Method for treating rock section in pipe jacking construction

A treatment method and technology in construction, which can be applied to earthwork drilling, mining equipment, tunnels, etc., and can solve problems such as increasing construction costs, failure of pipe jacking machines, and encountering rocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

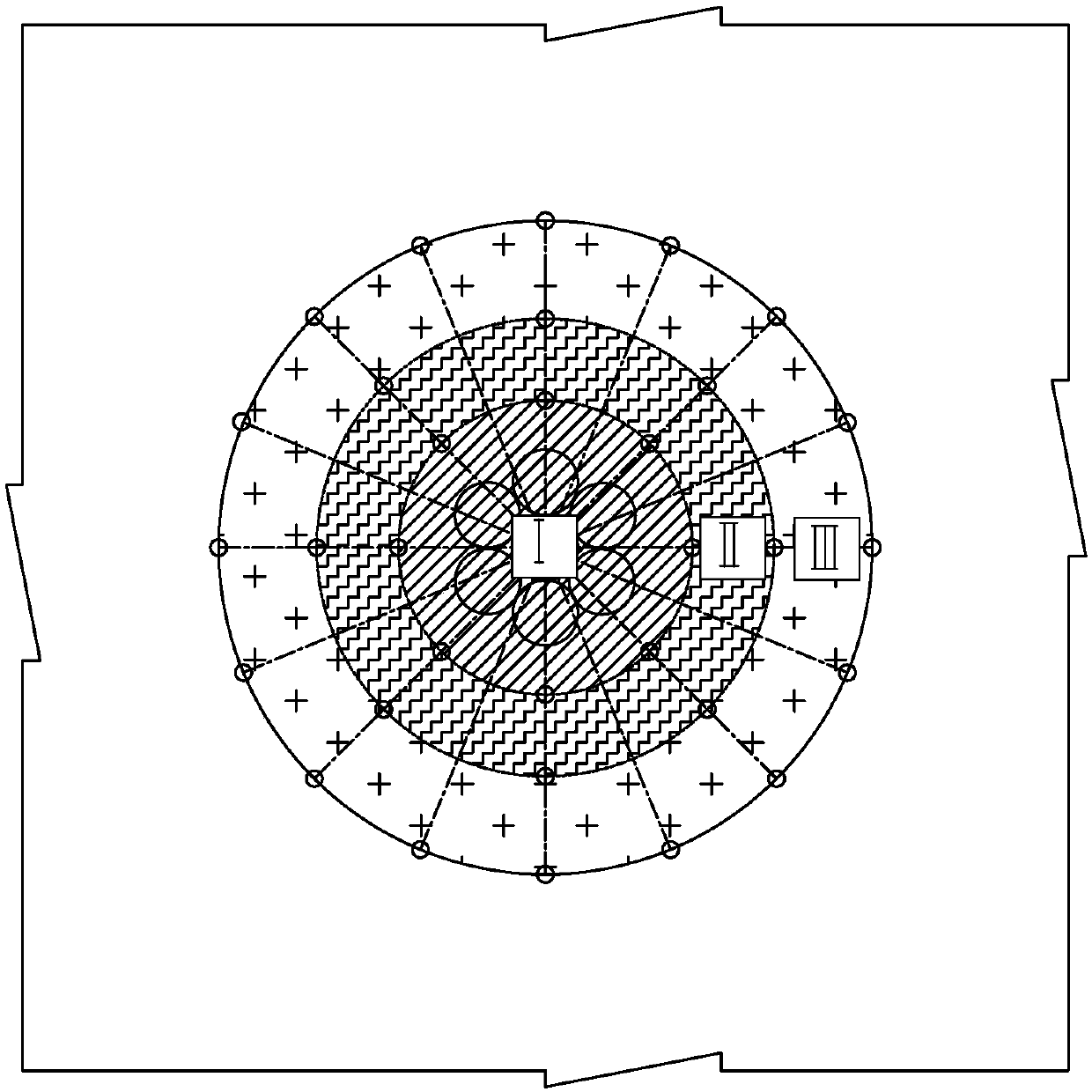

[0017] Refer to attached picture. According to the processing construction method of the rock section in the pipe jacking construction of the present invention, when the pipe jacking construction is constructed to the rock section along the design path, the following steps are included:

