Breaker card board bounce-resistant mechanism

An anti-bounce and breaker technology, applied in the operation/release mechanism of the protection switch, parts of the protection switch, electrical components, etc., can solve the problems of increasing the rebound of the moving contact, reducing the breaking index, and reducing the effective opening distance, etc. Achieve the effect of preventing excessive springback, increasing the number of parts, and taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

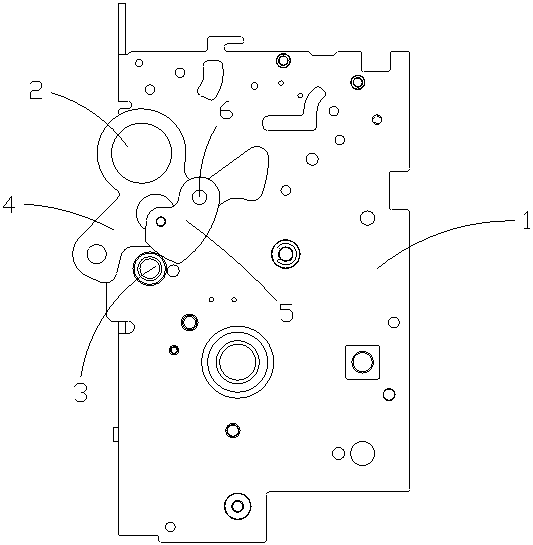

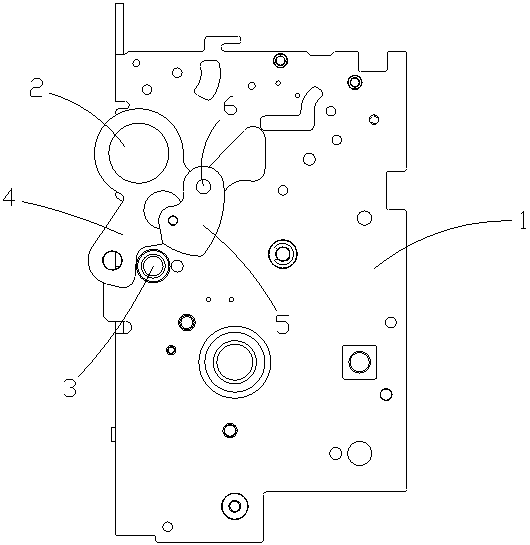

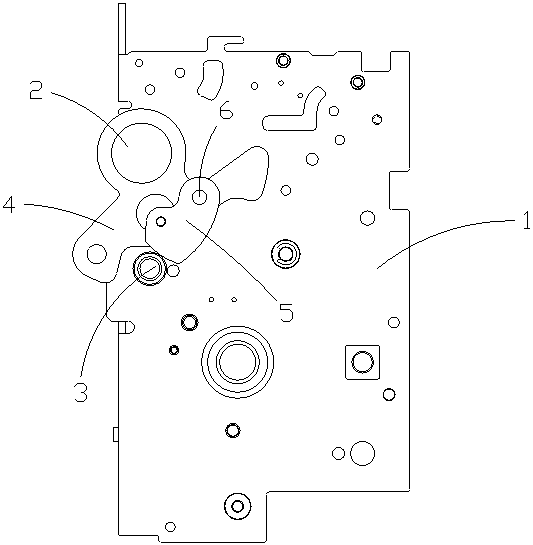

[0019] Such as Figure 1 to Figure 6 The breaker clamp type anti-bounce mechanism shown includes a circuit breaker body 1, a mechanism main shaft 2 and a breaking stop shaft 3 arranged on the circuit breaker body 1, and a cantilever 4 is also arranged on the circuit breaker body 1 , clamping plate 5, clamping plate rotating shaft 6 and tension spring, the cantilever 4 is provided with a first mounting part 41, a second mounting part 42 and a limiting part 43, and the distance between the second mounting part 42 and the limiting part 43 A limited hole 44 is also opened between them, the first installation part 41 of the cantilever 4 is fixedly installed on the mechanism main shaft 2, the clamp rotating shaft 6 is fixedly installed on the second installation part 42 of the cantilever 4, the clamp 5 The rear end of the clamp is rotatably mounted on the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com