Evaporative tank rinsing agent for vehicles, and preparation method thereof

A technology of rinse agent and evaporation box, applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of complex preparation process, residue, high cost, etc., and achieve improved comfort, quick removal, and strong Effect of the rinse function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

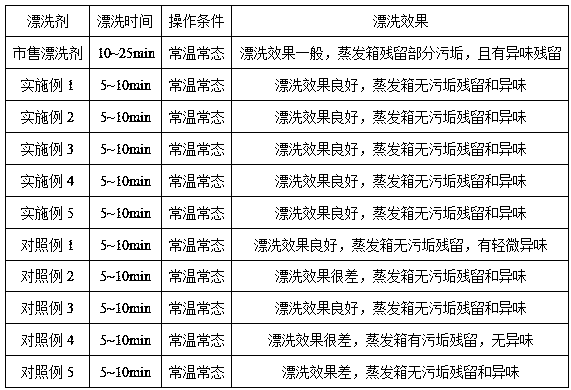

Examples

preparation example Construction

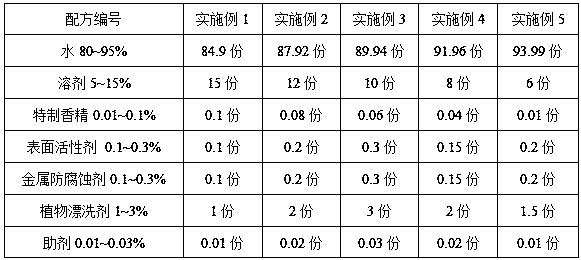

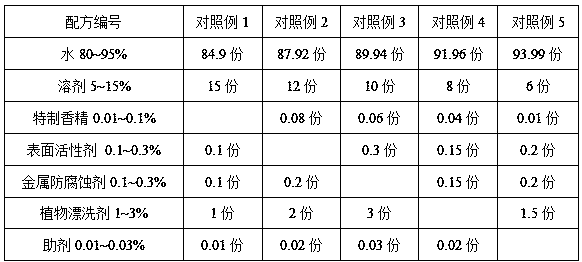

[0046] A kind of preparation method of evaporating box rinse agent for vehicle of the present invention comprises the following steps:

[0047] (a) Add 0.1~0.3% metal anti-corrosion agent to the reaction kettle, raise the temperature to 60~80°C, add 0.01~0.03% additive, slowly add boiling water 80~95%, 1000~2000r / min, stir for 20~ 30 minutes;

[0048] (b) Add solvent 5~15%, special flavor 0.01~0.1%, surfactant 0.1~0.3% in another reaction kettle, 1000~2000r / min, stir for 5~10 minutes;

[0049] (c) Lower the temperature of the solution in step (a) to normal temperature, pour the solution in step (b) into the solution in step (a), stir at a low speed at normal temperature and at a speed of 100~300 r / min, and Add 1-3% plant rinse agent according to the weight percentage. After adding the materials, gradually increase the stirring speed to 1000-2000 r / min, and continue for 10-25 min until the stirring is uniform and a homogeneous solution is formed;

[0050] (d) Stop stirring, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com