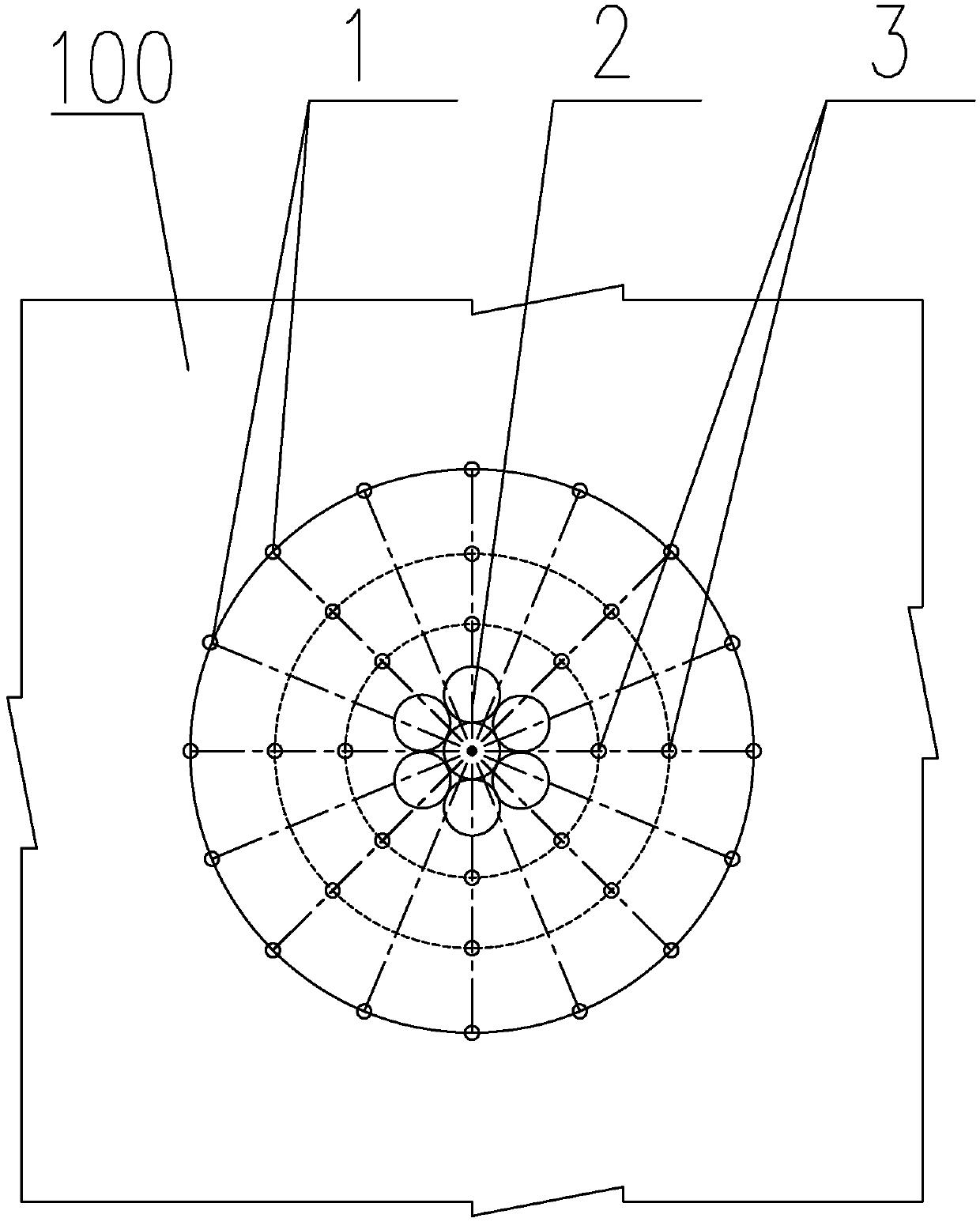

[0018] (1). Drill peripheral holes: use manual air drill to press figure 1 As shown, peripheral holes 1 are drilled at intervals of about 30 to 50 cm along the pipeline design contour line, so that the excavated part and the reserved part 100 become independent blocks bounded by the peripheral holes 1 to ensure the structural section.

[0019] (2). Drilling hollow holes: use a hand-held core drill to press figure 1 As shown, a hollow hole 2 is drilled at a suitable position in the middle of the excavation surface. The hollow hole 2 is synthesized by drilling holes of a plurality of hand-held core drills. The diameter of the drill hole of the hand-held core drill is Φ150mm. The depth is 1.50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com