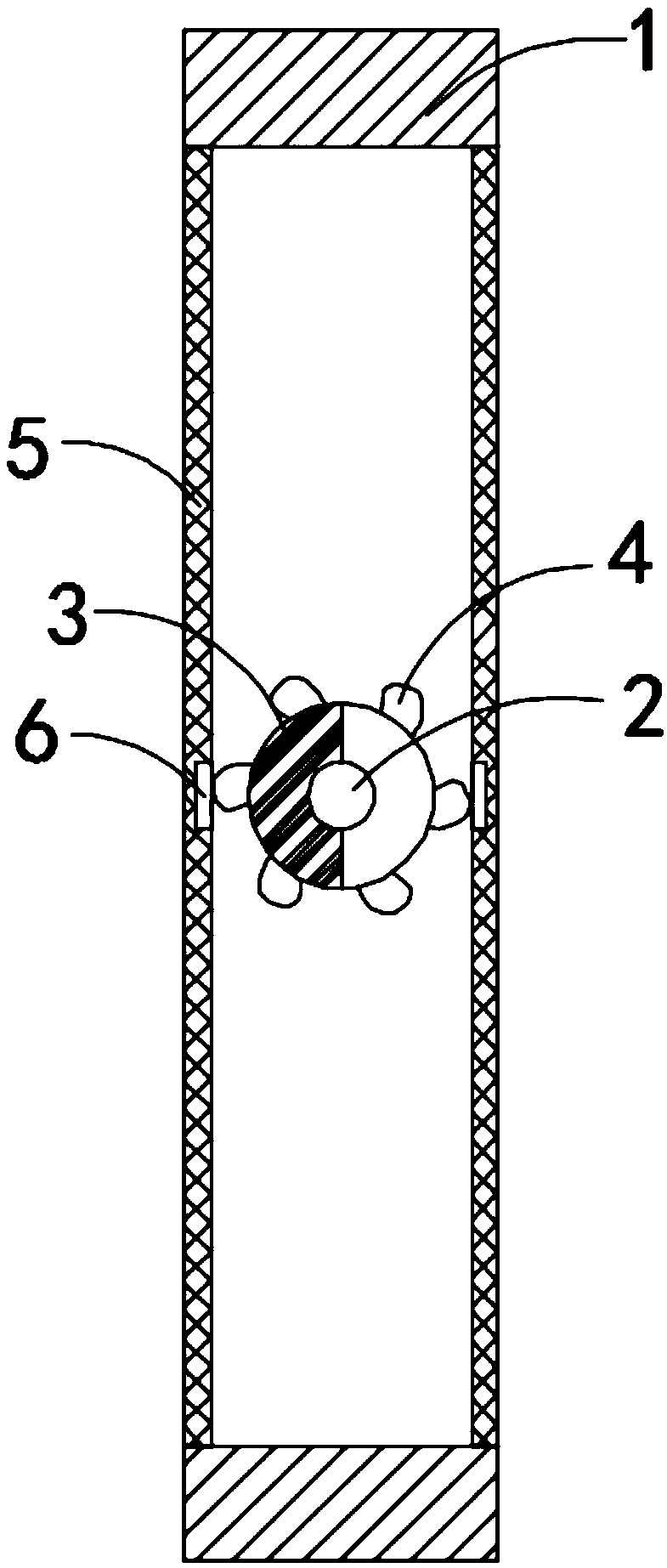

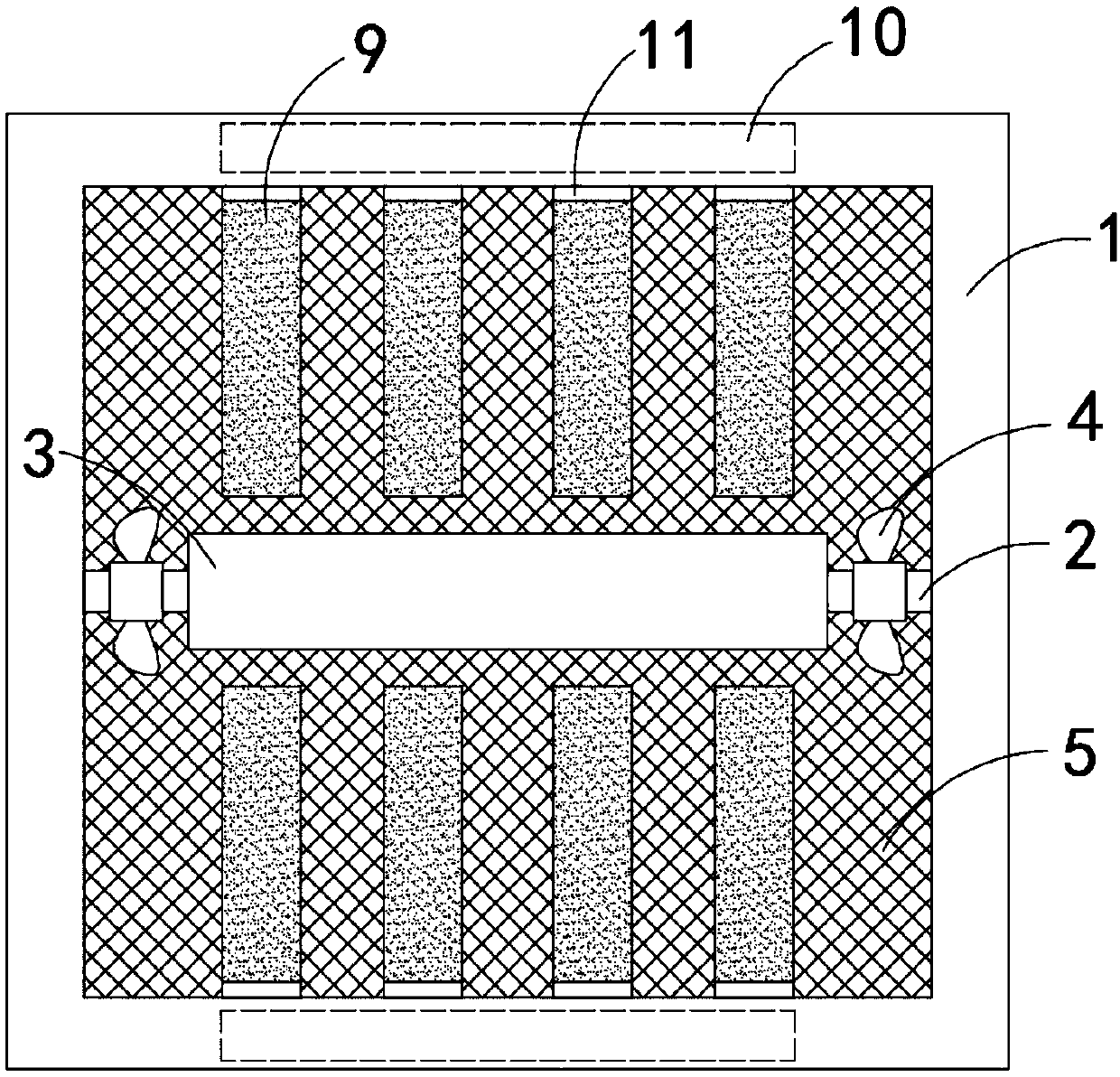

[0019] Such as figure 1 As shown, an anti-clogging screen window with humidification function includes a window frame 1, the inner rotation of the window frame 1 is connected with a horizontally arranged rotating shaft 2, and both ends of the rotating shaft 2 are rotationally connected with the middle part of the window frame 1 through rotating bearings. The rotating shaft 2 is coaxially fixedly connected with a permanent magnet cylinder 3 and two wind-driven wheels 4, and the two wind-driven wheels 4 are located on the left and right sides of the permanent magnet cylinder 3 respectively. 5 is woven with stainless steel wire, the gauze 5 is fixedly connected to the inner side wall of the window frame 1, and the opposite side walls of the two gauzes 5 are fixedly connected with a permanent magnetic strip 6, and the permanent magnetic strip 6 is connected to the permanent magnetic cylinder 3 The positions correspond to each other, the magnetic poles on the opposite sides of the ...

