Stepped set-back model large glass curtain wall construction method

A glass curtain wall and construction method technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of difficult operation and installation of glass panels, inability to deploy construction machinery, and limited space for hanging baskets, so as to increase convenience and improve hanging baskets. Construction technology, easy to dismantle and modify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

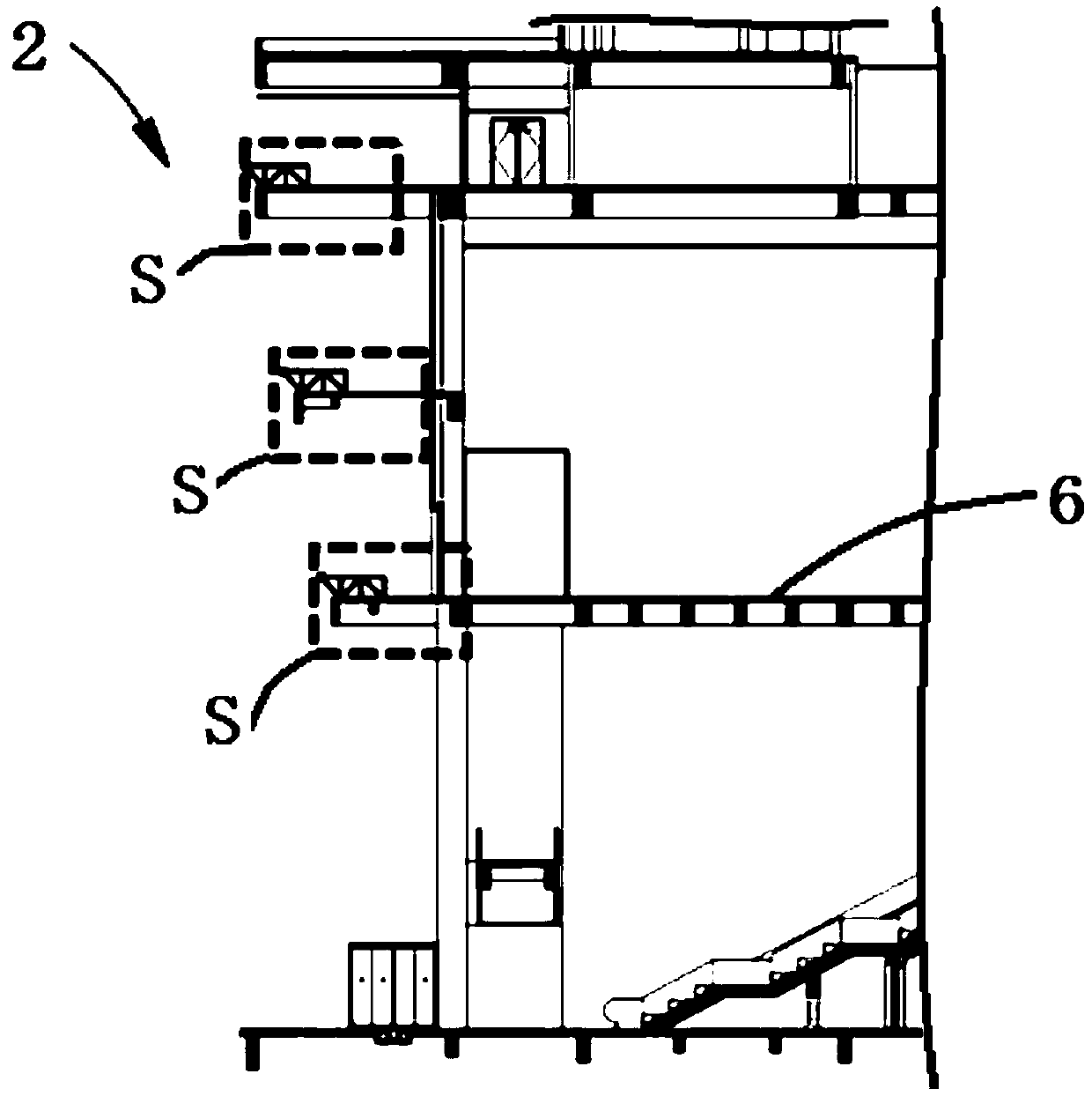

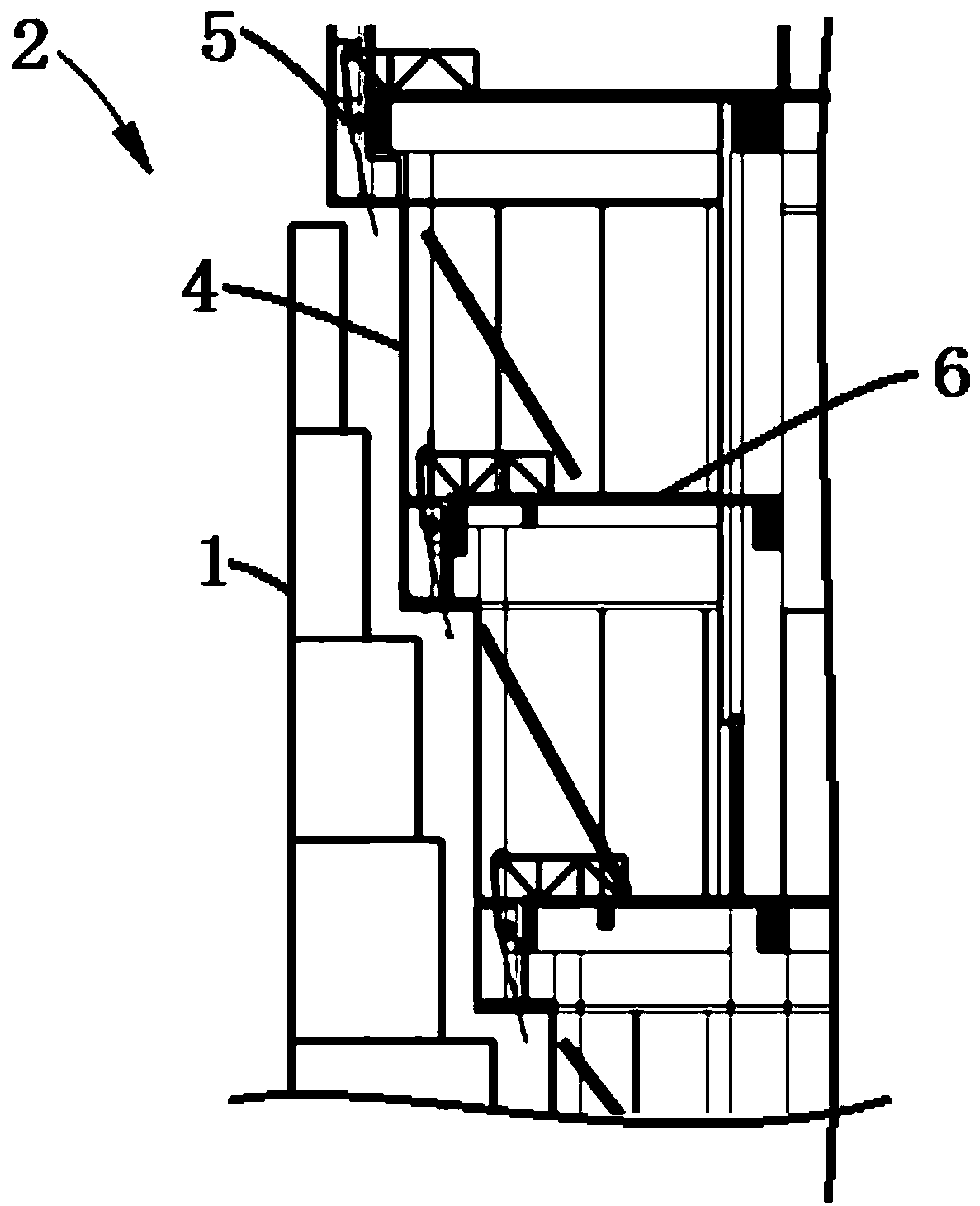

[0023] see Figure 1 to Figure 3 As shown, the present invention provides a kind of step-back large glass curtain wall construction method, comprising the following steps:

