An embedded mobile station cable steering mechanism

A technology of steering mechanism and mobile platform, which is applied in the field of cables, which can solve the problems of operators tripping and cables being easily scratched and broken by foreign objects, so as to avoid potential safety hazards, facilitate storage and prolong working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

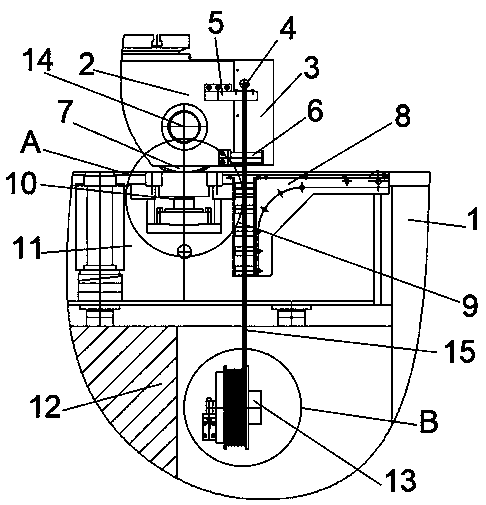

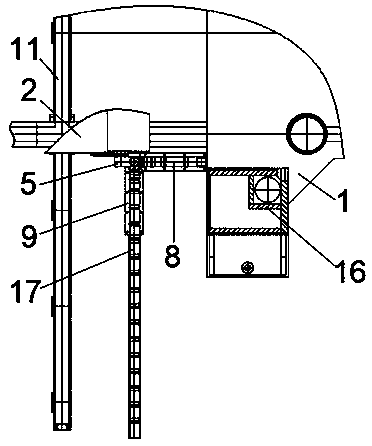

[0029] Embodiment 1: refer to figure 1 and 2 ;

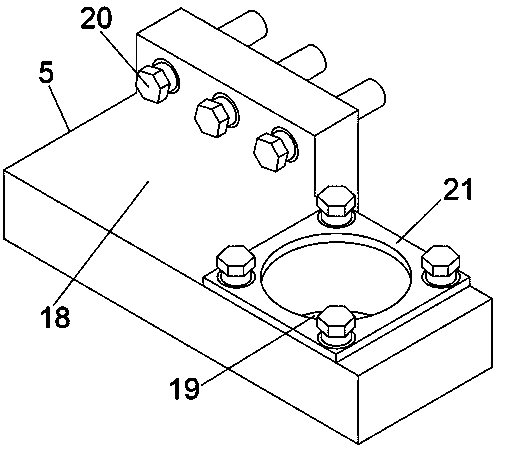

[0030]An embedded mobile platform cable steering mechanism, including a bottom beam 1, a mobile platform 2 and a foundation 12, characterized in that it also includes a wire take-up device 13, and a cable 15 is wound on the wire take-up device 13, and the bottom beam 1 is surrounded by The upright column 16 is fixedly connected to the upper surface of the ground 12, and a guide rail 11 is fixedly installed on one side of the bottom beam 1, and the guide rail 11 is fixedly connected to the upper surface of the foundation 12 through positioning bolts. A cable perforation 4 is provided, and a drive motor is arranged in the motor box 3. The end of the cable 15 runs through the cable perforation 4 and the clamping bracket 5 is fixedly connected with the drive motor. 14 is electrically connected to the drive motor, the drive shaft 14 is fixedly connected to the end surface of the guide rail wheel 7, the lower end rim of the guide ra...

Embodiment 2

[0035] Embodiment 2: refer to Figure 4 and 5 , the basis of the embodiment 1 is different in that;

[0036] Be provided with groove below turning point of inflection, and rotating device 10 comprises rotating block 22 and ring supporting chute 25, and ring supporting chute 25 outer wall is fixedly connected with groove 10 upper notch inner wall, and ring supporting chute 25 is connected with rotating The block 22 peripheral surfaces are slidingly connected, the middle part of the lower surface of the rotating block 22 is fixedly connected with the upper end of the connecting shaft 24, and the lower end of the connecting shaft 24 is fixedly connected with the rotation sensor 23, and the rotation sensor 23 is fixedly installed at the bottom of the groove.

[0037] The take-up device 13 includes a grooved ring 26 and an induction motor 29, the groove surface of the grooved ring 26 is connected with the cable 15, the middle part of the grooved ring 26 is fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com