High-frequency load-bearing hydraulic cylinder

A hydraulic cylinder and high-frequency technology, applied in the field of hydraulic cylinders, can solve problems such as limited service life, achieve long service life, avoid rigid impact, and reduce rebound force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

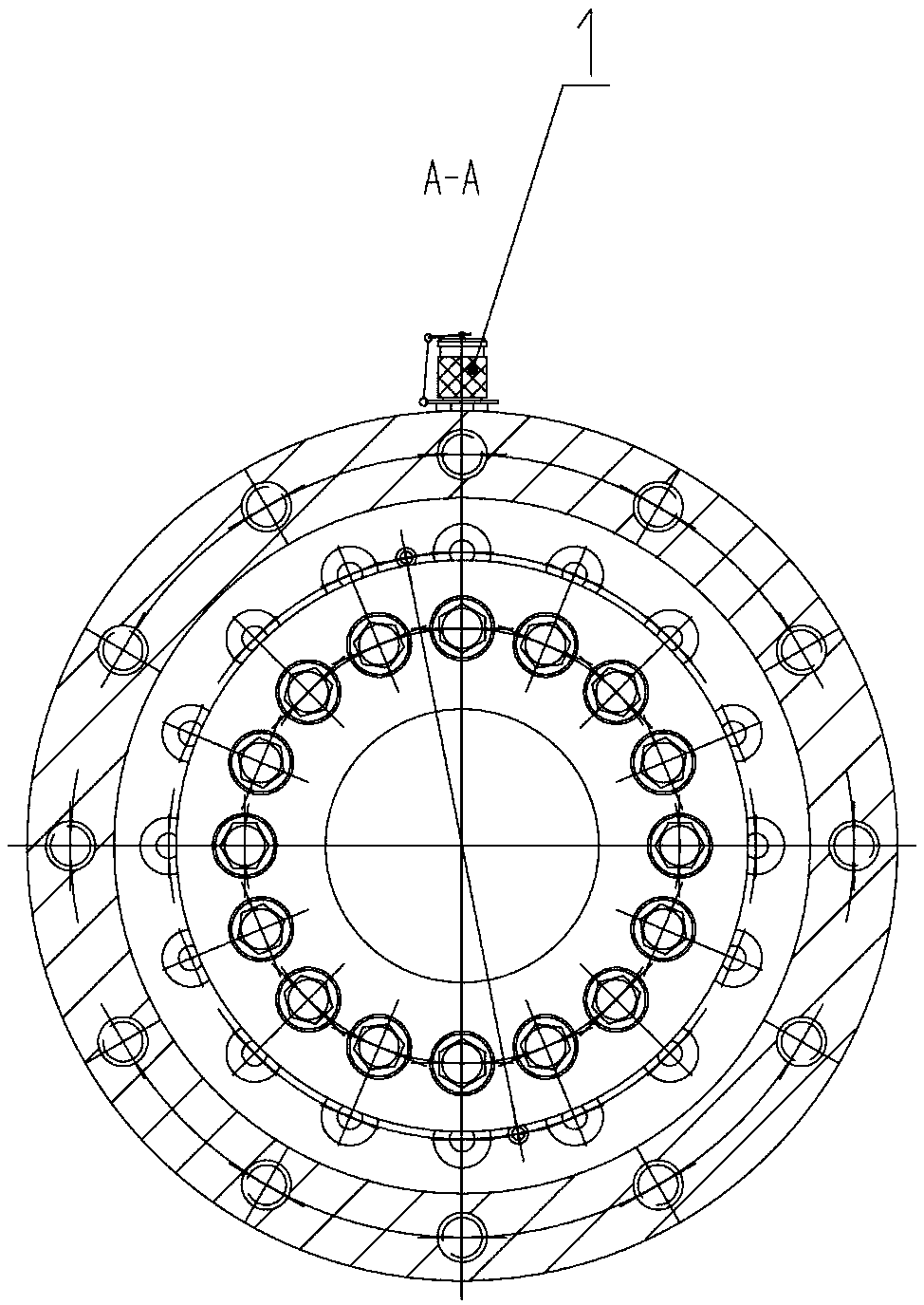

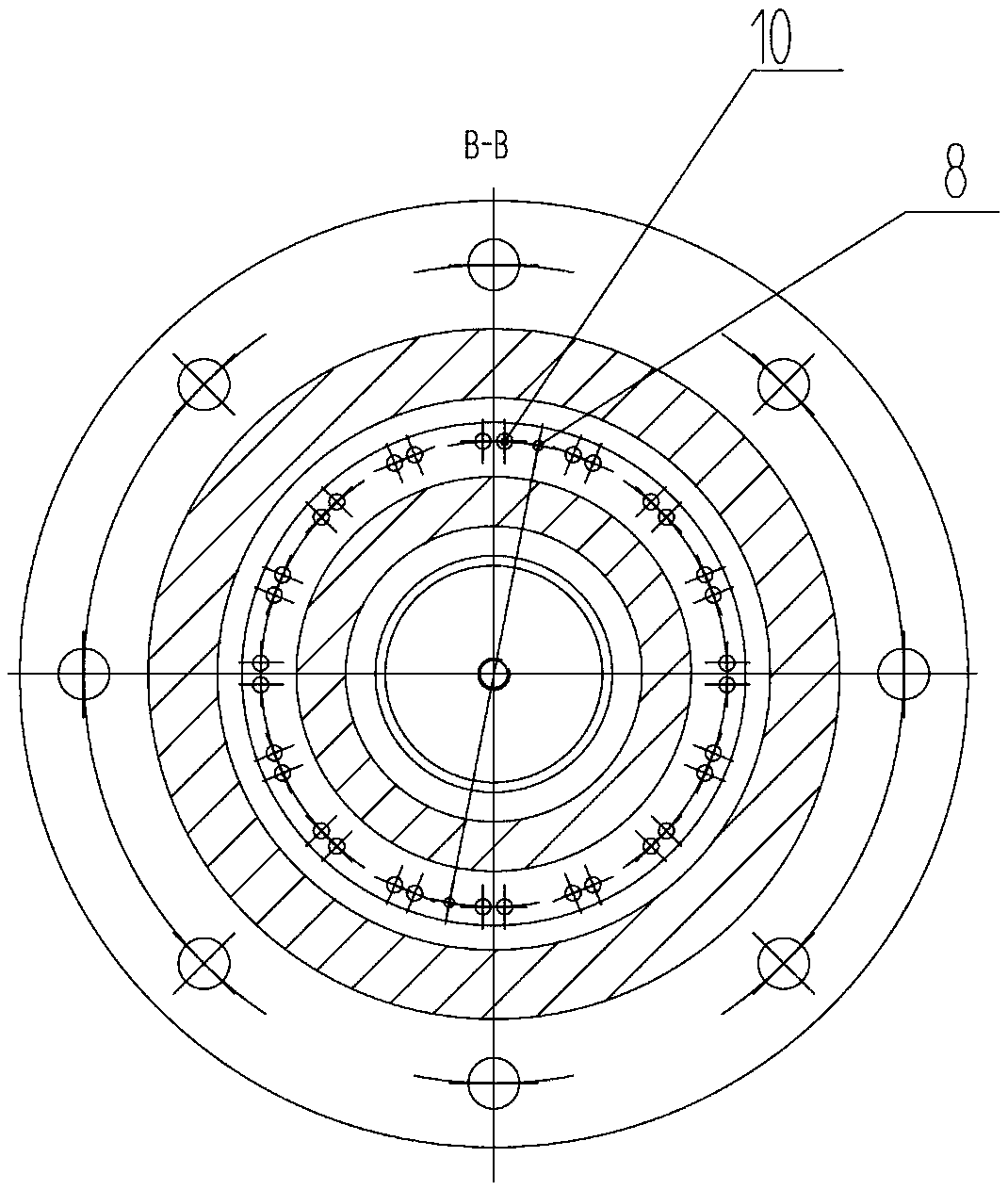

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

