Winding device of drawbench

A technology of winding device and wire drawing machine, which is applied in the field of wire drawing machine, can solve problems such as easy to be broken, finished wire broken, wire broken, etc., to achieve the effect of preventing being broken, ensuring continuity and improving winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

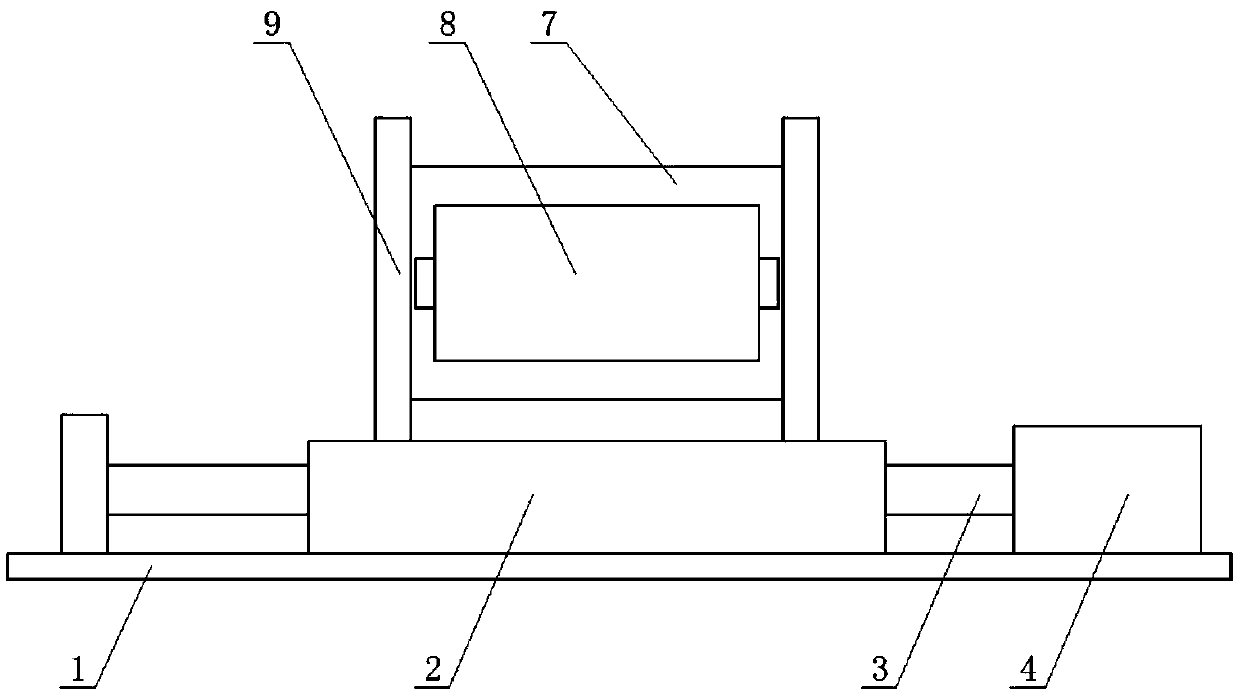

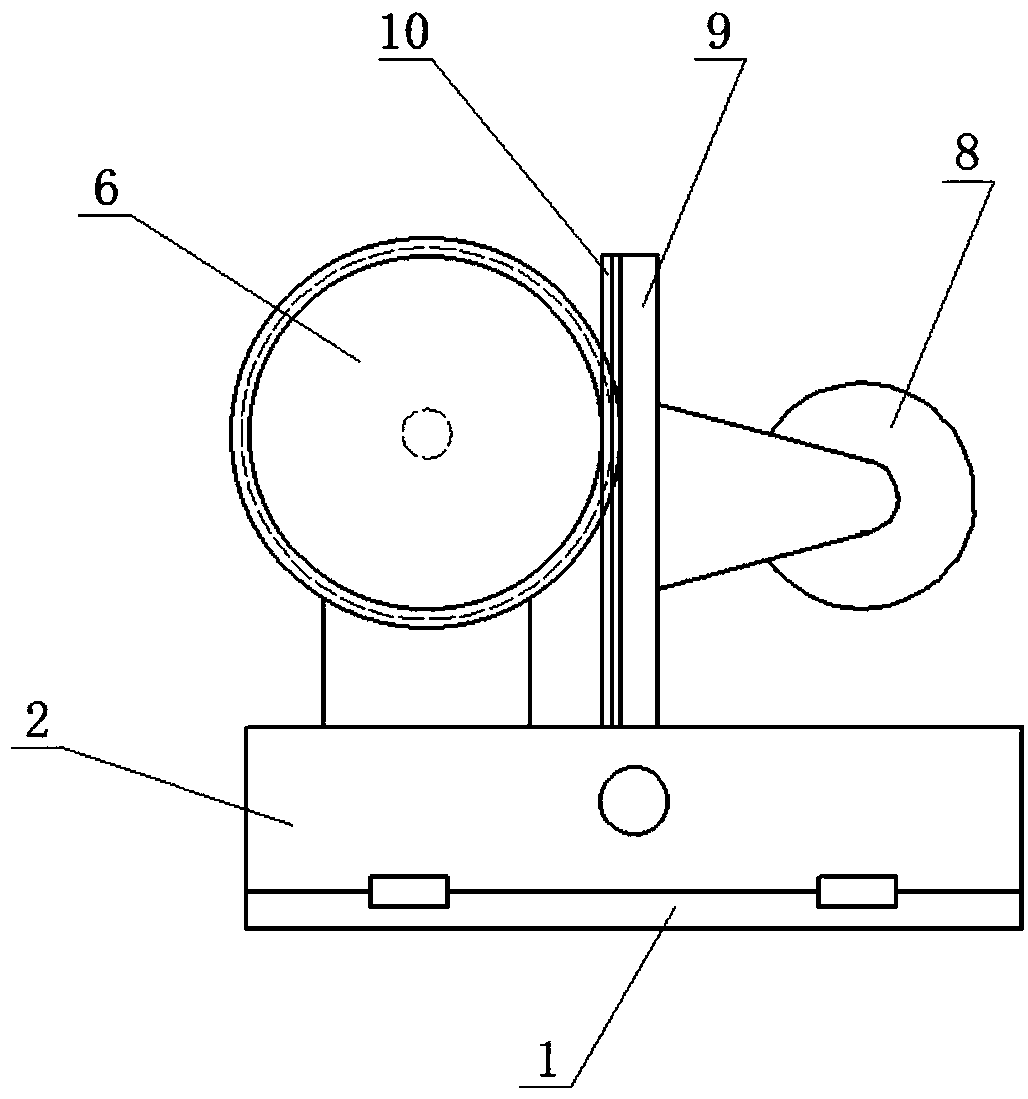

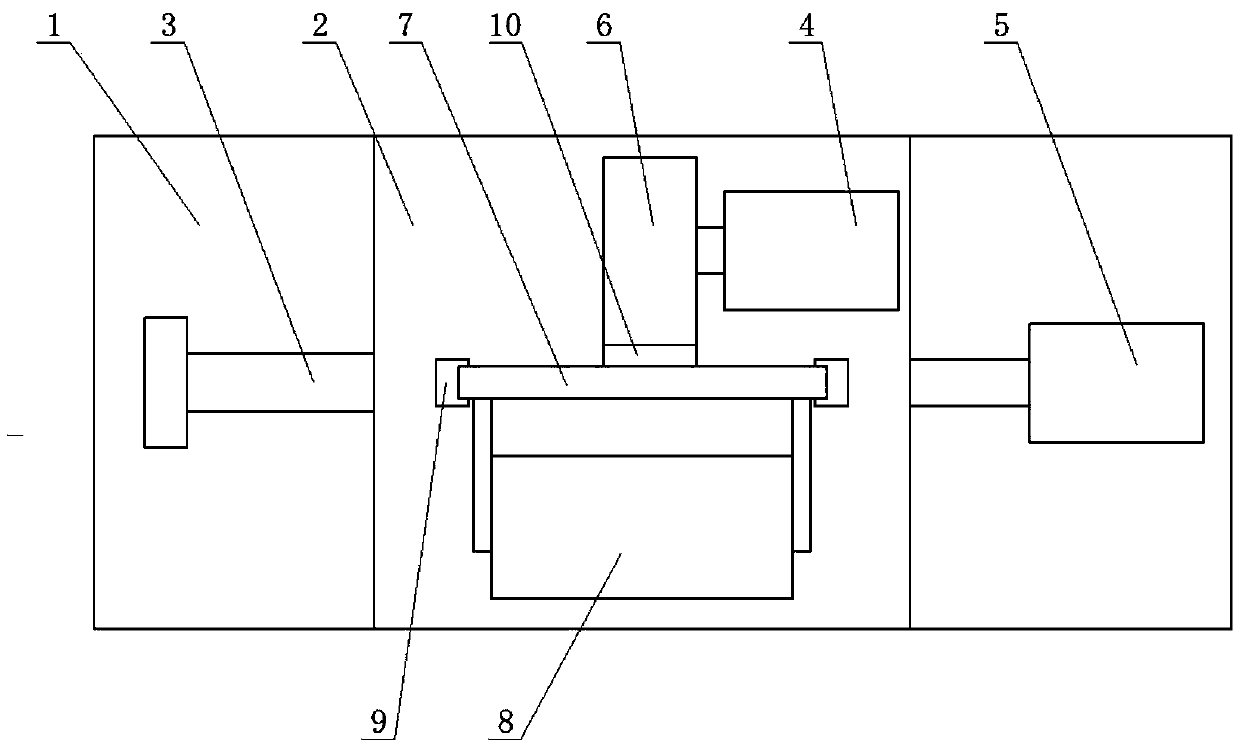

[0018] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a wire drawing machine rewinding device, including a base plate 1, a workbench 2, a ball screw 3, a drive motor A4, a drive motor B5, a gear 6, a vertical plate 7 and a reel 8, and the ball screw 3 Both ends are installed on the base plate 1 through the bearing seat, the drive motor A4 is fixedly installed on the base plate 1, the workbench 2 is set on the ball screw 3, the end of the ball screw 3 is connected with the output shaft of the drive motor A4, and the drive motor B5 is installed on the workbench 2, and a pair of pillars 9 are erected on the workbench 2, and the rails arranged along the vertical direction are arranged on the pillars 9. The two ends of the tube 8 are installed on the front side of the vertical plate 7 through the bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com