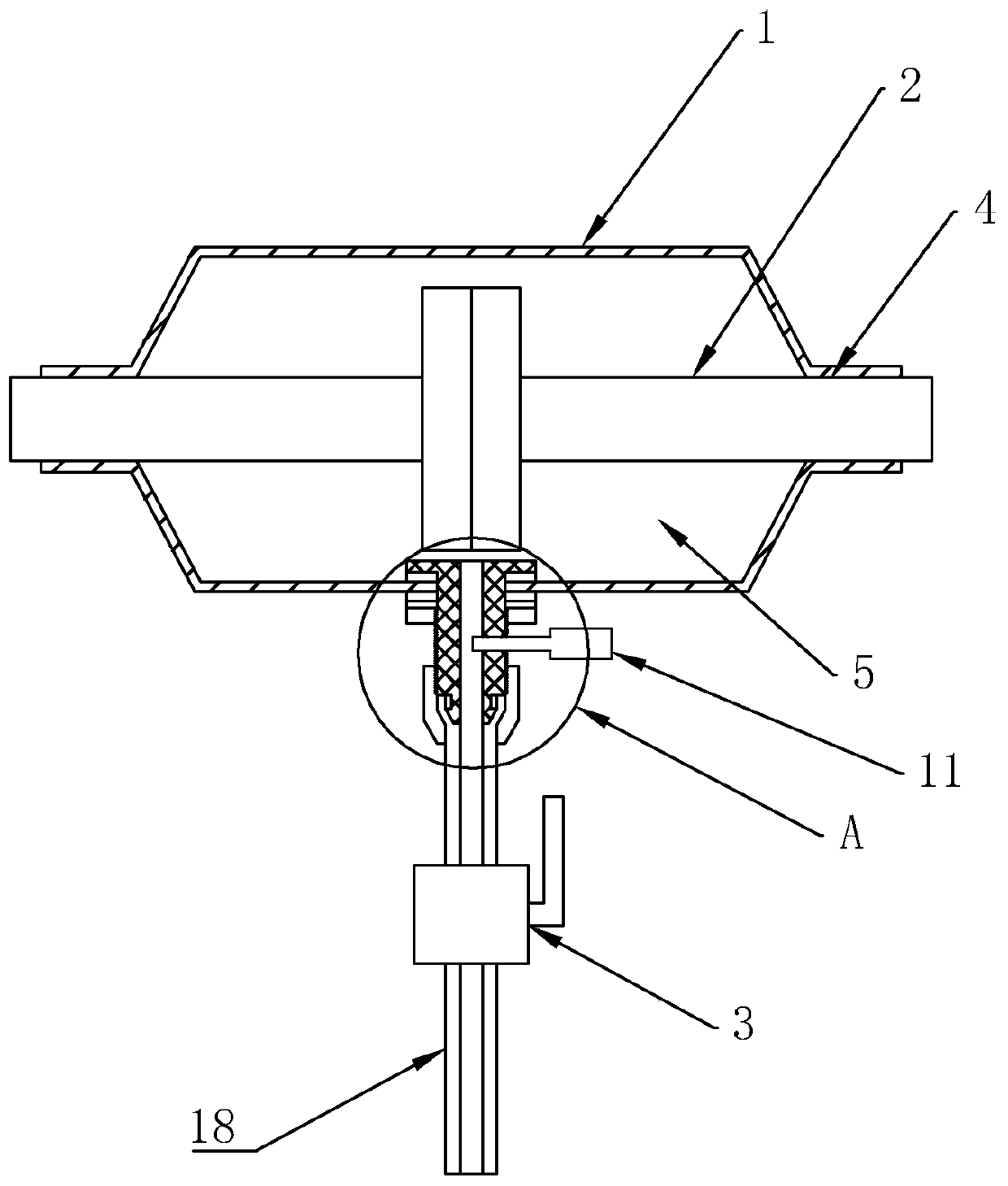

A pipeline leak detection device

A technology for detecting device and pipeline leakage, which can be used in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., and can solve problems such as danger, leakage, and toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

