High-temperature gas cooled reactor heat transfer tube inspection device

A high-temperature gas-cooled reactor and inspection device technology, which is applied in the direction of reducing greenhouse gases, monitoring of reactors and nuclear reactors, etc., can solve the problems of difficult non-destructive testing of heat transfer tubes, and achieve the effect of compact and lightweight structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

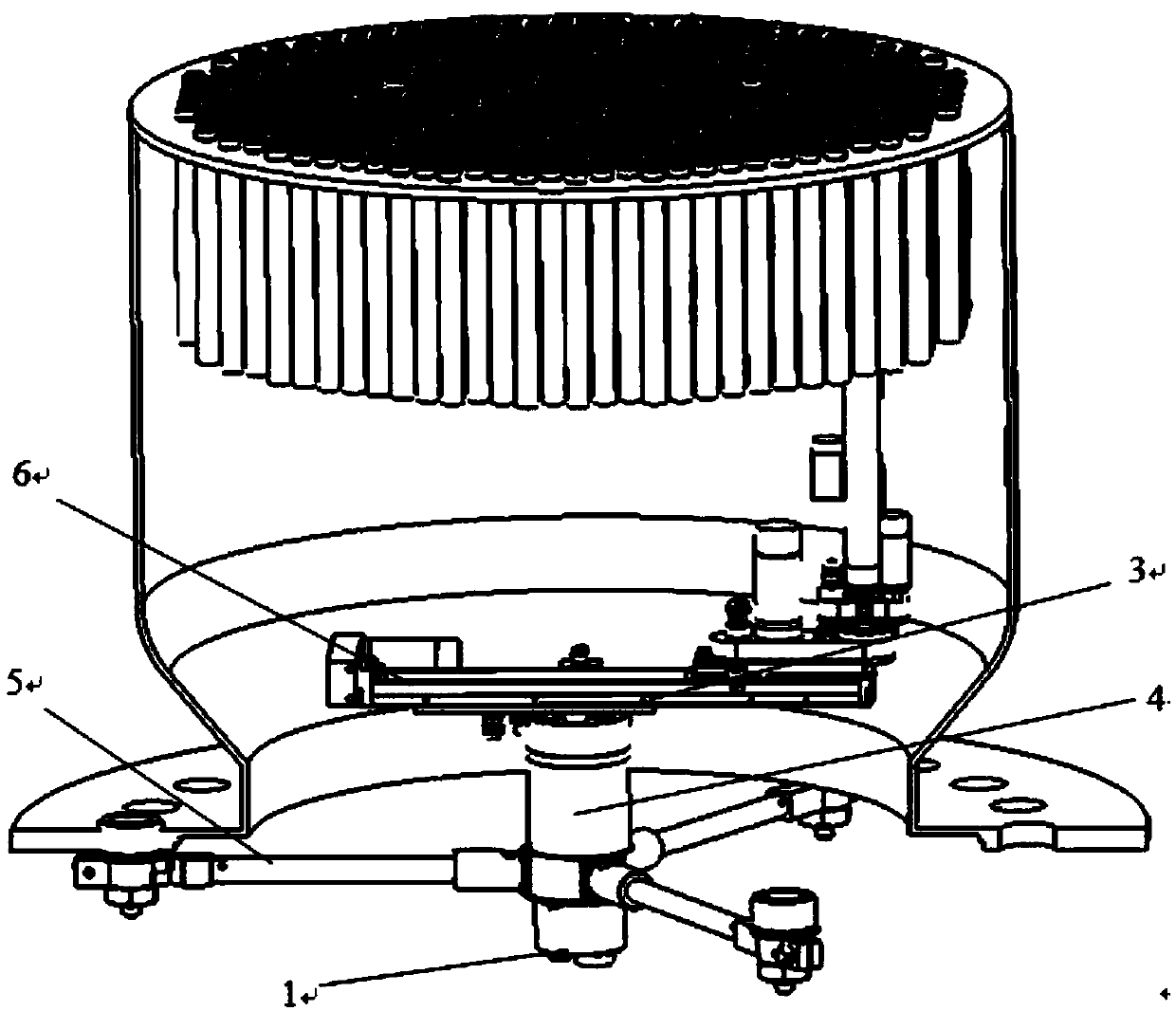

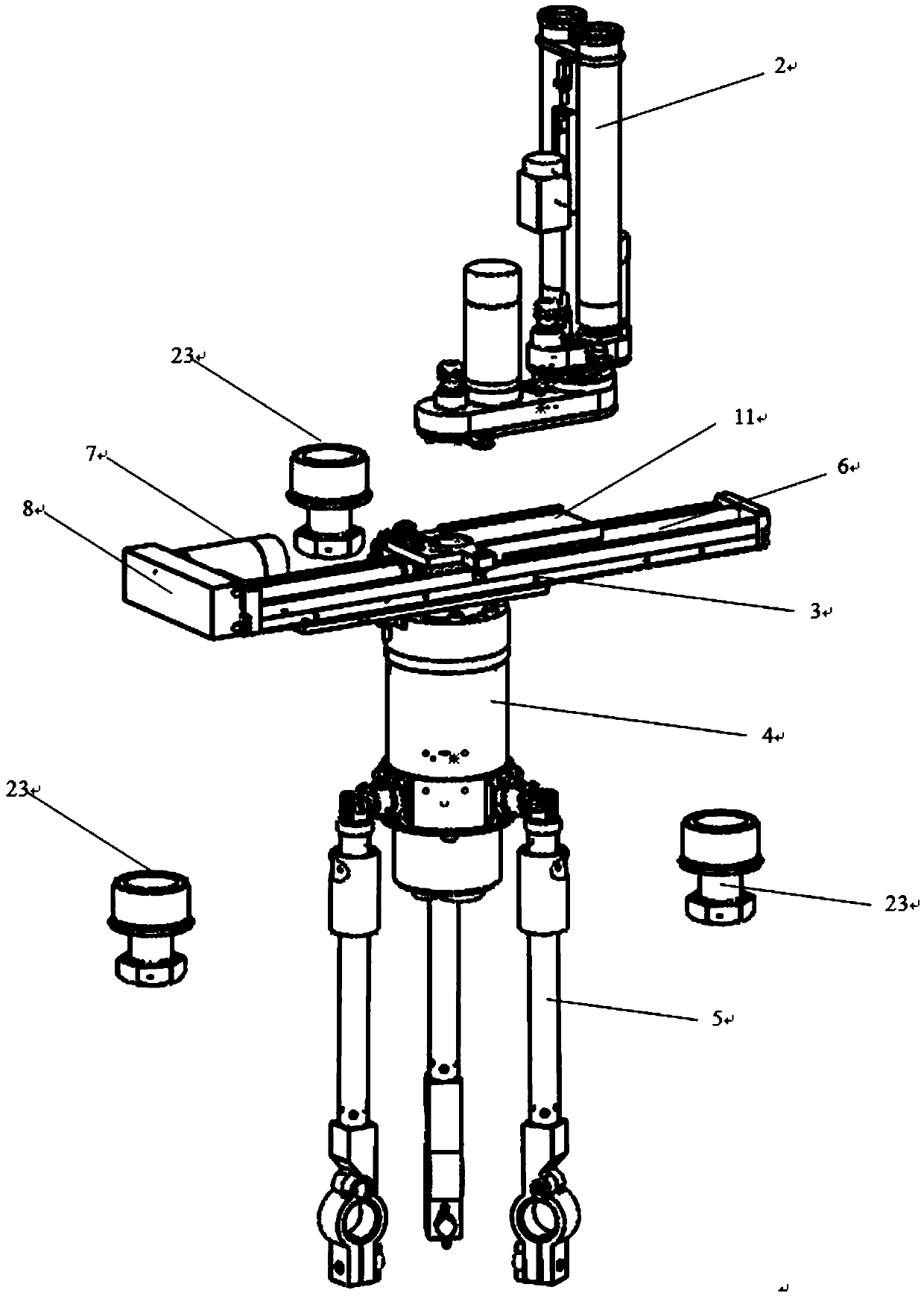

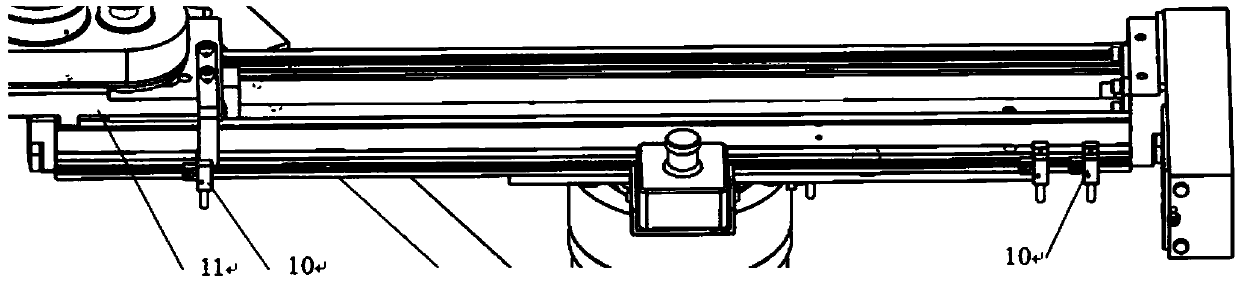

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] According to the structural characteristics of the high temperature gas-cooled reactor steam generator, the main actions of the inspection device are divided into circular motion, radial expansion and vertical lifting. This cylindrical coordinate structure makes full use of the axisymmetric features of the tube sheet and the water chamber. The inspection device realizes circular motion through the slewing mechanism, and uses the guide rail to realize radial linear sliding. The combination of the two actions can drive the suction gun to cover the entire tube sheet distribution area of holes. The vertical lift is mainly used to control the action of the suction gun.

[0034] Such as Figure 1 to Figure 7As shown, a high-temperature gas-cooled reactor heat transfer tube inspection device adopts a modular design and mainly includes a suction gun ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com