Motor cable locating device

A technology for positioning devices and cables, applied in the directions of electromechanical devices, casings/covers/supports, electrical components, etc., can solve the problems of belt wear, difficult cables, and short working time, so as to reduce damage, Improve the level of protection and avoid interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in connection with the drawings and embodiments.

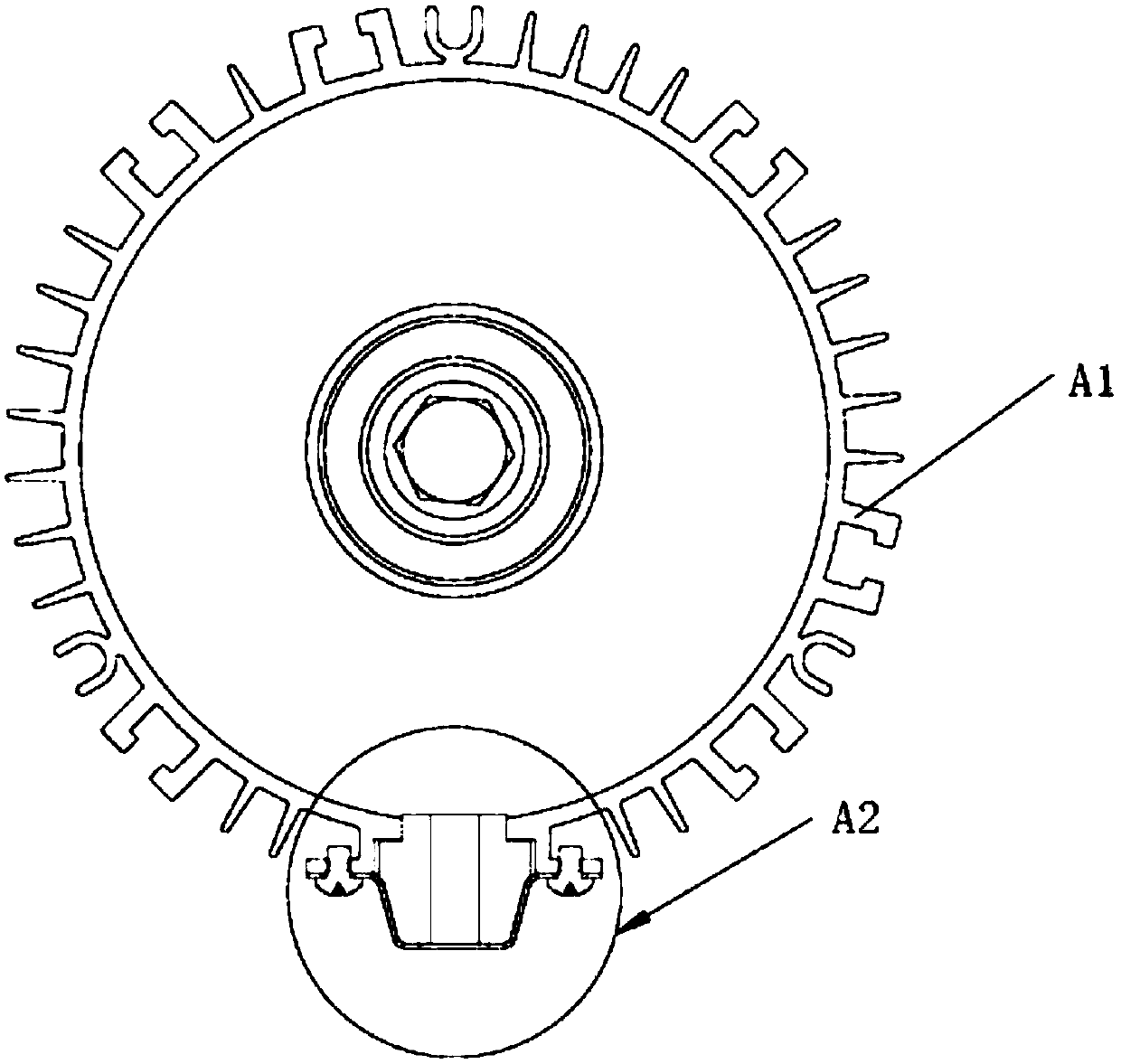

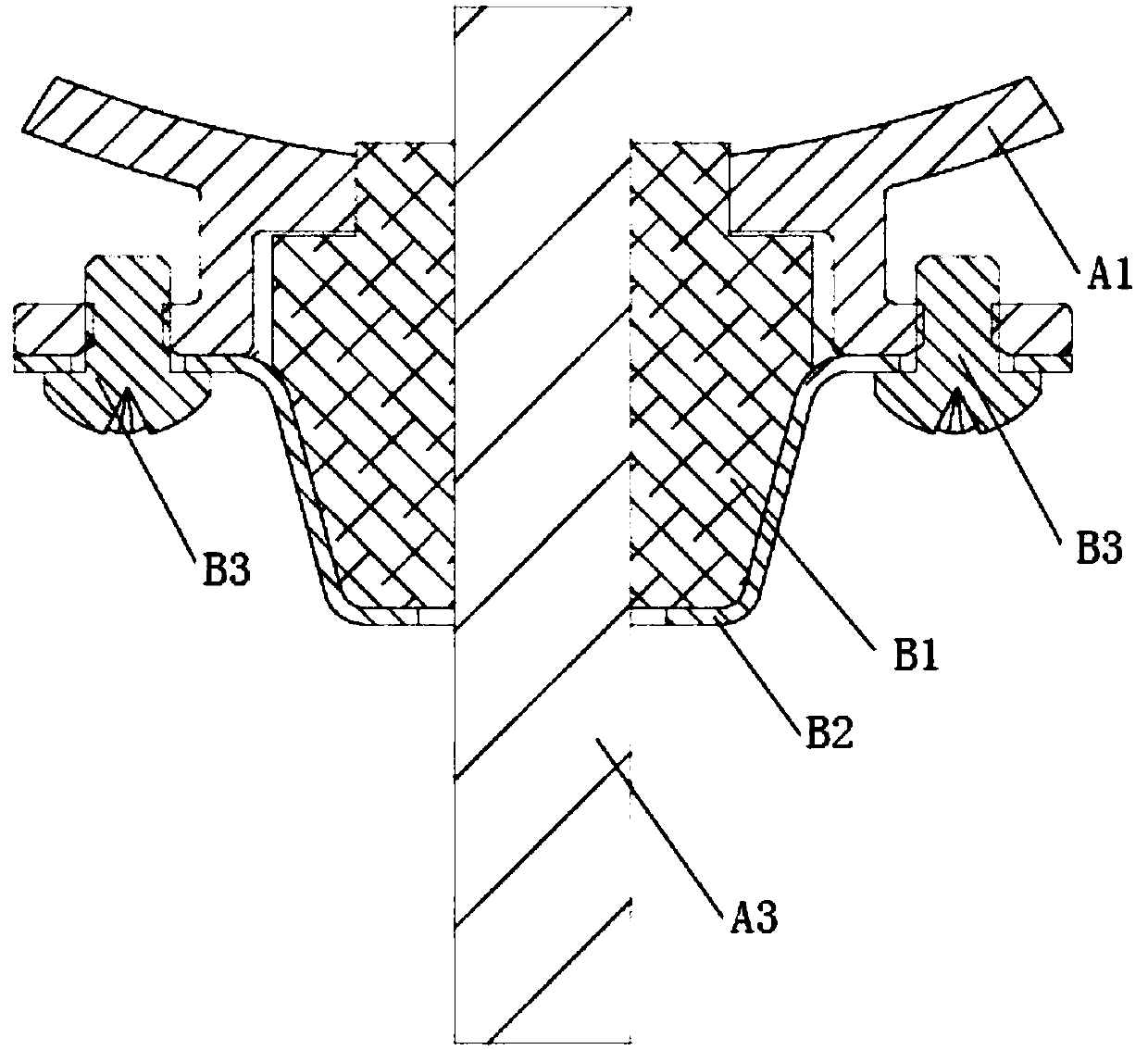

[0017] Such as Figure 1-Figure 2 As shown, the motor cable positioning device, the motor cable positioning device A2 has a cable groove arranged on the motor cover A1 to allow the cable A3 to pass through, and is located in the motor cover A1 and hooped sequentially from the inside to the outside. The leakage plugging piece B1 on the cable A3 and the cover body B2, the cover body B2 is squeezed tightly on the outer wall of the leakage plugging piece B1 and the motor housing A1 is firmly connected.

[0018] The back wall of the leak-stopping piece B1 can be securely embedded in the cable groove, and the leak-stopping piece B1 and the edge walls of the cable A3 are closed and arranged. Thus, by assembling the back wall of the leak-stopping sheet B1 so that it can be firmly embedded in the cable groove, the interaction between the cable A3 and the cable groove is larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com