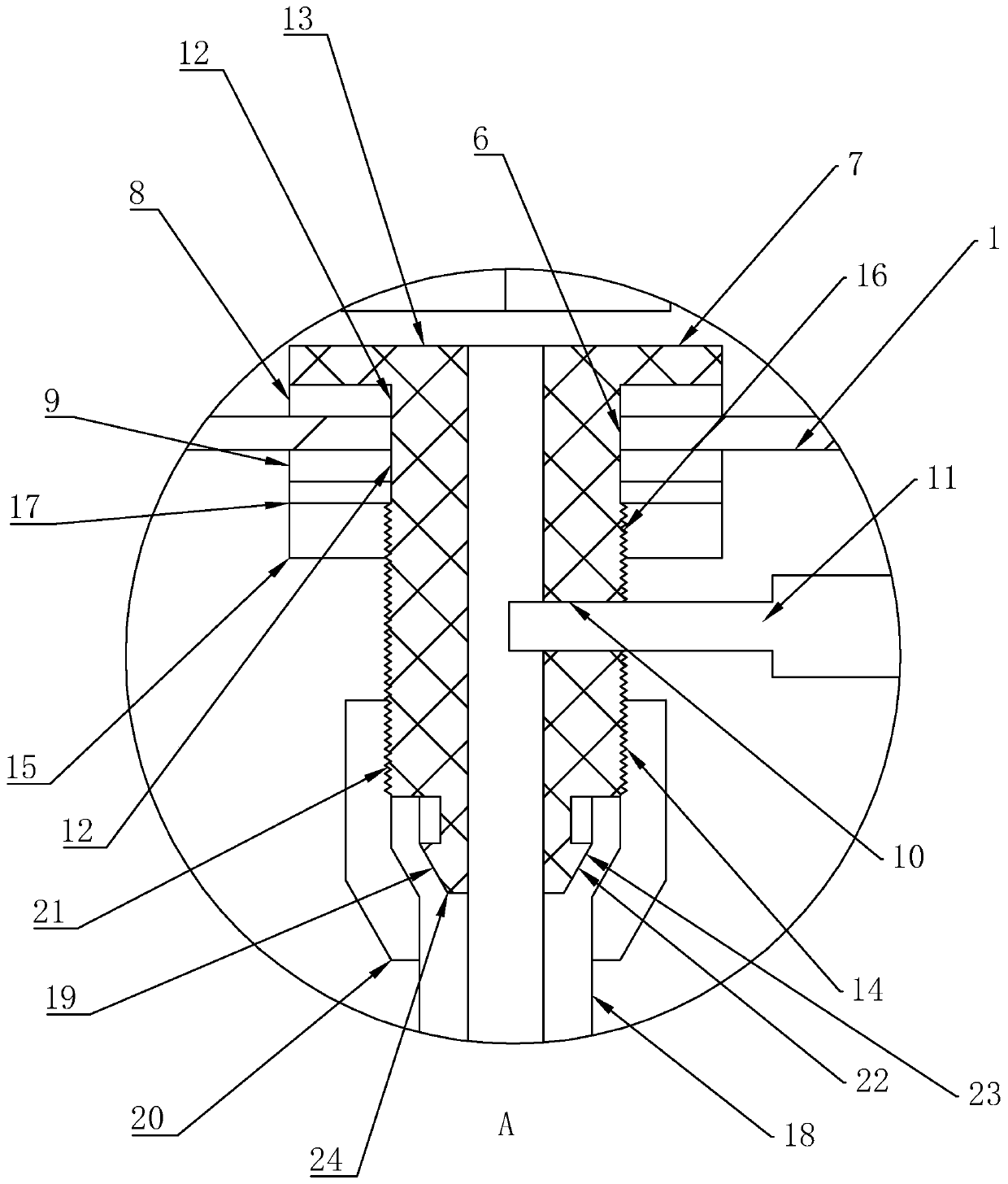

[0036] The first clamping part 8 and the second clamping part 9 are rubber blocks, and both are provided with perforations 12 for the vacuum tube 7 to pass through.

[0037] Through the above technical scheme, the rubber block is selected in the selection of the first clamping part 8 and the second clamping part 9. Through the interference fit of the rubber block, the rubber block can be deformed to better clamp the protective cover 1, and at the same time The sealing effect on the through hole 6 is improved.

[0038] As an improved specific implementation,

[0039] One end of the vacuum tube 7 located in the sealed space 5 is provided with a conflict plate 13 , and the first clamping member 8 is located between the conflict plate 13 and the protective cover 1 .

[0040] Through the above technical solution, through the setting of the conflicting plate 13, the first clamping part 8 can be resisted by the conflicting plate 13, so that there is a supporting force for the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com