Supporting component and detection equipment

A technology for supporting parts and supporting parts, which is applied in measuring devices, mechanical measuring devices, mechanical solid deformation measurement and other directions, and can solve the problems affecting the accuracy of glass substrate sag detection and glass substrate positioning deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features, and their specific implementation methods, structures, features, and Efficacy, as detailed below.

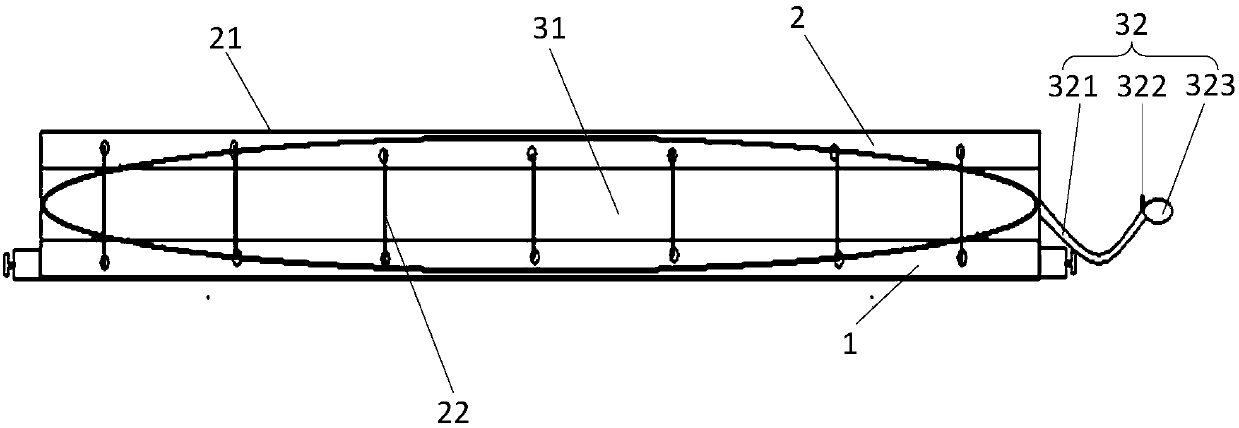

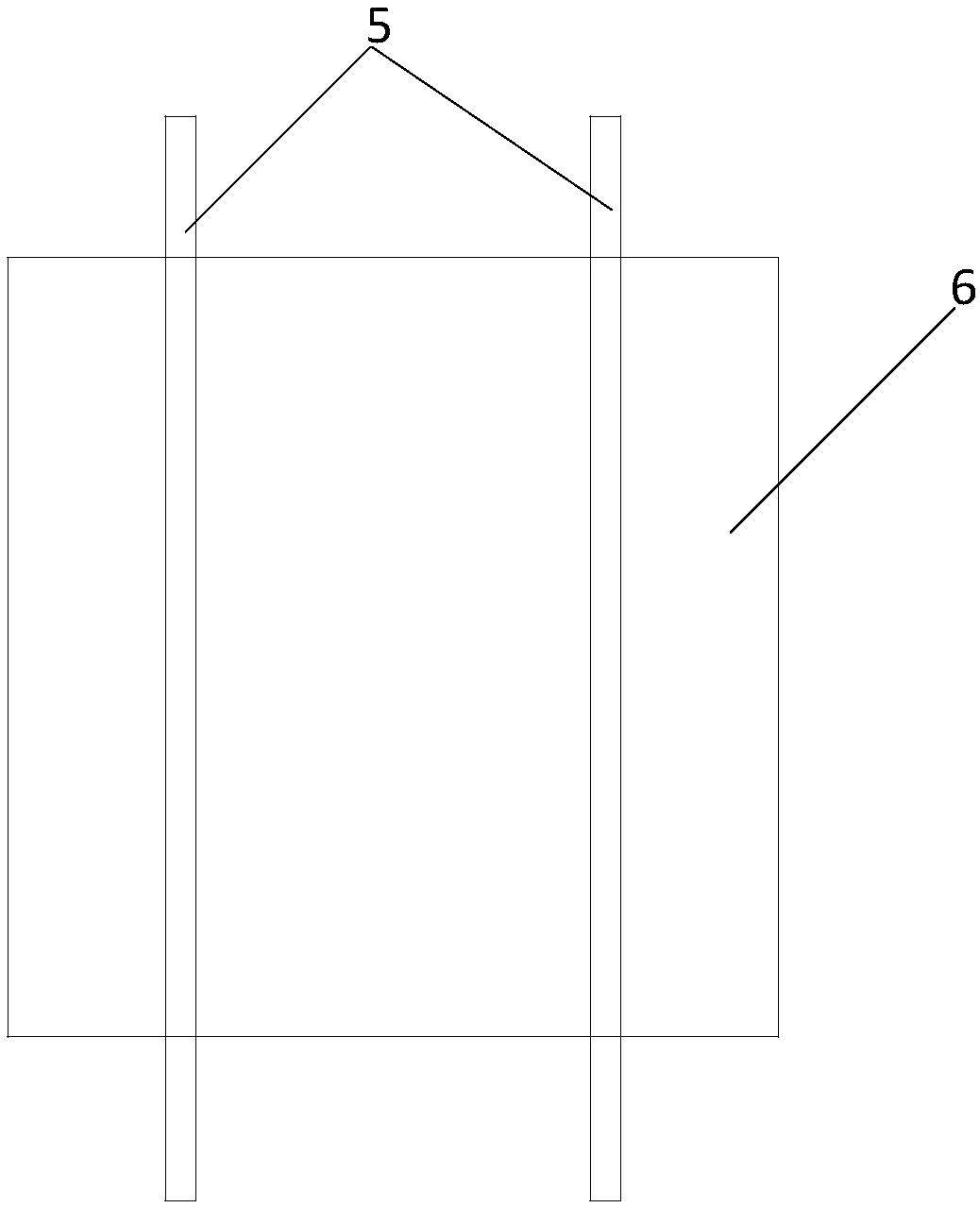

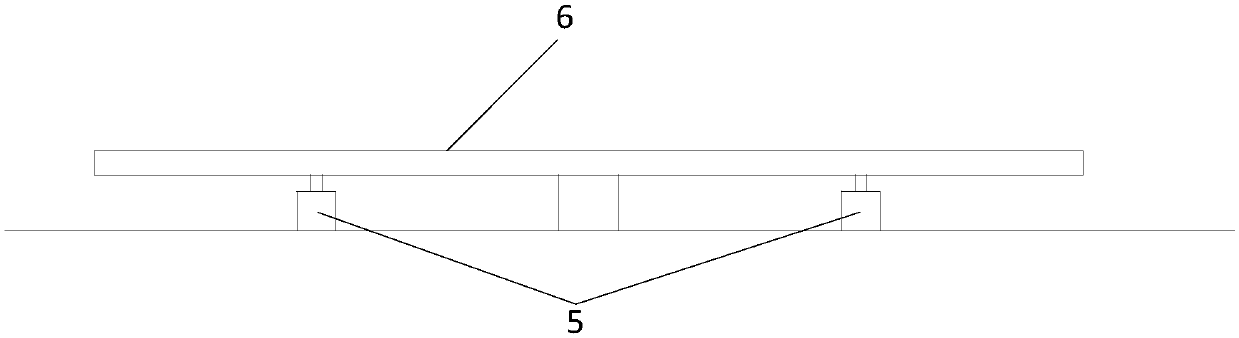

[0027] Such as figure 1 , figure 2 , image 3 As shown, the present disclosure provides a supporting member including:

[0028] The base 1, the support portion 2 and the lifting mechanism, wherein the lifting mechanism includes a telescopic airbag 31 and an inflation and deflation assembly 32, the bottom of the telescopic airbag 31 is connected to the base 1, and the top of the telescopic airbag 31 is connected to The supporting portion 2 and the inflation and deflation assembly 32 are connected to the telescopic airbag 31 for inflating or deflating the telescopic airbag 31 to adjust the support height of the support portion 2.

[0029] Among them, the above-mentioned two supporting parts are ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com