Method for improving taste of brown rice

A brown rice and taste technology, applied in the field of food processing, can solve the problems of loss of soluble substances, prone to oxidative deterioration, and reduce the quality of brown rice, and achieve the effect of maintaining moisture, preventing the loss of soluble nutrients, and being easy for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

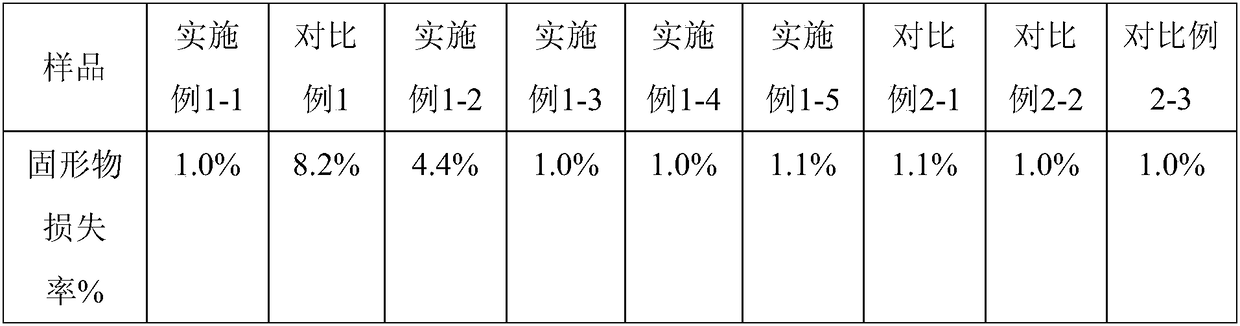

Examples

Embodiment 1-1

[0043] Embodiment 1-1, a method for improving the mouthfeel of brown rice, using brown rice as a raw material, the following steps are carried out successively:

[0044] (1) Cleaning and disinfection:

[0045] Rinse the brown rice with tap water for 2 times so as to remove impurities, and the consumption of tap water for each flushing is 1 weight times of the raw material of brown rice;

[0046] Drain the water (until there is no more dripping water); use ultraviolet rays to irradiate rice grains, and pass through ozone for disinfection for 15 minutes (specifically: put 200g of washed brown rice into a closed container with a volume of 1000mL, and pass through 6mg / L of ozone); Disinfected brown rice.

[0047] (2) Soaking:

[0048] Add aseptic water accounting for 2 times by weight of the brown rice raw material to the brown rice after disinfection treatment, soak at 30° C. for 40 minutes, so that the moisture content in the brown rice is about 26%.

[0049] (3) Dip coating:...

Embodiment 1-2

[0069] The mass concentration of chitosan in the coating liquid of embodiment 1-1 step (3) is changed into 0.5% by 1.5%;

[0070] The rest are identical to Example 1-1.

Embodiment 1-3

[0072] The mass concentration of chitosan in the coating liquid of embodiment 1-1 step (3) is changed into 2.5% by 1.5%;

[0073] The rest are identical to Example 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com