Turbine control device prognostics

A control device and turbine technology, applied in the direction of fuel valve of turbine/propulsion device, fuel control of turbine/propulsion device, safety device, etc., can solve problems such as unsafe operation, valve leakage, unplanned operation interruption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

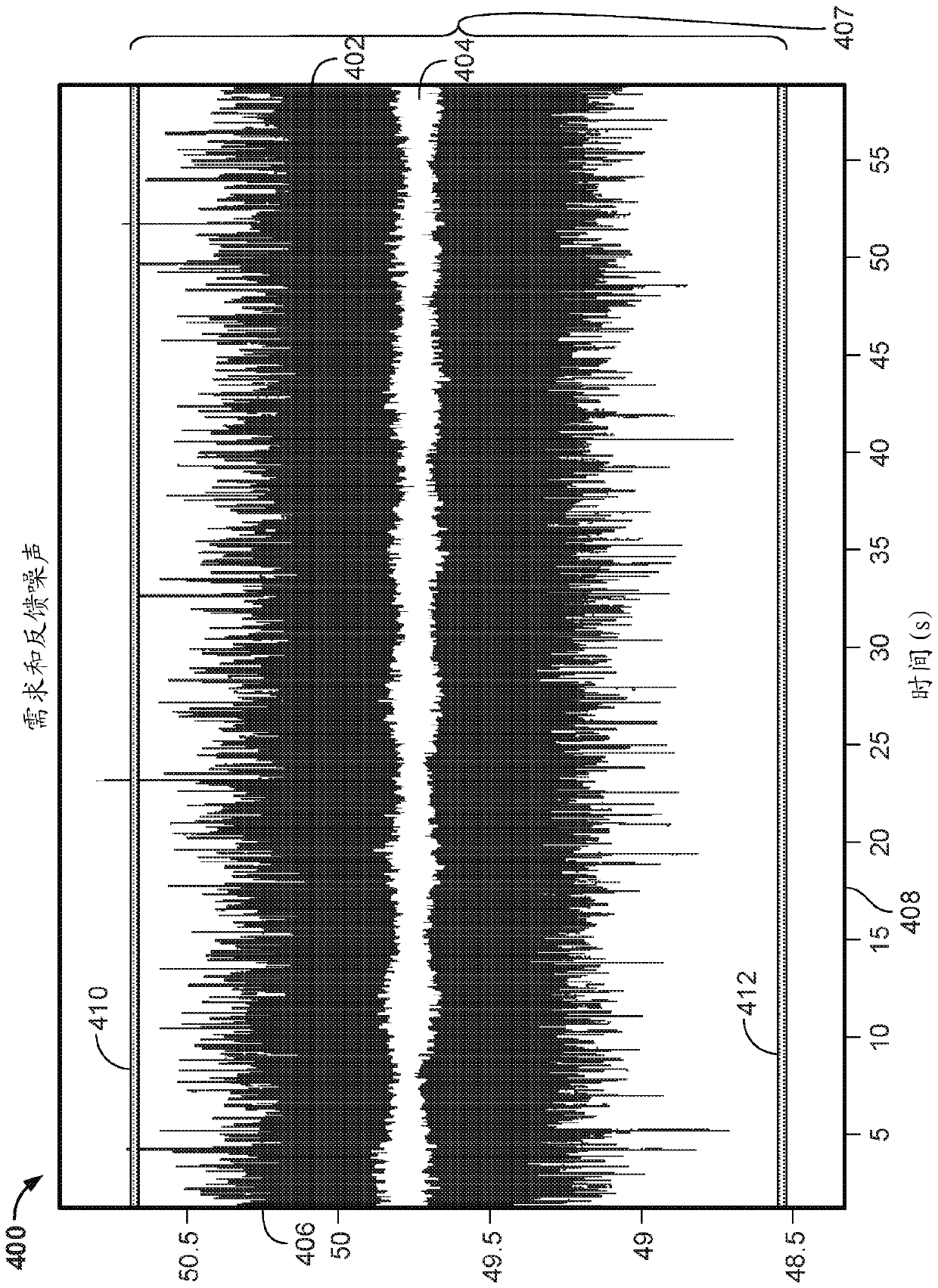

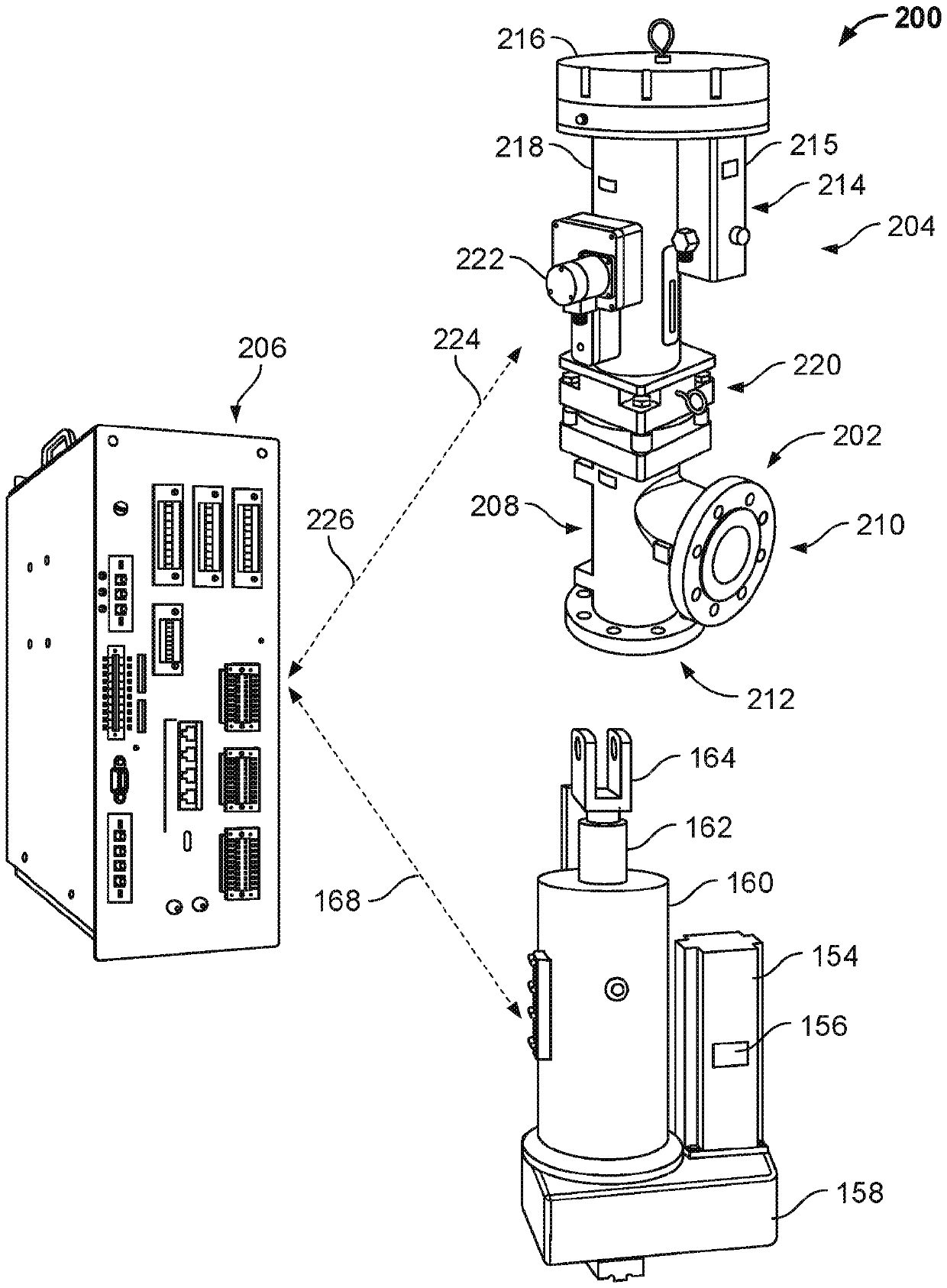

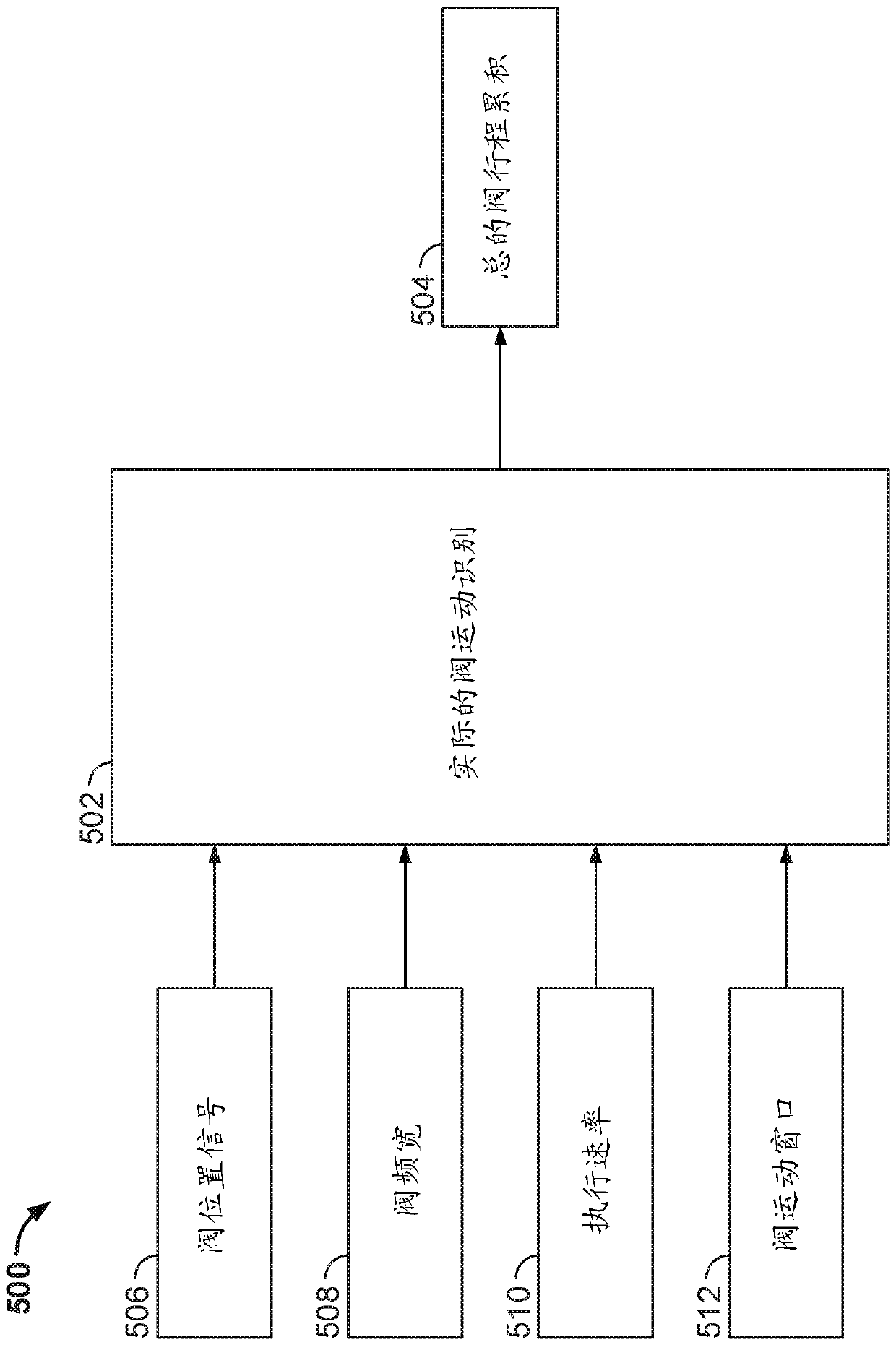

[0023] Various embodiments of the present disclosure relate to diagnostic and prognostic techniques for turbine control devices such as fuel control valves and variable vane actuators. In particular, these embodiments contemplate solving problems by accurately predicting and detecting wear on various components of a turbine control device such as seals, motors, drive trains, gear sets, bearings, and guide rods. Increasing the accuracy of wear detection for high wear system components can save time and money by preventing unplanned outages, while also ensuring operational efficiency, productivity and safety. Certain embodiments described herein may address these issues by tracking the total travel distance of the control device over time as an accumulation of actual device motion (eg, "actual valve motion" or "actual actuator motion"). problems and realize these advantages. Actual device motion corresponds to the detected device travel distance where wear of a particular compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com