Replacement operation method for inertial wheel of hydraulic switch machine, and special tool thereof

An operation method and technology of special tools are applied in the field of the replacement operation method of the inertia wheel of a hydraulic switch machine and the field of special tools, which can solve the problems of inability to control the spring force of the compression spring, time-consuming and labor-intensive installation, low success probability, etc. Reliable replacement, saving time and cost, improving service quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the present invention more obvious and understandable, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

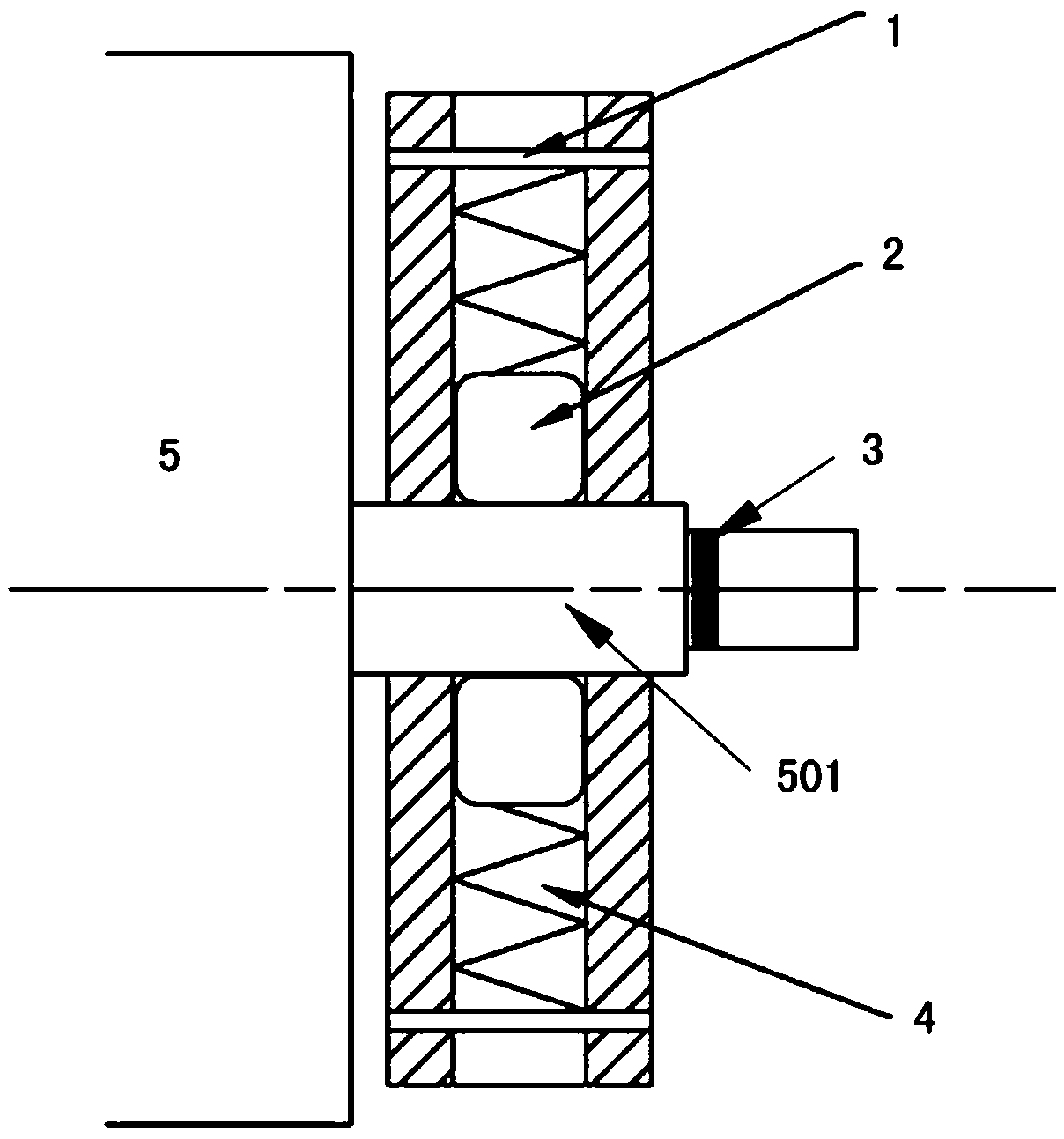

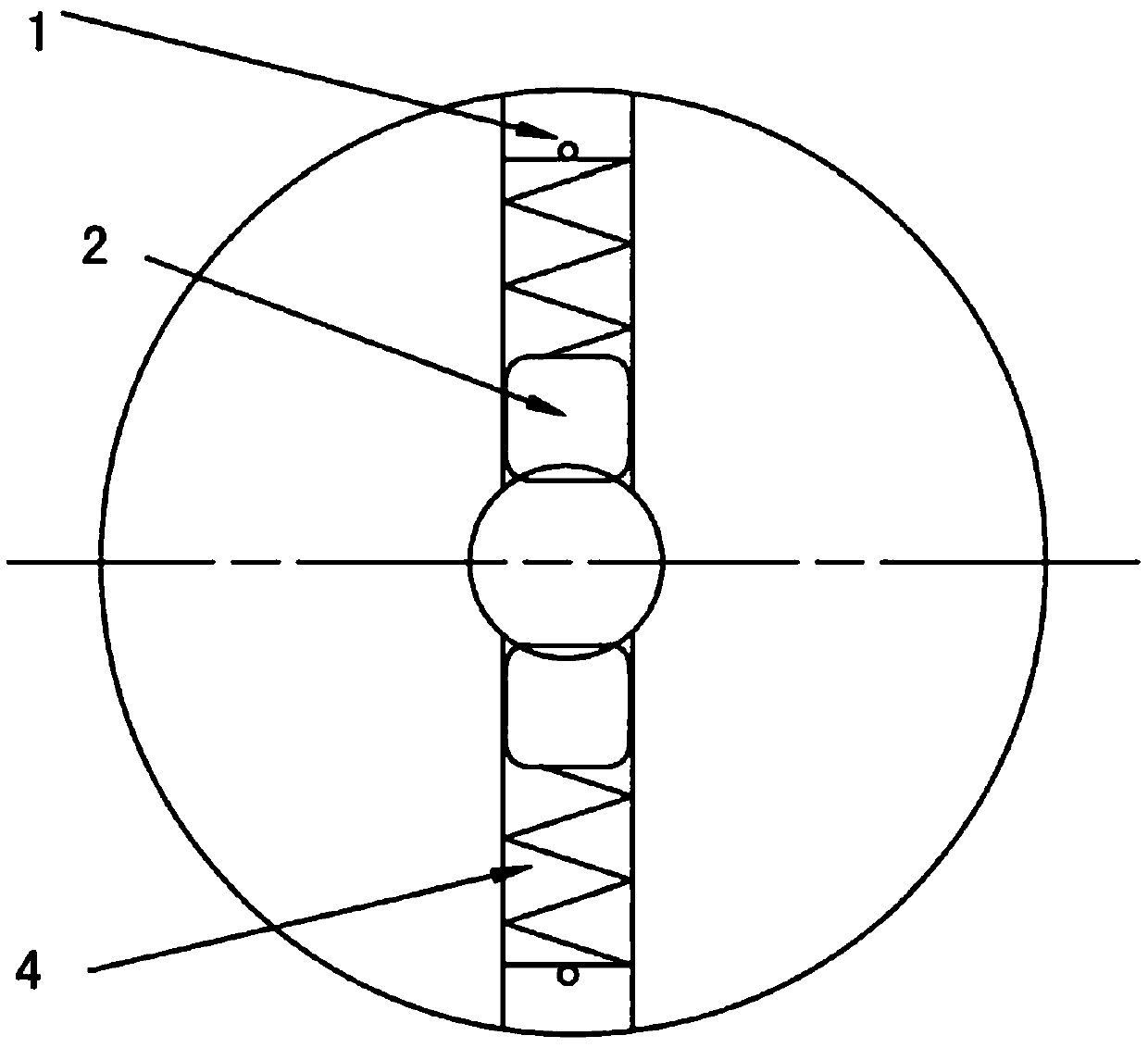

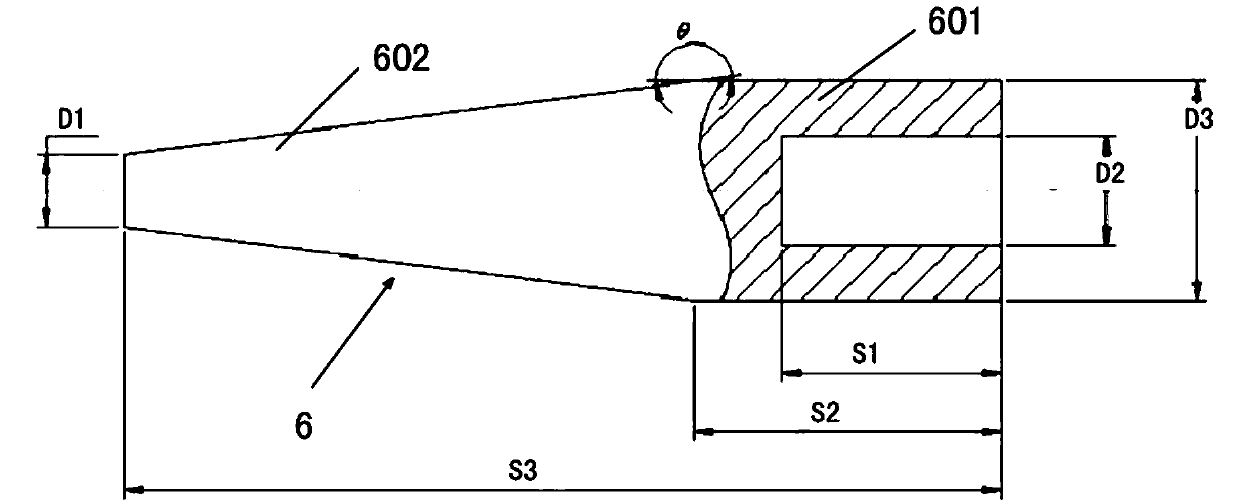

[0042] Such as Figure 3-Figure 6 In combination with the shown, the present invention provides a special tool 6 for disassembling and assembling the inertia wheel. The special tool 6 replaces the screwdriver in the prior art for disassembling and assembling the inertia wheel. The special tool 6 matches the size of the inertia wheel. The special tool 6 for disassembly and assembly can control the compression spring 4 on both sides of the center hole of the inertia wheel at the same time, so that the compression spring 4 can be slowly released during disassembly and can be slowly pressed down during installation; when disassembling the inertia wheel, first move the inertia wheel to the special On the tool 6, the pressure is released slowly through a special tool; when the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com