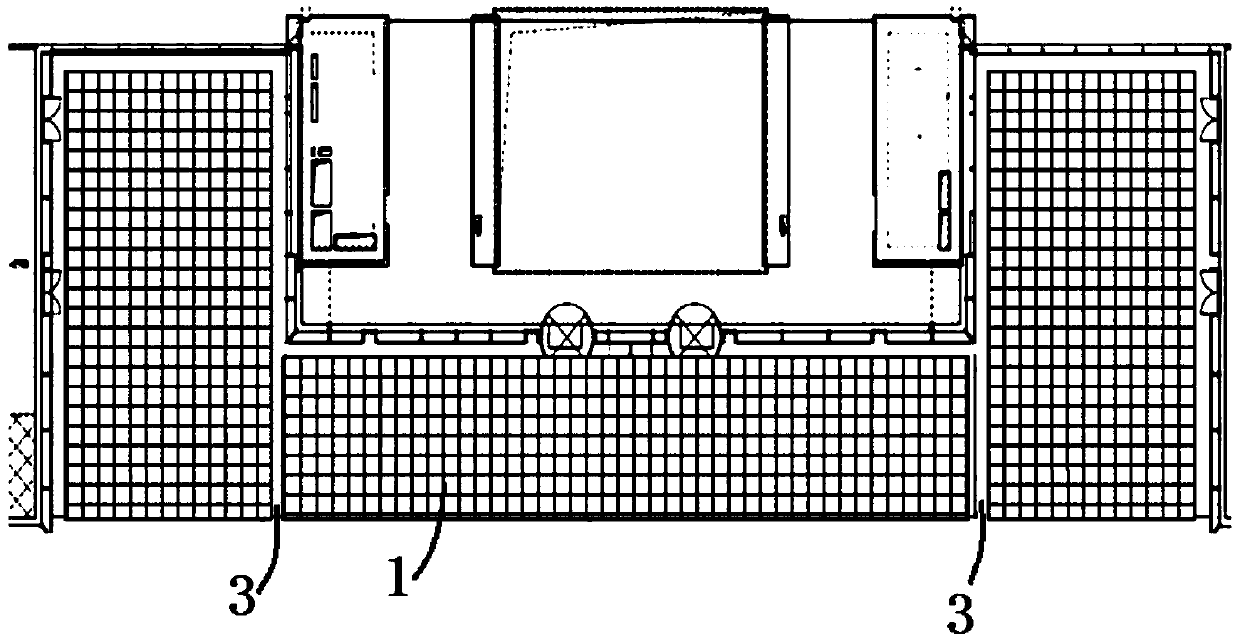

[0024] S1: Set up a stepped scaffold 1 under the glass curtain wall to be installed, the stepped scaffold 1 is erected along the finished surface of the glass curtain wall 2, and there is a gap between the stepped scaffold 1 and the glass curtain wall 2 for the constructor Operating space for operation; in the embodiment of the present invention, side scaffolding is set up on both sides of the glass curtain wall to be installed to facilitate the installation of glass on the side elevation of the glass curtain wall; the glass curtain wall is a framed glass curtain wall;

[0025] Specifically, vertical transportation channels 3 are reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com