Method for producing N-methyl-para-anisidine

一种茴香胺、甲基的技术,应用在生产烷基化对-茴香胺的液相催化领域,能够解决N-甲基苯胺产率低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

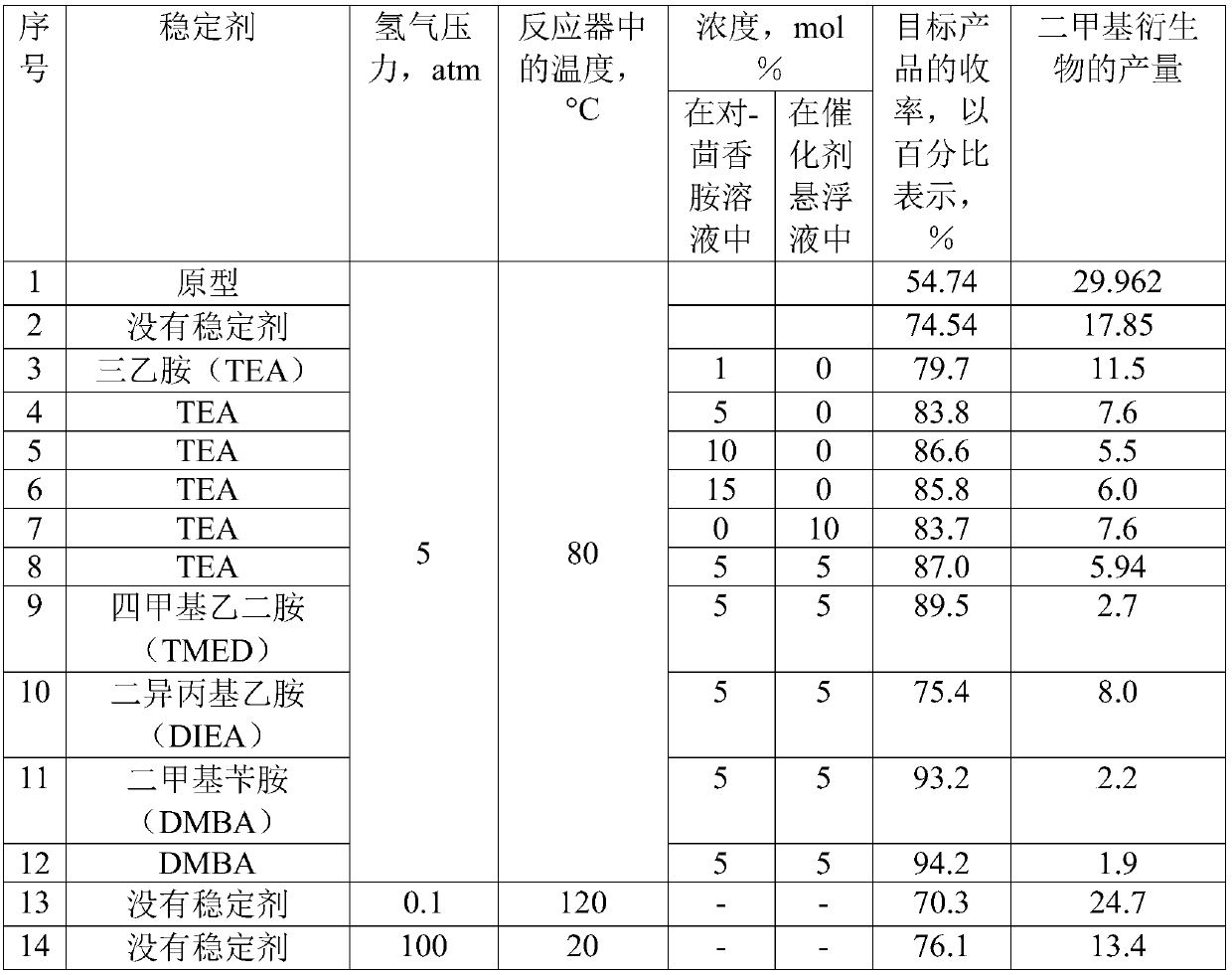

Image

Examples

Embodiment 1

[0036] To the capacity of 400cm 3 Add 5 g of Raney nickel and 100 ml of methanol to the prepared autoclave, which is equivalent to 10 wt% of p-anisidine loading. Close the autoclave loading nozzle with the mixing cap. In one of the burettes, 40.87 grams of formalin containing 29.8 wt% formaldehyde, equivalent to 18.2% of the mass of the reactor's free working volume, was injected, and the other solution was a solution of 50 grams of p-anisidine in 80 milliliters of methanol , corresponding to 59 wt% of the free working volume of the reactor and a concentration of p-anisidine in solution of 44.1 wt% (17 mol%), required a flow rate of feedstock of 1 hour according to calculations to completely empty the burette. Turn on the automatic tracking system for the flow ratio and turn on the pump. After the PTFE tubes are completely filled, the pump is turned off and the tubes are connected to the mixer.

[0037]The autoclave was sealed and purged with nitrogen to remove the air ther...

Embodiment 2

[0043] This example discloses a continuous operation of an autoclave corresponding to that of Example 1, but the autoclave is additionally equipped with nickel and ceramic-metal sintered filters on the riser for sampling and with control at the sampling nozzle Valves for continuous process organization. A filter to prevent catalyst exit from the autoclave was placed about 1 / 2 the height of the autoclave.

[0044] After loading the initial components of Example 1, set the hydrogen pressure to 5 atm on the control valve, then proceed as in Example 1, but after emptying the burette, the process does not stop, instead they inject the pair again - Anisidine and formaldehyde solution, repeat this periodically as needed. The autoclave was gradually filled.

[0045] After about 1.5 hours, the first drops of catalyst appeared on the discharge nozzle of the control valve, and like all subsequent ones, they were sent to the receiving tank. After 75 hours of continuous operation, the p...

Embodiment 3

[0049] In a pipe with a diameter of 25 mm and a height of 500 mm made of stainless steel Х18Н10Т, a mixer and fittings for hydrogen supply as in Example 2, upper control valve, jacket heated with hot water and thermocouple housings are installed below Tube, 250 ml 3-5 mm size Raney nickel catalyst. The mixer as in Example 2 was connected to the fluoroplastic tubing to the burette-pump system and the hydrogen fitting was connected to the hydrogen gas line.

[0050] With the temperature set on the thermostat at +80°C and the pressure on the control valve at 5 atm, open the thermostat. When the set temperature was reached, the pump and hydrogen supply were turned on as in Example 2. Total consumption of liquid components is 1h -1 , hydrogen is 0.3min -1 . The liquid reaction product was collected at the collection point. 75 hours of continuous work.

[0051] After distillation of the catalyst, 6068.49 g of products are obtained: N-methyl-p-anisidine - 80.2%, N,N-dimethyl-p-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com