Intelligent door lock mechanical and electrical separation device

An electromechanical separation, intelligent door lock technology, applied in the direction of building locks, non-mechanical transmission-operated locks, buildings, etc., can solve the problems of occupying the lock body, excessive position space, and complex internal structure of the fully automatic lock body. And the effect of simple processing and reasonable setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

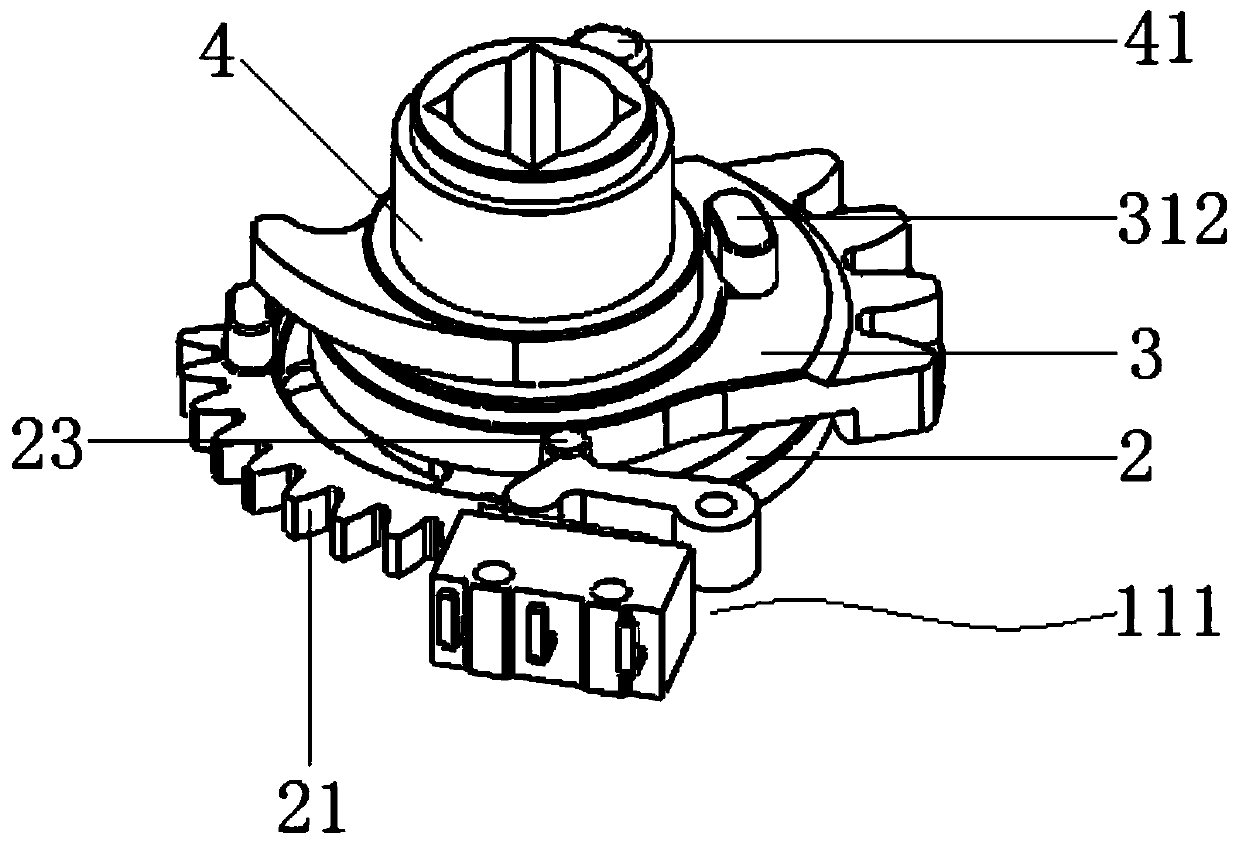

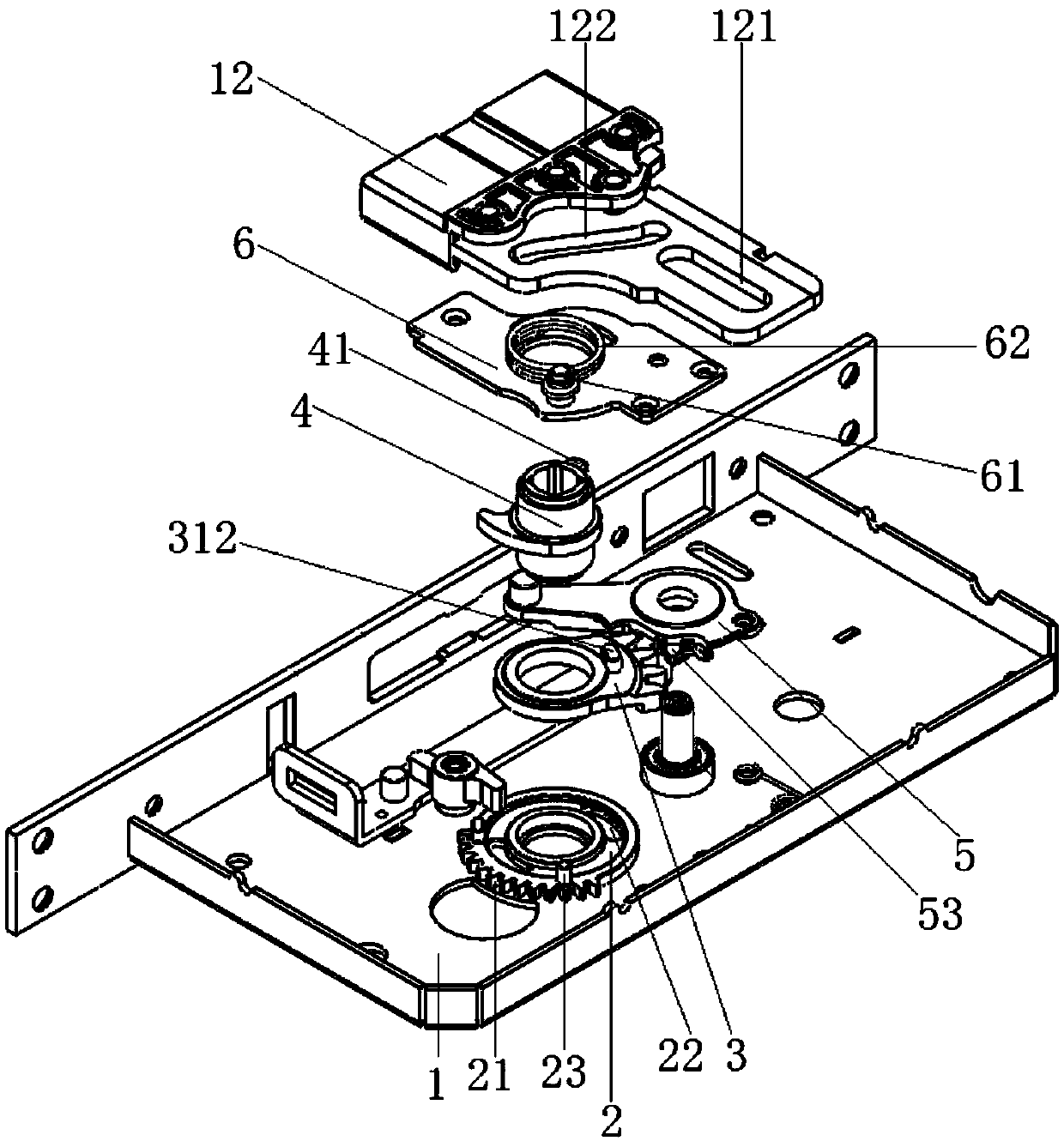

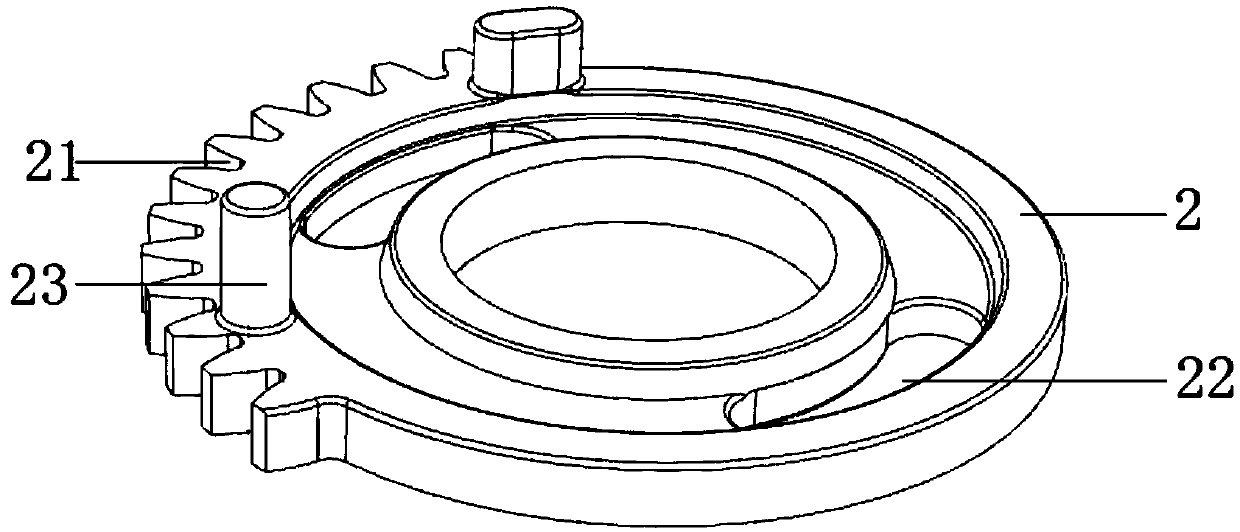

[0037] Embodiment 1 is to use the motor module 11 to electrically unlock the lock. The process is: the motor of the motor module 11 is started, and the output gear of the motor module 11 meshes with the first tooth portion 21 of the first driving part 2, and then drives the first driving part 2 to rotate. , because the first boss 311 snaps into the transmission groove 22 of the first driving member 2, so the first driving member 2 further drives the first transmission member 3 to rotate, and the first transmission member 3 finally drives the second transmission member 5 to rotate, and the second transmission member 5 rotates. The second transmission part 5 then controls the contraction of the main lock tongue 12. When the main lock tongue 12 is retracted in place, the motor of the motor module 11 reverses, and then drives the first boss 311 of the first transmission part 3 to be in the transmission groove of the first drive part 2. 22 at the middle position.

Embodiment 2

[0038] Embodiment 2 is manual mechanical unlocking, and its process is: the second driving part 4 is connected with the conventional lock cylinder, when the lock core drives the second driving part 4 to rotate, the stopper 41 on the outer edge of the second driving part 4 pushes the first transmission The second boss 312 on the top of the part 3 further makes the first transmission part 3 rotate, finally drives the second transmission part 5 to rotate, and then controls the main lock tongue 12 to shrink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com