Prefabricated assembly-type stair module-type combined die and installing method thereof

A combined mold and prefabricated assembly technology, which is applied in the direction of mold fixtures, stairs, molds, etc., can solve the problems of unfavorable assembly structure promotion, increase the operating cost of manufacturers, and many specifications and sizes of prefabricated stairs, so as to shorten the construction period and rework The effect of reducing the efficiency and reducing the cost of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the drawings and specific embodiments.

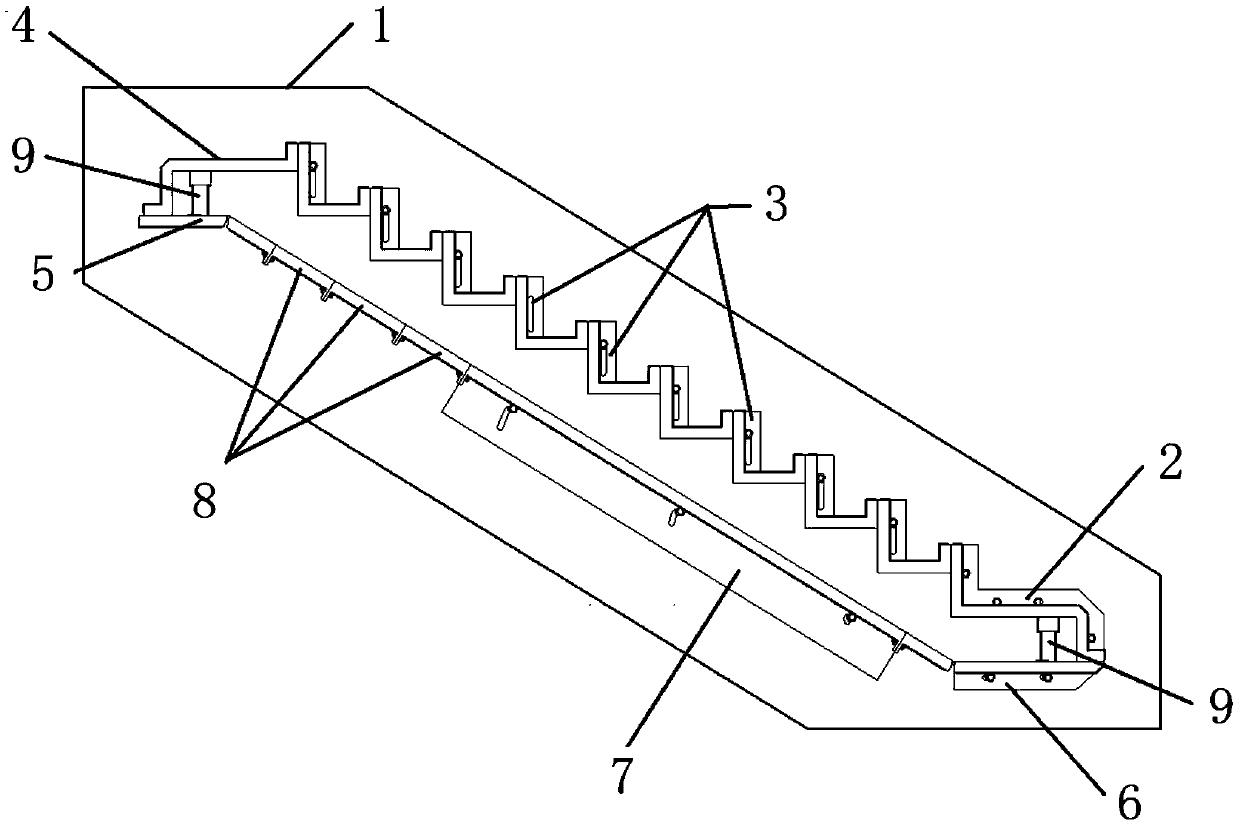

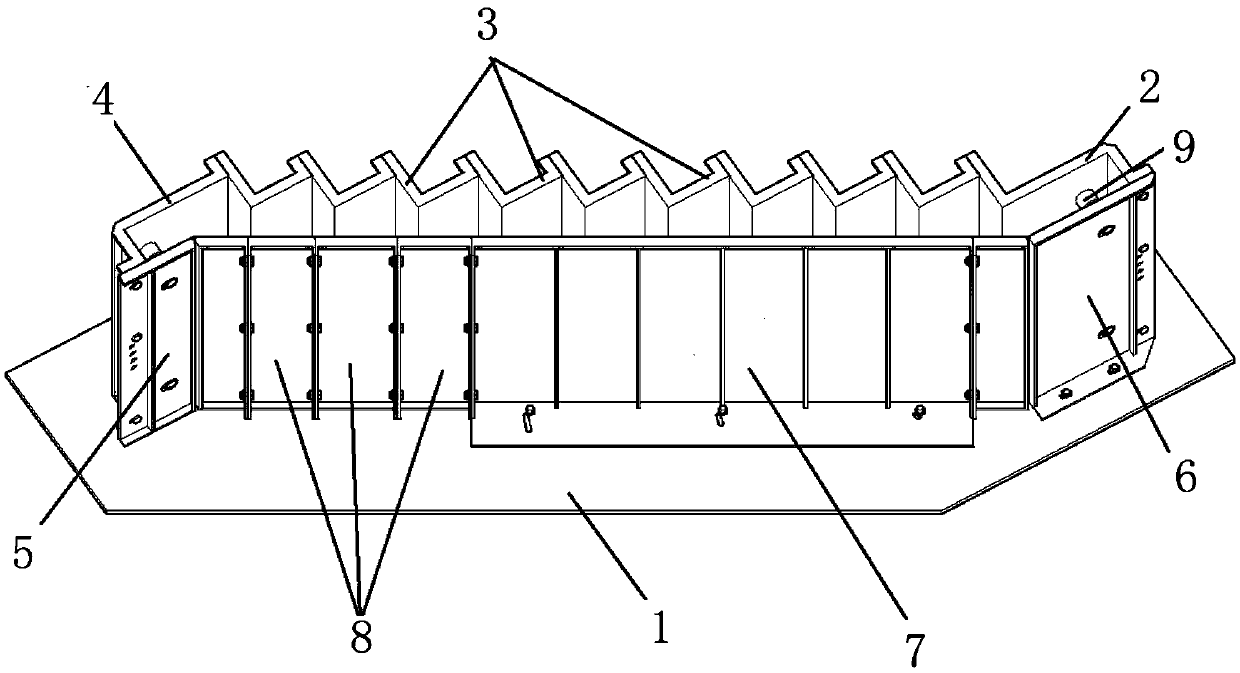

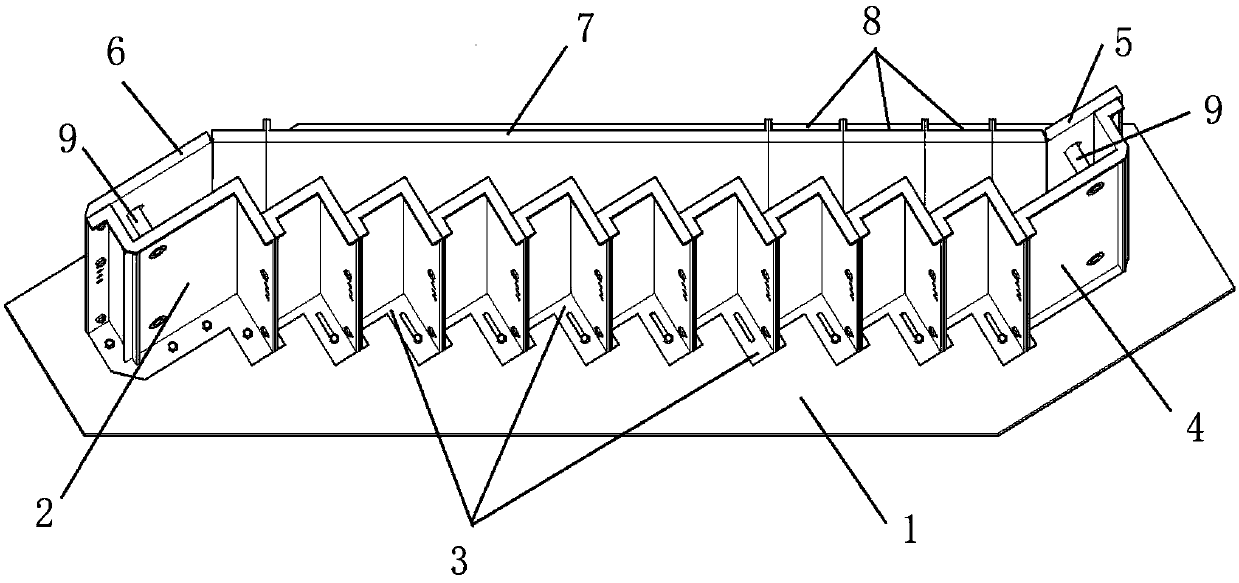

[0043] Such as Figure 1 to Figure 13 As shown, a prefabricated modular stair modular combined mold includes a base 1, a stepping standard module 3, a lower platform upper surface module 2, a lower platform lower surface rotation module 6, an upper platform upper surface module 4, and an upper platform lower surface rotation Module 5, lower surface general module 7 and lower surface adjustment module 8;

[0044] The base 1 is equipped with fixing bolts for installing each ladder module. The upper surface module 2 of the lower platform is the bottommost ladder module. The side end plate connected to the base 1 is provided with a number of fixing holes 13 which are in line with the oblique upper end stepping standard. A number of positioning holes 12 and sliding holes 11 are arranged on the vertical end surface connected to the module 3, and a number of fixing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com