A method for expanding all-working-condition characteristics of a gas compressor

A technology for compressors and all working conditions, applied in complex mathematical operations and other directions, can solve problems such as lack of component characteristic data, and achieve the effect of high calculation accuracy and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

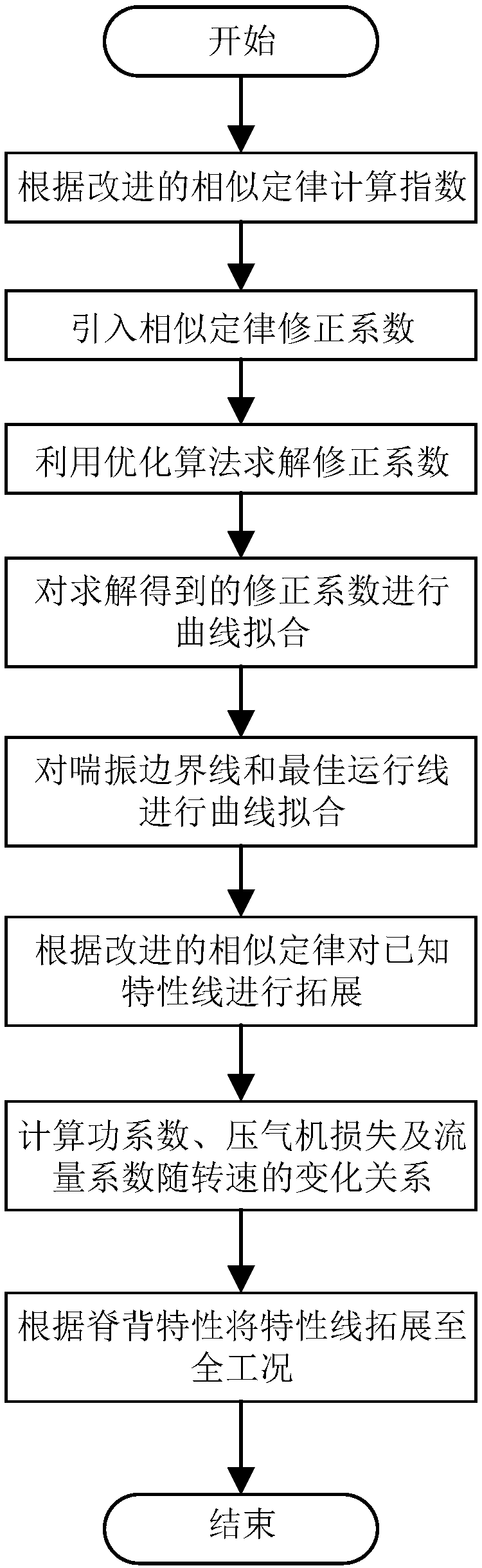

[0052] The present invention is described in more detail below in conjunction with accompanying drawing example:

