Cast-in-place concrete finishing shoe

A technology for concrete and bare shoes, applied in footwear, soles, clothing and other directions, can solve the problems of small contact area, easy to leave footprints, unfavorable protection of finished products on the concrete surface, etc., to achieve simple and convenient operation, low cost, and ensure construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

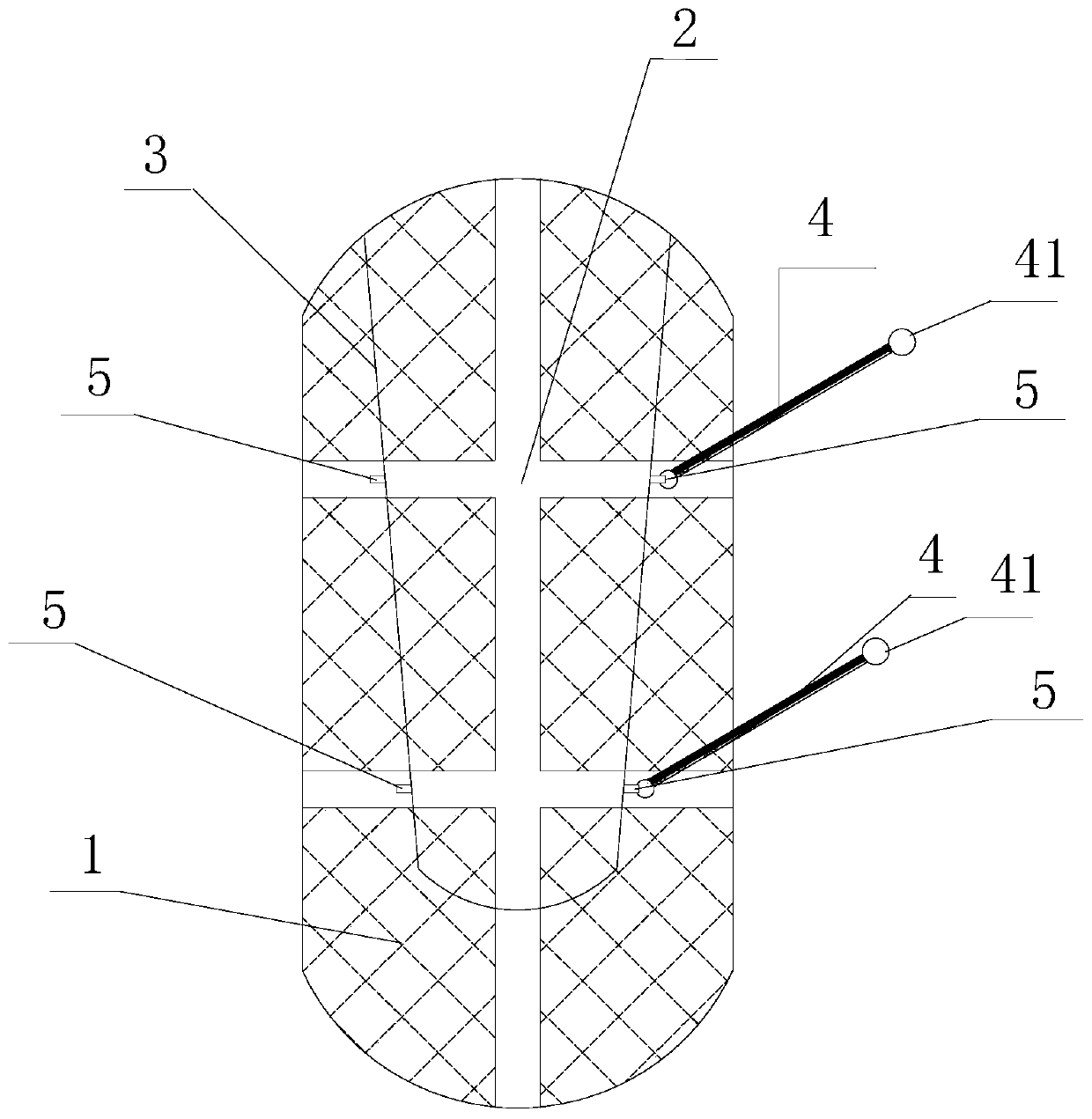

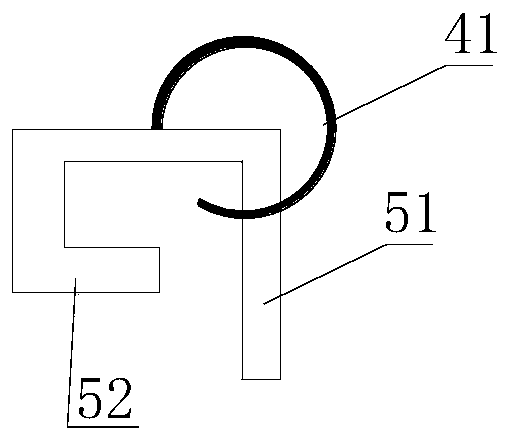

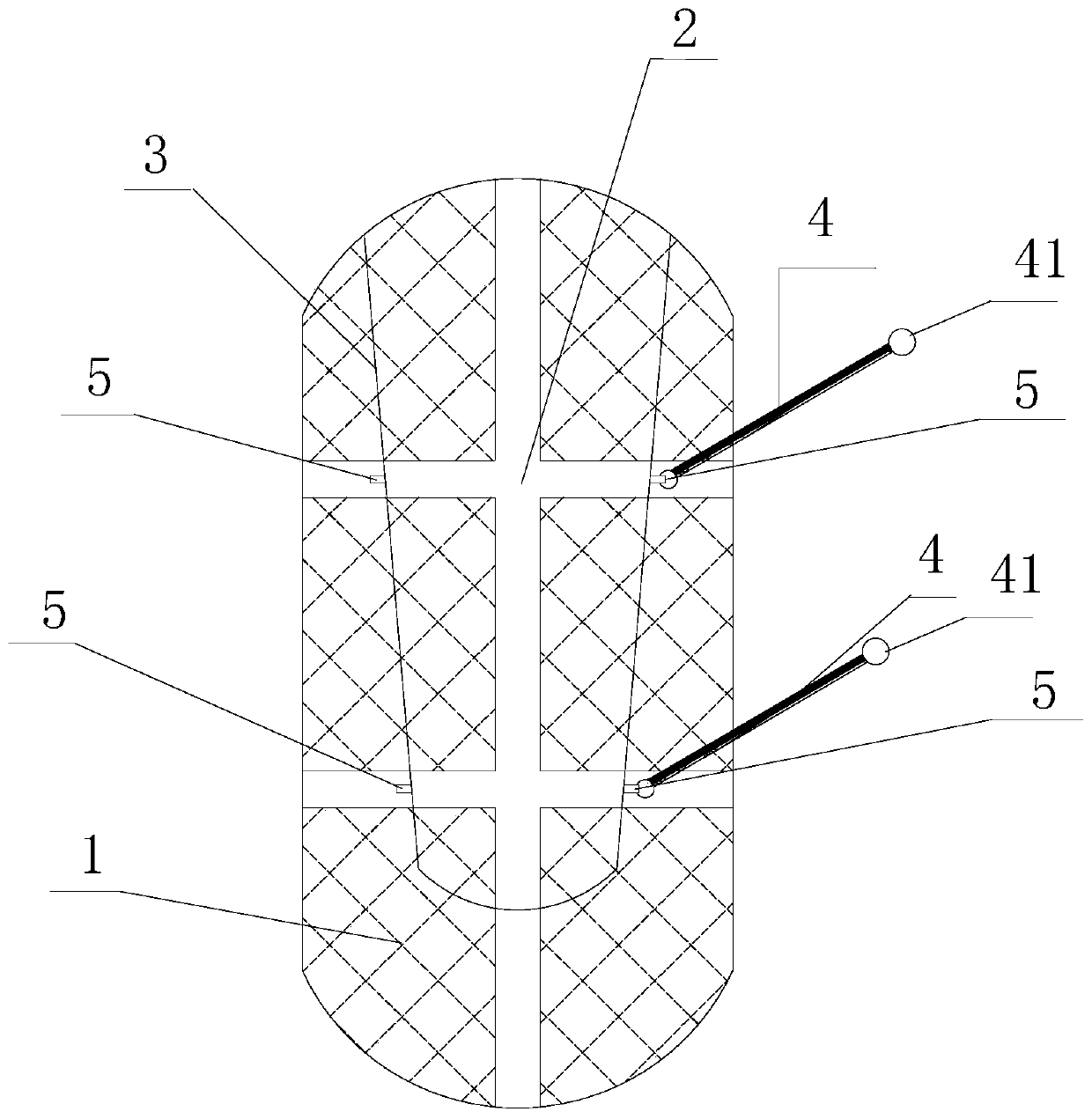

[0019] Such as figure 1 with figure 2 As shown, this embodiment relates to a cast-in-place concrete light-receiving shoe, which is used for secondary light-receiving after the initial setting of concrete pouring and before final setting. Specifically, the light-receiving shoe includes a bottom plate 1, an arc-shaped cofferdam 3 and Bandage 4; the base plate 1 is roughly oval, and the upper surface of the base plate 1 is grid-shaped, wherein the length of the base plate 1 is 300-500mm (such as 300mm, 400mm, 450mm or 500mm, etc.), and the width is 200mm. -400mm (such as 200mm, 300mm, 350mm or 400mm, etc.), thereby increasing the pressure area of the concrete surface, and will not make it difficult for workers to operate because the area of the bottom plate 1 is too large; the arc cofferdam 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com