Stocking method for improving stability of blended material component

A technology for mixing and stabilizing ore, applied in the direction of chemical property prediction, etc., can solve the problems of strict site requirements, cumbersome, difficult maintenance, etc., and achieve the effect of improving the stability rate and improving the stability rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] The object of the present invention is to provide a kind of stockpiling method that improves the stability of mixed ore components, which will be realized by the following specific embodiments:

[0022] In the first embodiment of the present invention, the present invention provides a stockpiling method for improving the stability of mixed ore components, comprising the following steps:

[0023] S1: According to the process requirements, formulate a pre-proportion plan for the mixed ore. Under the premise that the total amount of stock A is certain, determine the total number B of minerals participating in the batching and the weight M of each ore, and determine that each ore is in The ratio X in the entire stack;

[0024] S2: According to the on-site production situation, determine the number N of mixing ore batching bins that can be used for batching and the hourly feeding amount corresponding to each batching bin;

[0025] S3: According to the size relationship betw...

Embodiment 1

[0035] In this example, the total amount of stockpiles is about 160,000 tons on a wet basis, and the average flow rate is 1333t·h -1 , each heap takes 120h. See Table 3 for the specific stacking conditions at each stage. And the production and application of mixed ore proportion, mixed ore TFe, SiO 2 Stability rate, and corresponding TFe, SiO of sinter 2 The stability rate was statistically analyzed, and the same stacking process was used, and the plan of increasing the ratio of the rough tower powder with uneven particle size composition was used as a comparative analysis of the effect of the stacking method of the present invention. The results are shown in Table 4.

[0036] In this embodiment, the ratio X ranges from 5% to 15%.

[0037] In this embodiment, m is 3.

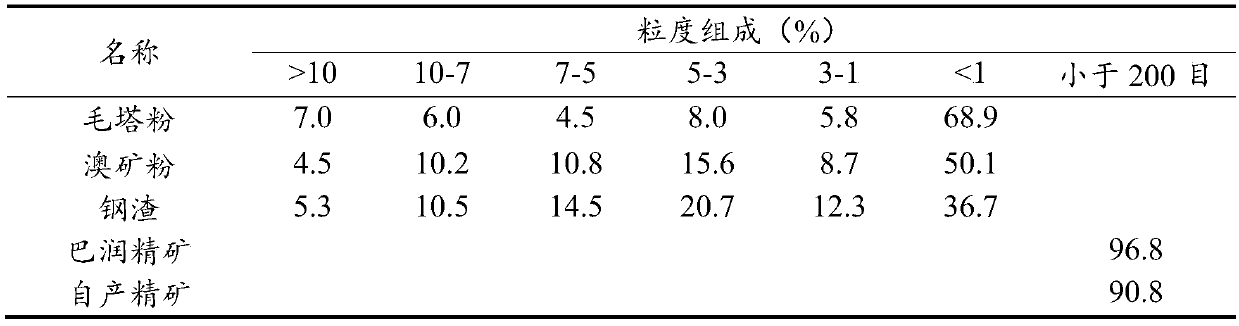

[0038] Table 1 Iron material particle size composition

[0039]

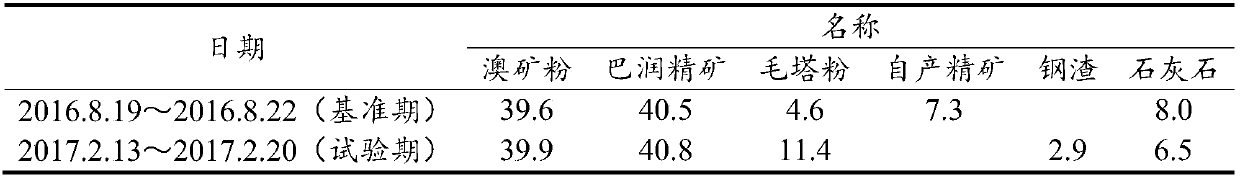

[0040] Table 2: Proportion of mixed ore (%)

[0041]

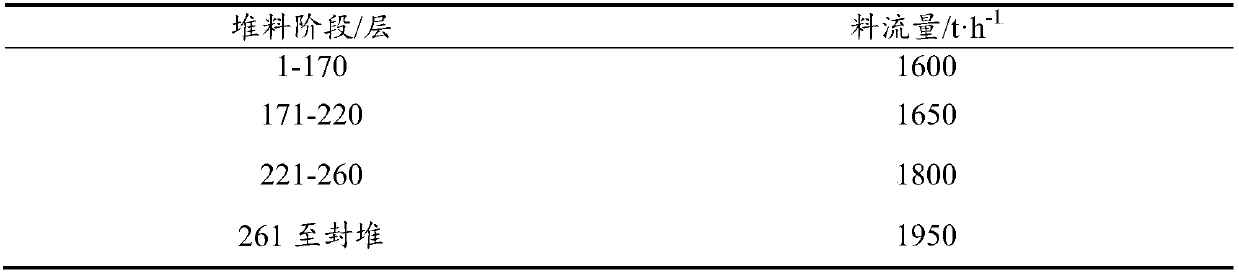

[0042] Table 3: Staged variable flow stacking situation

[0043]

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com