Sliding block anti-receding structure for injection mold

A technology for injection molds and sliders, which is applied in the field of anti-retraction structures for sliders used in injection molds, and can solve problems such as flailing, mold development failure, and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with the following examples.

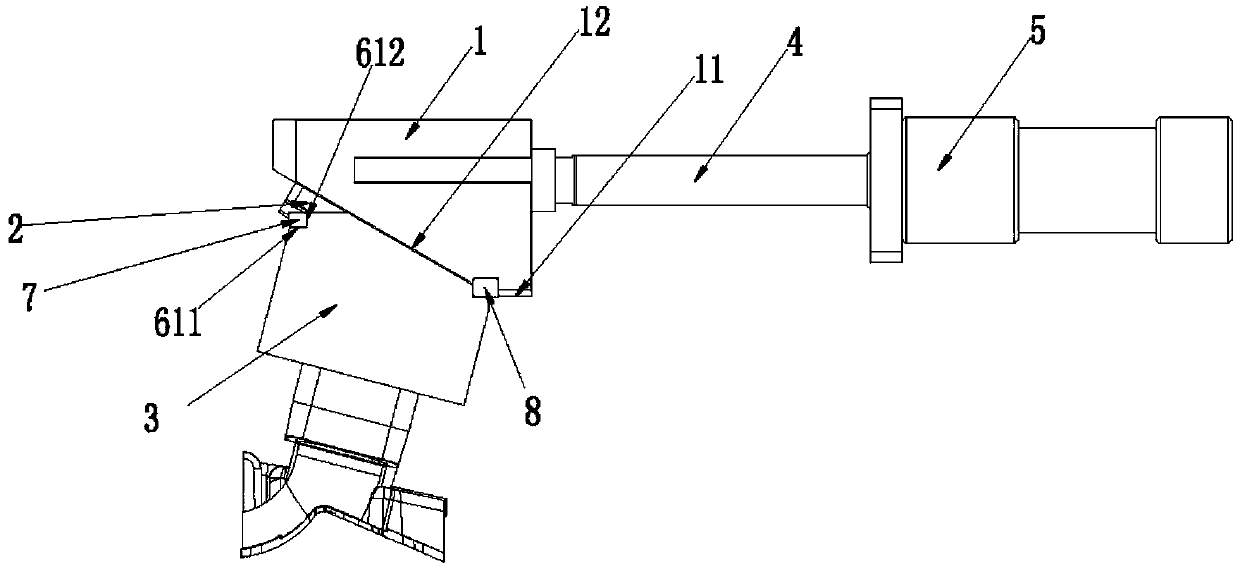

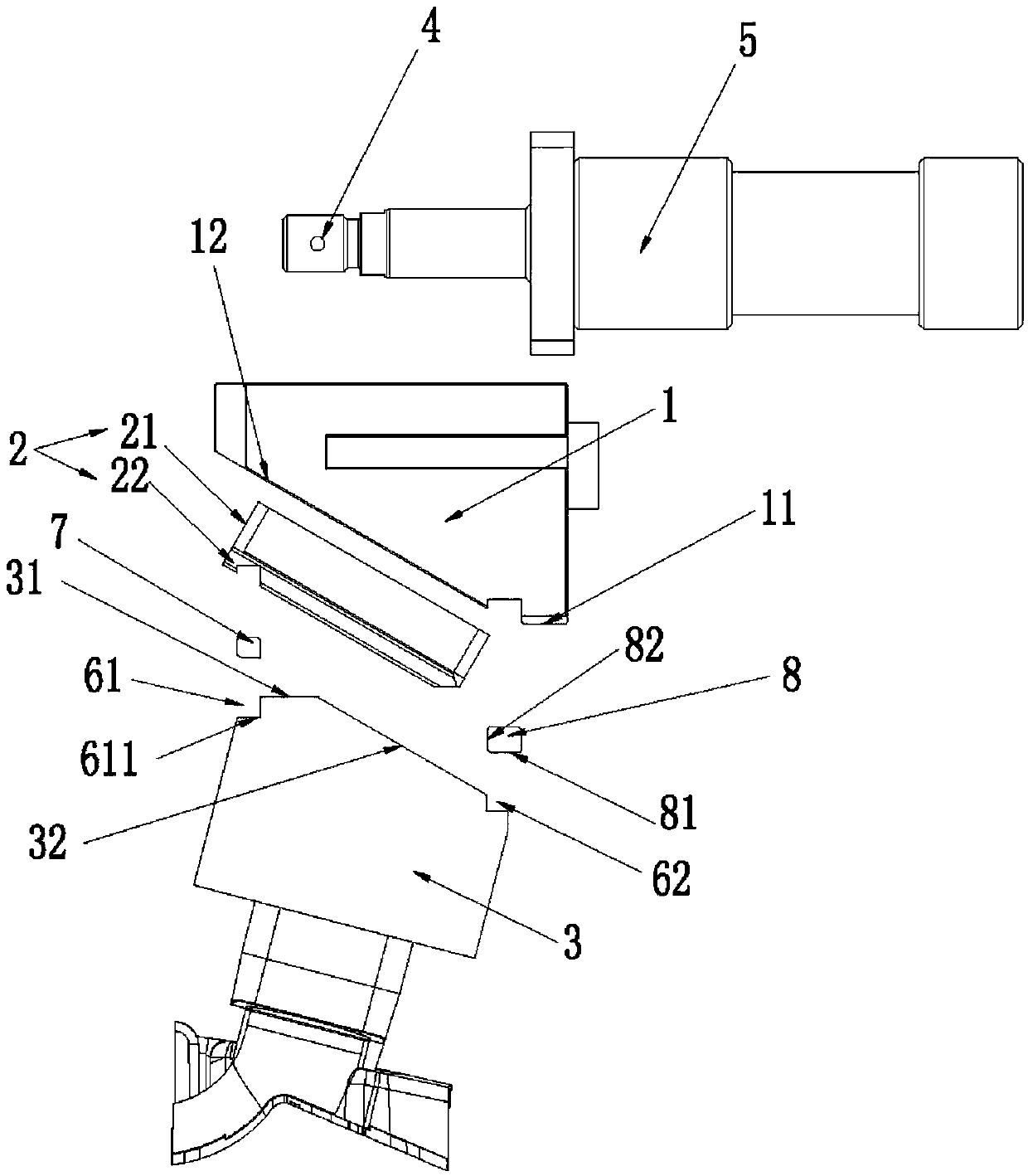

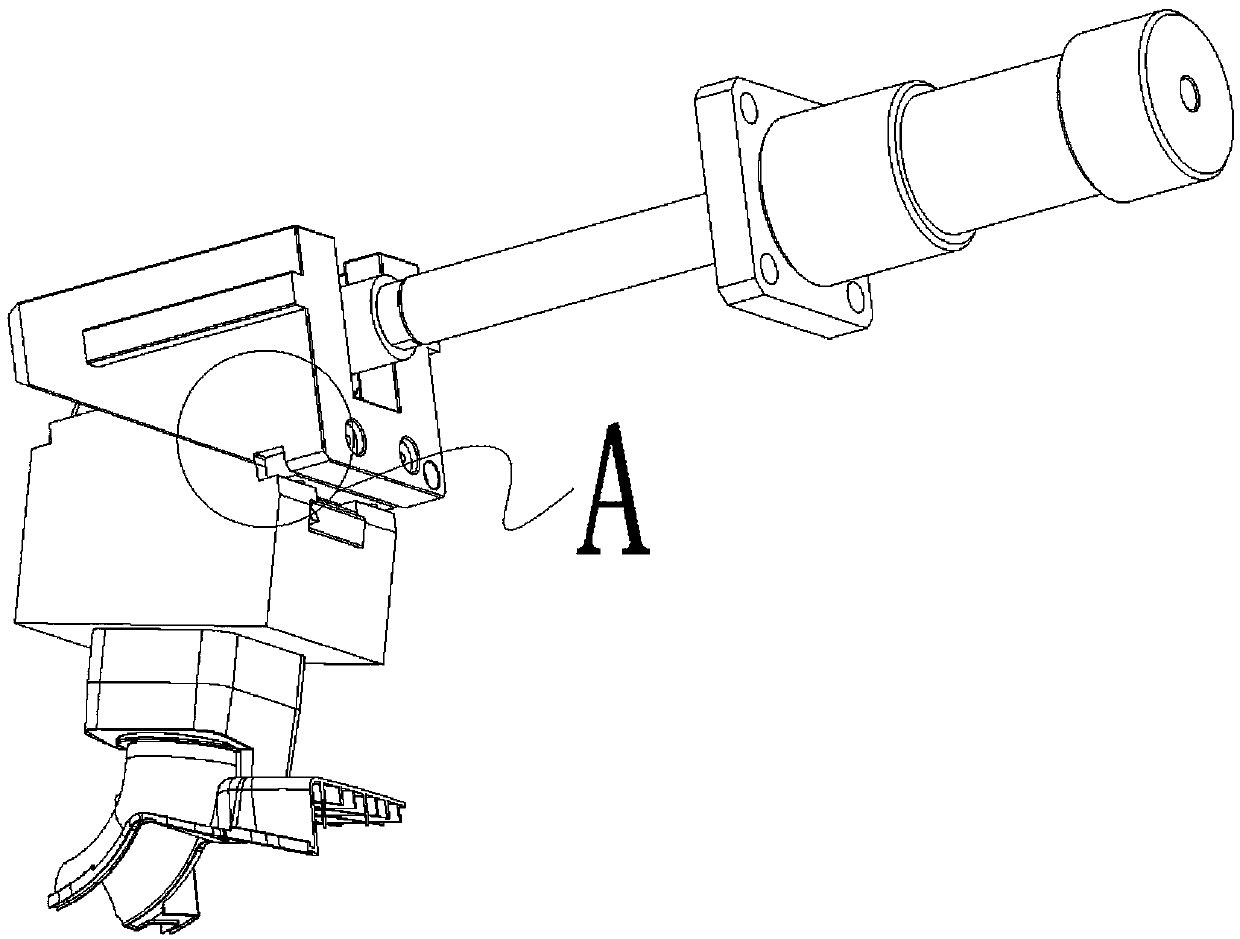

[0021] A specific implementation of the slider anti-retreat structure for an injection mold of the present invention, such as figure 1 and figure 2 As shown, it includes a hydraulic cylinder 5, a linkage seat 1, a slider 3 and a T-shaped block 2. The piston shaft 4 of the hydraulic cylinder 5 is fixedly connected to the linkage seat 1, and the bottom end surface of the linkage seat 1 is formed by a horizontal first plane 11 and an inclined Composed of the first slope 12, the longitudinal section 21 of the T-shaped block 2 is inserted and fixed on the first slope 12 of the linkage seat 1, see Figure 7 , the slider 3 is provided with a T-shaped slot 33. In the assembled state, the transverse section 22 of the T-shaped block 2 is inserted into the T-shaped slot 33 and can slide relative to the T-shaped slot 33. The top surface of the slider 3 is formed by It consists of a second pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com