Upper sawing panel saw device

A panel saw and up-saw technology, which is applied to the field of up-saw panel saw devices, can solve the problems that the sawing speed is difficult to increase, affect product quality, cannot be used, etc., so as to reduce the requirements of saw blades and increase the output of saw blades. , The effect of prolonging the sharpening cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

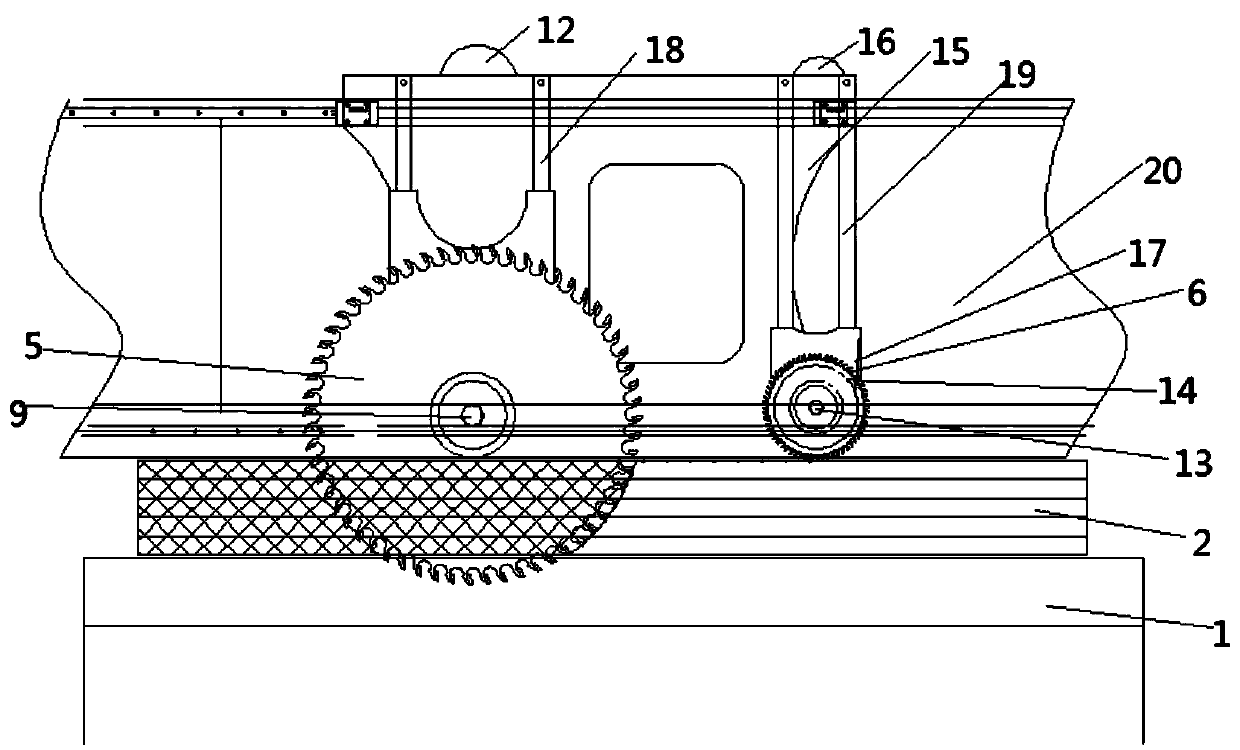

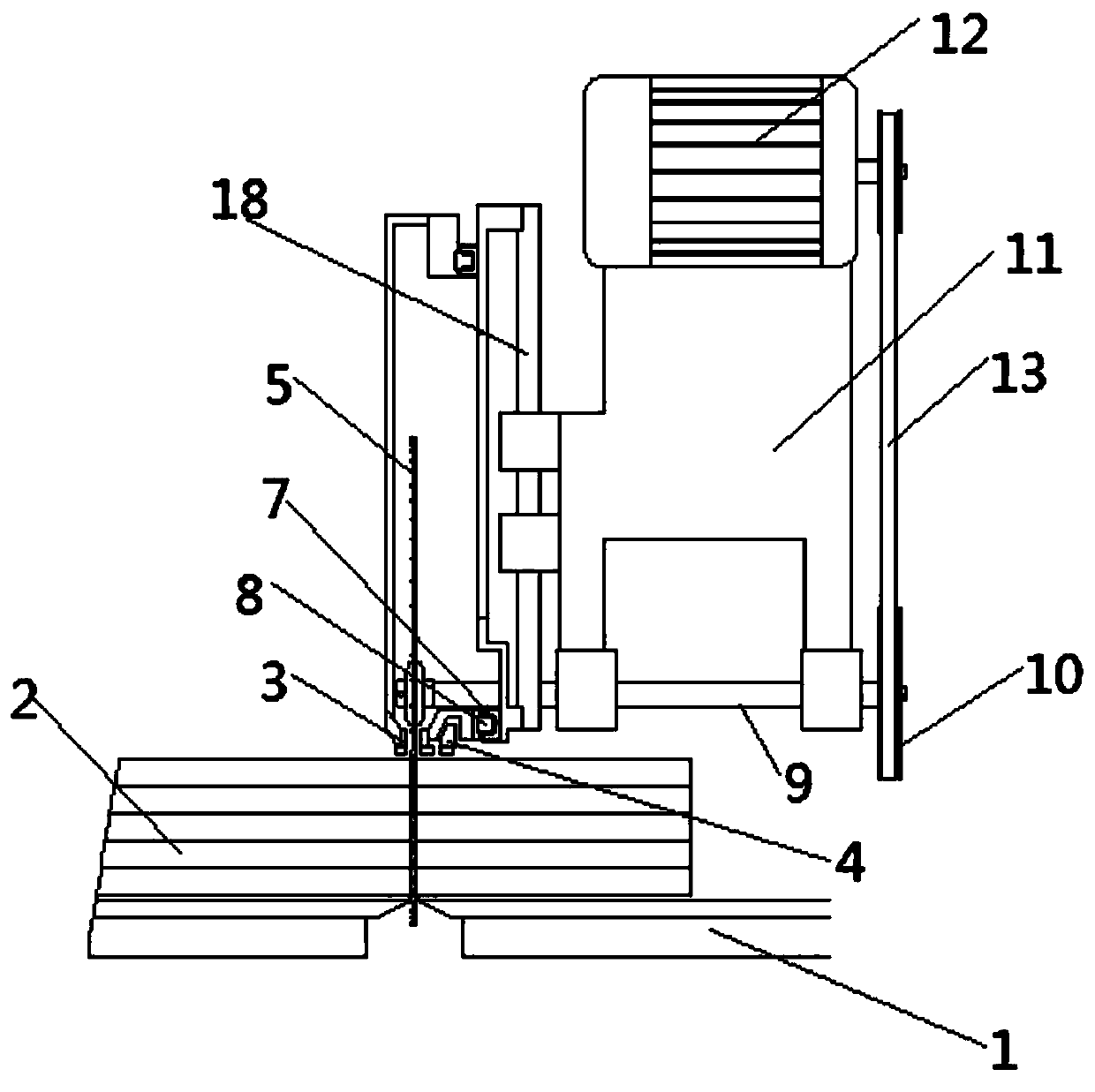

[0020] Such as figure 1 and figure 2 The upper-saw panel saw device shown includes: a table top 1, a sawing workpiece 2 is placed on the upper part of the table 1 (stacked in multiple layers), and the upper surface of the sawing workpiece 2 is pressed by the main pressure beam 3, The rear side of the main pressure beam 3 is provided with an auxiliary pressure beam 4, a main saw blade 5 and a groove saw blade 6 are arranged between the main pressure beam 3, and a linear guide rail 7 in the sawing direction is installed on the rear side, and the straight line The inside of the guide rail 7 is equipped with a slider 8 that moves along the linear guide rail. The main saw blade 5 is connected to the main saw shaft 9 through flange compression, and the main saw shaft 9 is fixed on the main saw mechanism 11. The motor 12 is fixed on the upper part of the mechanism 11, the motor 12 is driven by a belt with the main saw shaft 9, the motor 12 is connected with the main saw wheel 10 th...

Embodiment 2

[0022] Such as figure 1 and figure 2 The upper-saw panel saw device shown includes: a table top 1, a sawing workpiece 2 is placed on the upper part of the table top 1, and the upper surface of the sawing workpiece 2 is pressed by a main pressure beam 3, and the main pressure beam 3 The rear side is provided with an auxiliary pressure beam 4, the main saw blade 5 and the groove saw blade 6 are arranged between the main pressure beams 3, and the linear guide rail 7 in the sawing direction is installed on the rear side, and the linear guide rail 7 is equipped with The slider 8 moving along the linear guide rail, the main saw blade 5 is connected with the main saw wheel 10 through the main saw shaft 9, the main saw shaft 9 is fixed on the main saw mechanism 11, and the upper part of the main saw mechanism 11 is fixed Motor 12, the motor 12 is driven by a belt with the main saw shaft 9, the motor 12 is connected with the main saw runner 10 through a belt 13, and the slot saw blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com