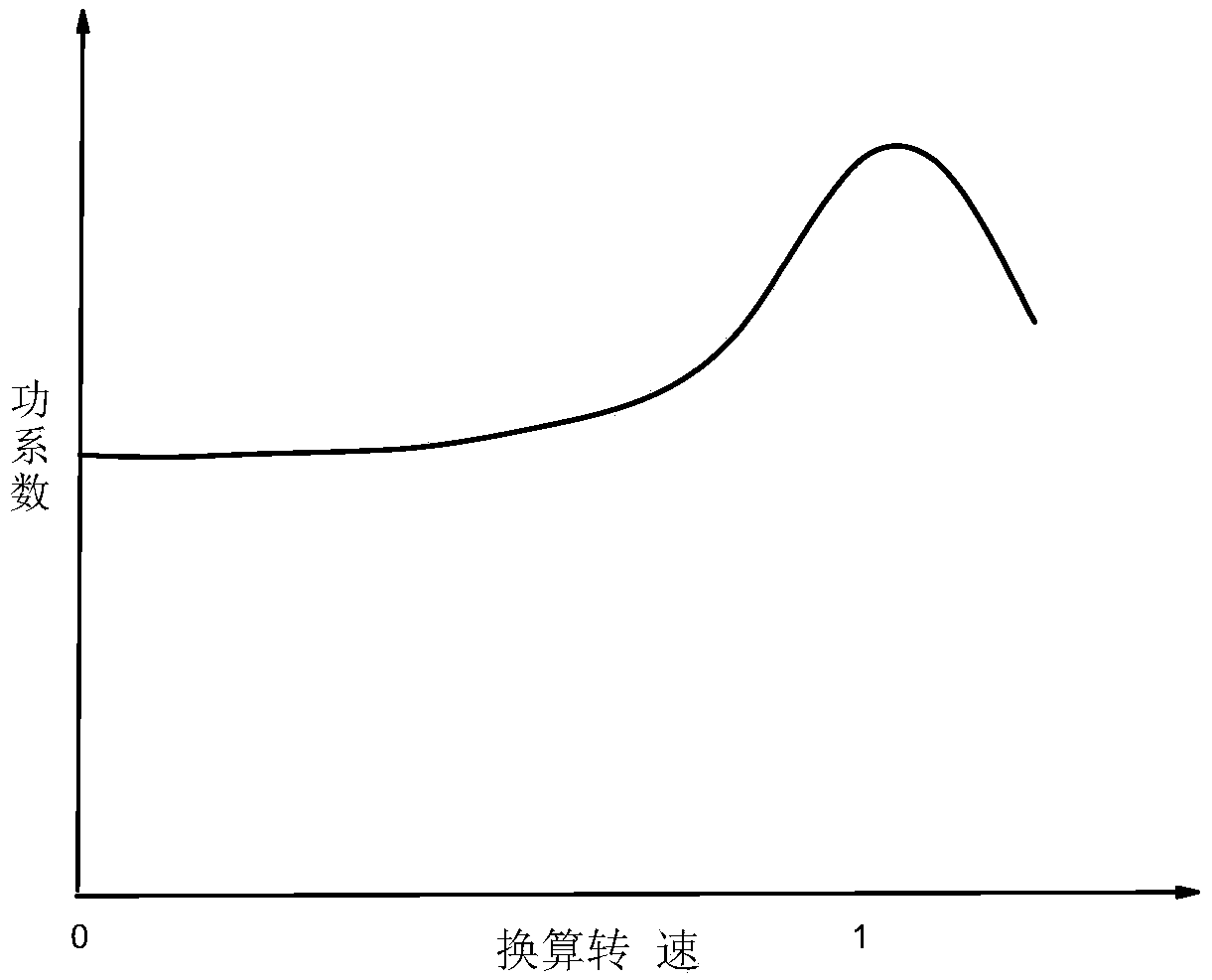

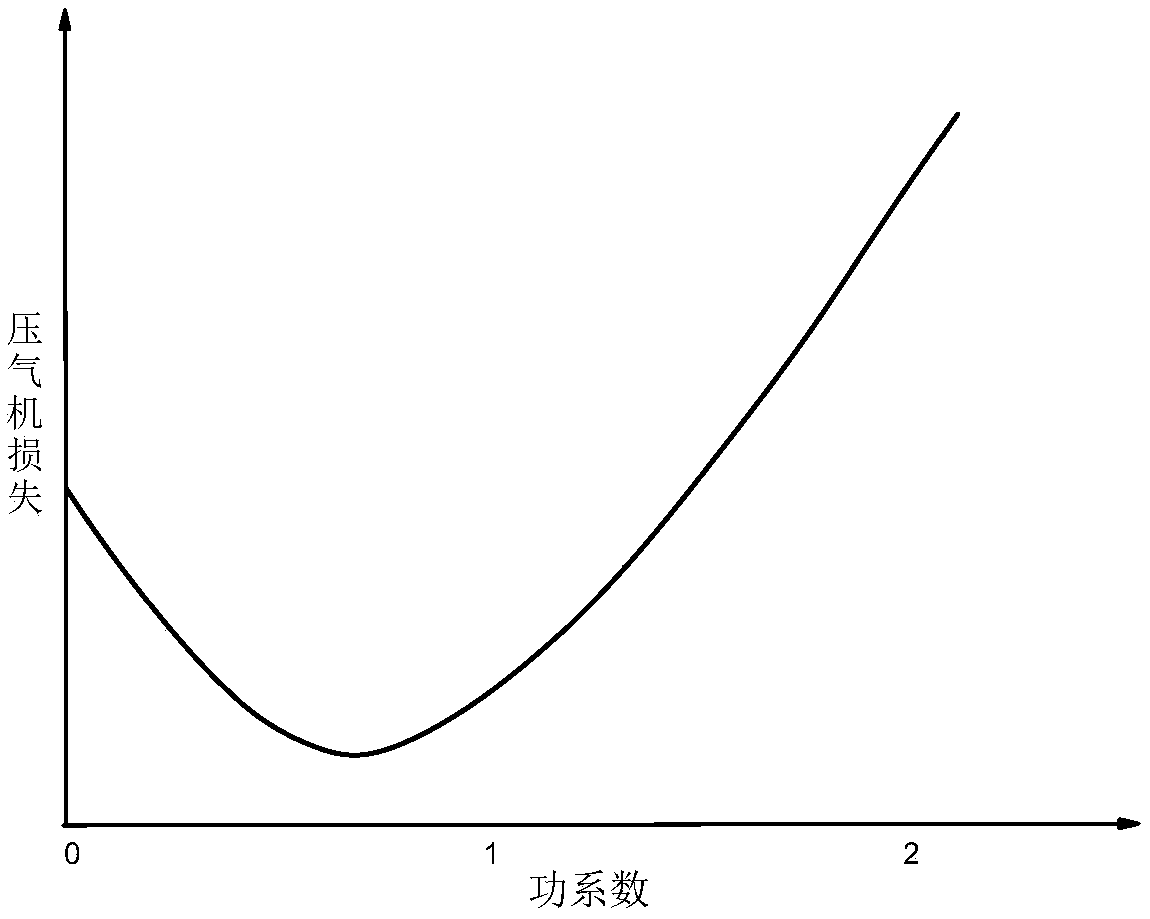

[0053] combine Figure 1-4 , the present invention adopts the following technical scheme: on the basis of the original similarity theorem, with the surge point and the best operating point as the benchmark, calculate the similarity theorem index x between different rotating speeds 1 ,y,x 2 ,z, and then introduce the air density change correction coefficient k 1 、k 2 It is used to correct the air density change caused by air compression at different speeds, k 1 ,k 2 Genetic optimization algorithm can be used for the calculation of , and the minimum value of the error between the actual pressure ratio and the predicted pressure ratio under the same flow rate and the error between the actual efficiency and the predicted efficiency under the same flow rate is the objective function, and then the optimal k 1 ,k 2 solution. will k 1 ,k 2 Carry out curve fitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com