Embodiment 2

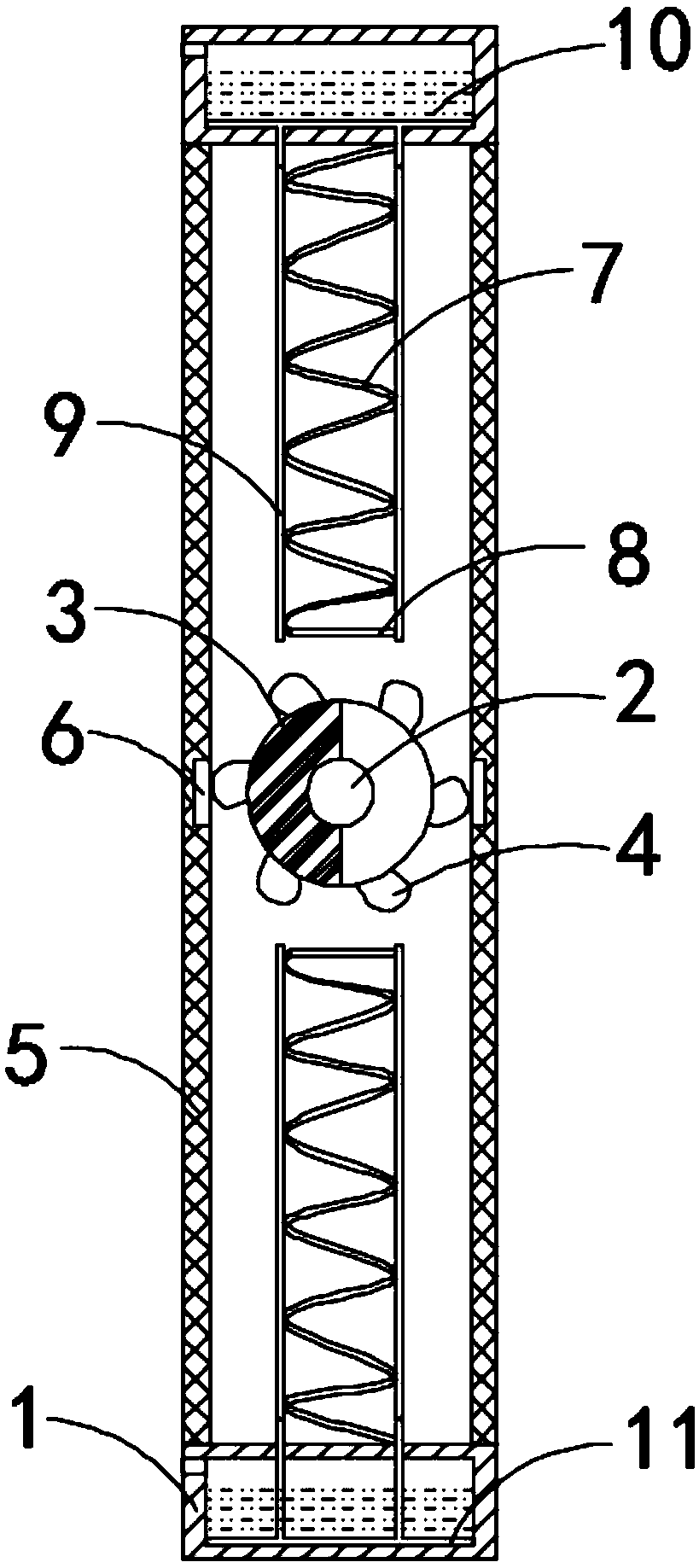

[0022] Such as Figure 2-3 As shown, the difference between this embodiment and Embodiment 1 is that the humidifying mechanism includes a plurality of springs 7 fixedly connected to the side wall of the window frame 1, and one end of the springs 7 close to the permanent magnet cylinder 3 is fixedly connected with a permanent magnet piece 8 It should be noted that the magnetic poles of the permanent magnet piece 8 on the upper side of the rotating shaft 2 and the opposite side of the permanent magnet piece 8 on the lower side of the rotating shaft 2 are the same, and under the action of the permanent magnet cylinder 3, the two springs 7 are always in the opposite direction. state, that is, when one of the springs is in an extended state, the other is in a shortened state, and the spring 7 is fixedly sleeved with a water-absorbing net 9, which can be woven with elastic water-absorbing fibers, and the inside of the window frame 1 A water storage chamber 10 is provided. It should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com