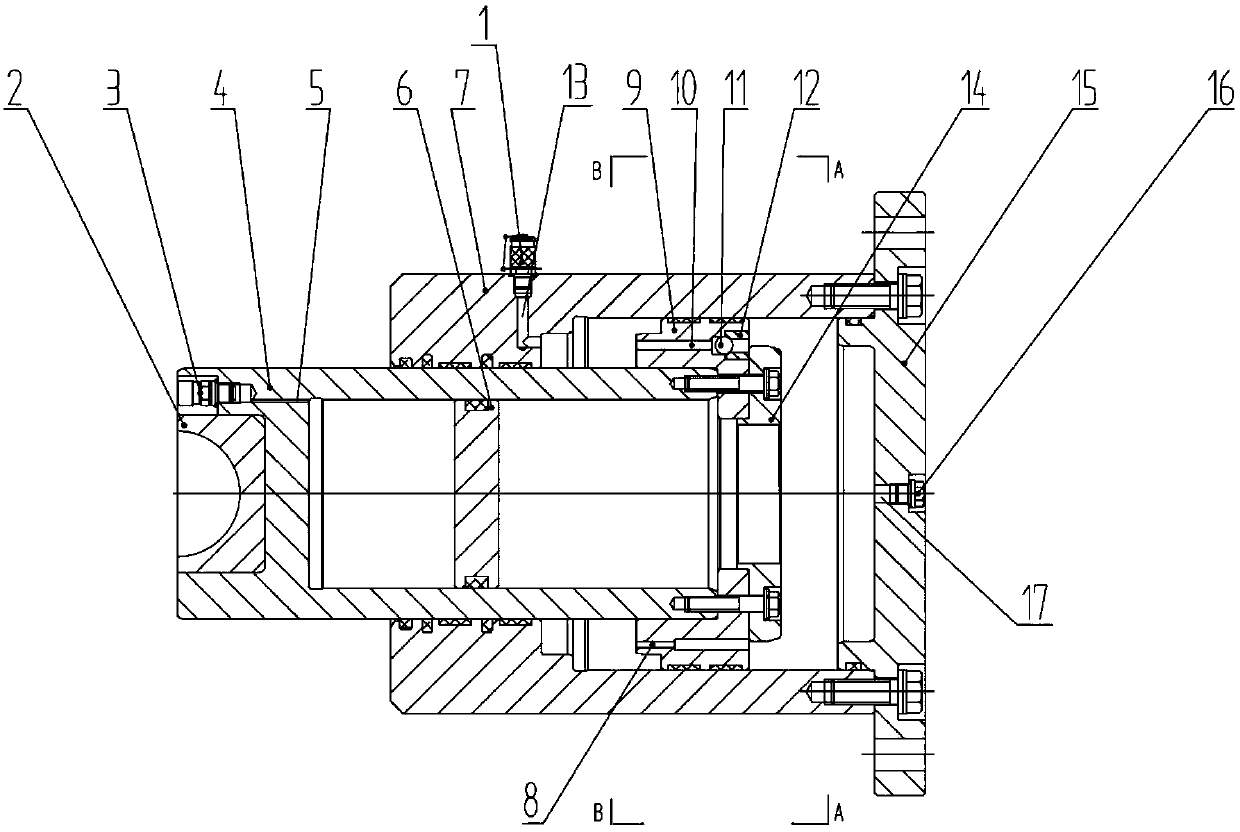

[0026] This embodiment provides a high-frequency loaded hydraulic cylinder, see the attached Figure 1-3 , including: plug 1, impacted body 2, inflation valve 3, piston rod 4, gas piston 6, cylinder body 7, piston 9, check valve 11, check valve seat 12, buffer body 14, cylinder bottom 15 and Oil-filled screw plug 16;

[0027] The cylinder body 7 is a cylindrical body with openings at both ends, and the cylinder body 7 is processed with an oil and gas port 13 communicating with its inner cavity, and a plug 1 is installed on the oil and gas port 13 to close the oil and gas port 13;

[0028] The cylinder bottom 15 is fixed on one end of the cylinder body 7 by screws, and the end opening of the cylinder body 7 is closed, and the cylinder bottom 15 is processed with an oil port 17 communicating with the cylinder body 7 inner cavity, and the oil port 17 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com