Isothermal and uniform flowing-velocity double water-cooled horizontal reactor

A horizontal reactor and constant flow rate technology, which is applied to chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inapplicable isothermal and constant flow rates, etc., to reduce the cold wall effect, eliminate temperature difference stress, reduce The effect of temperature differential stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

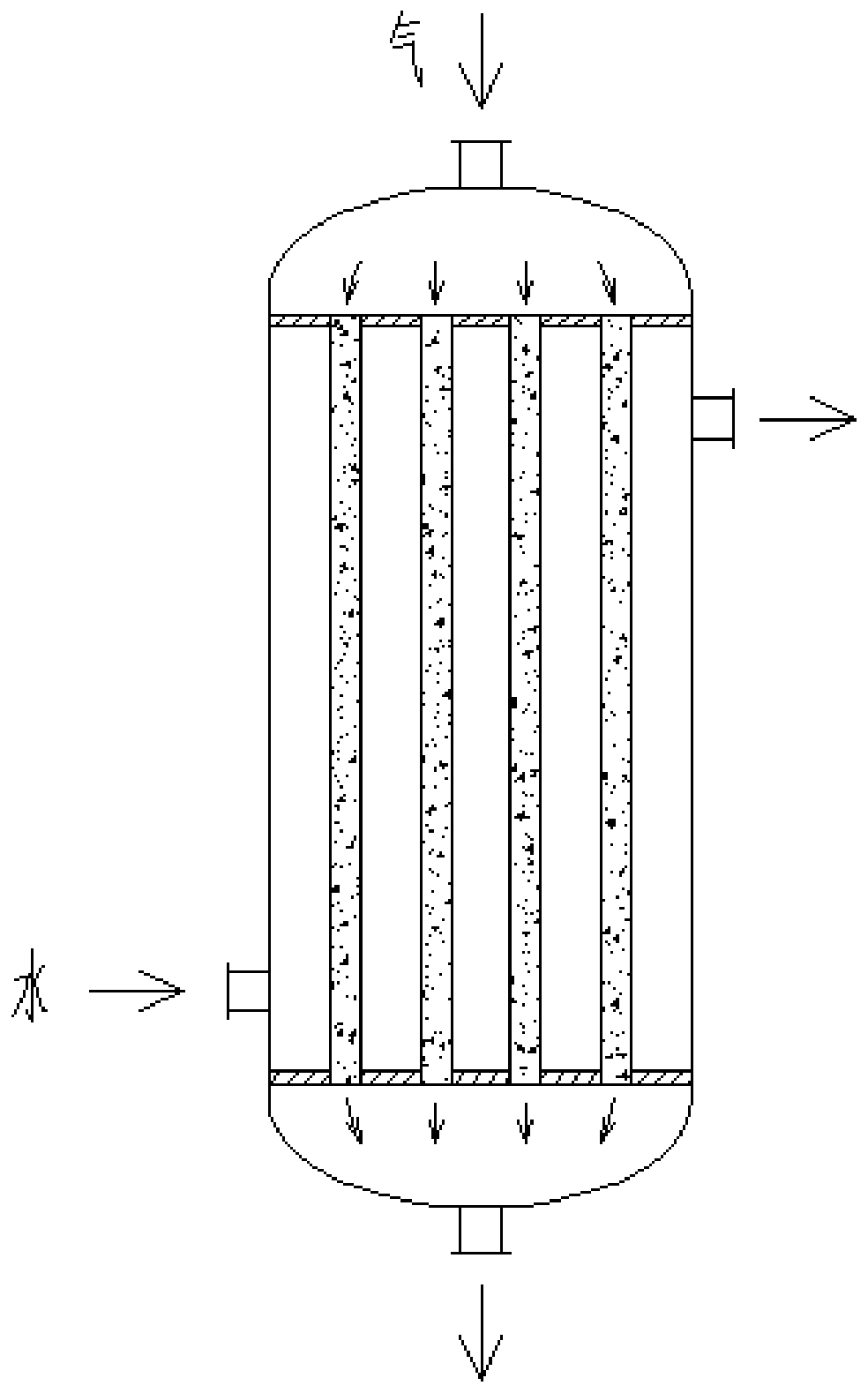

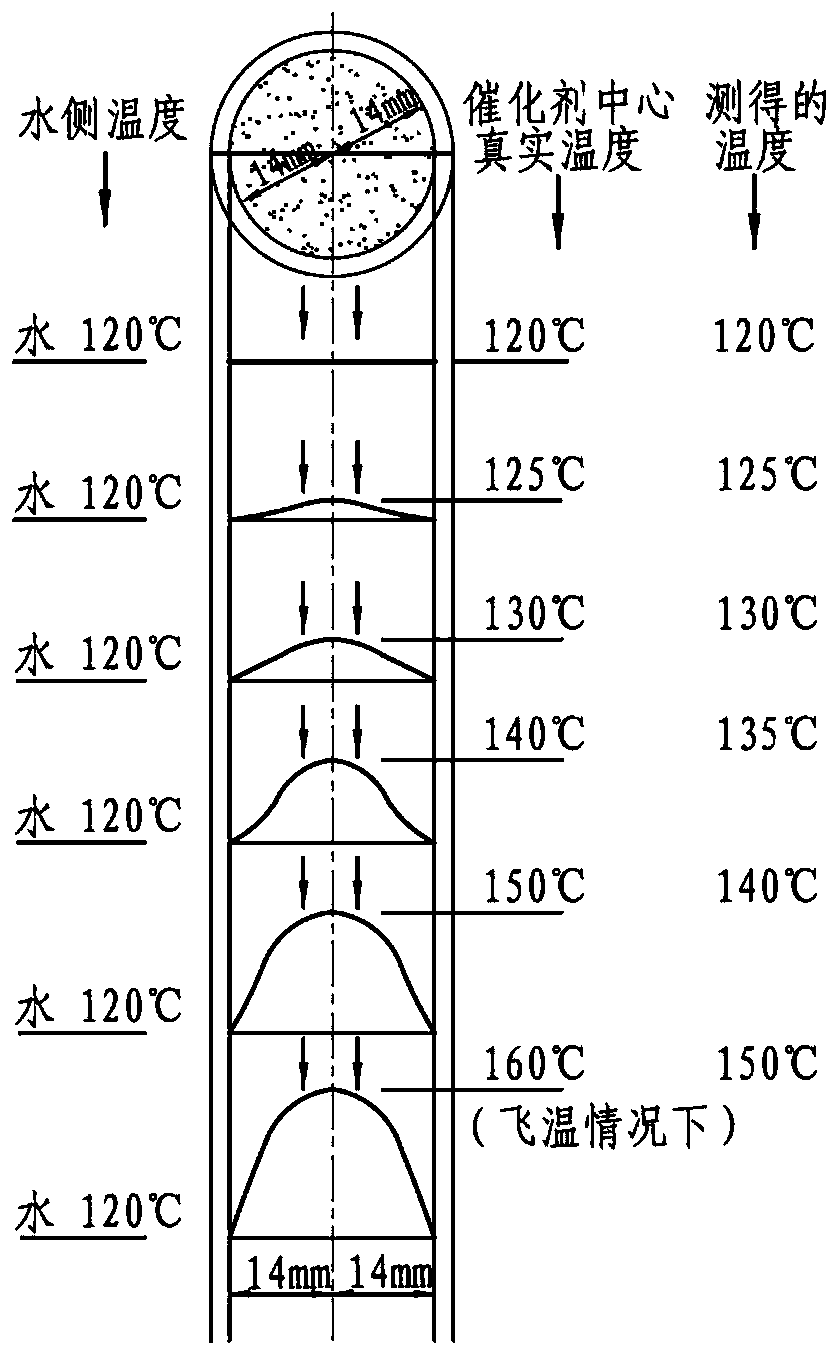

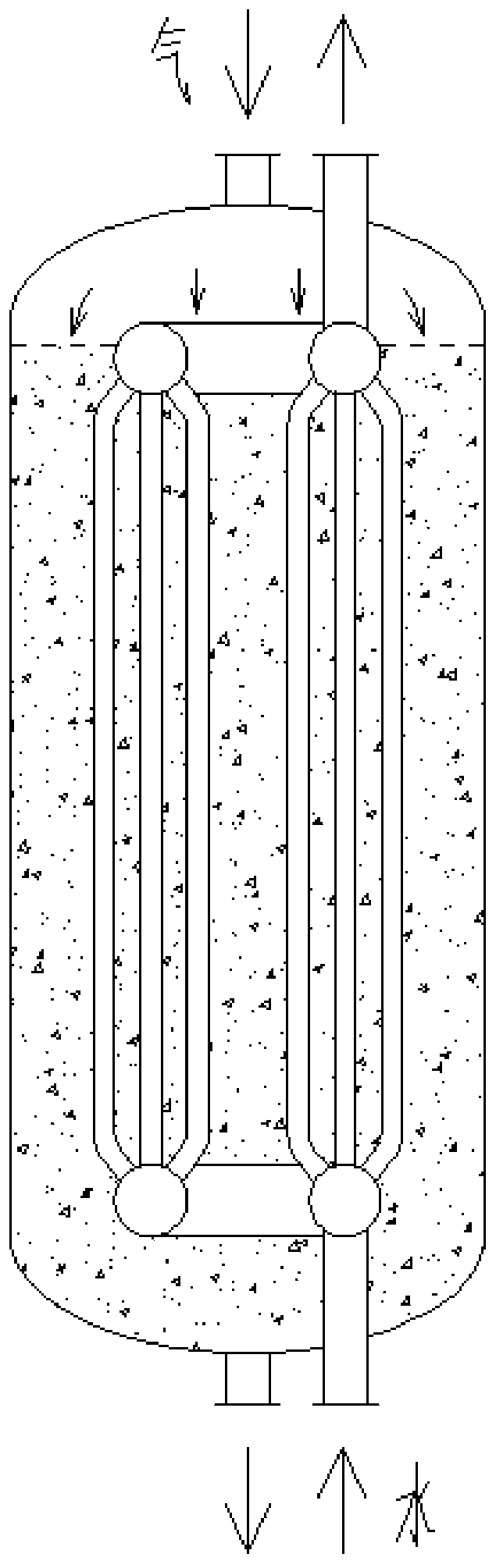

[0049] Such as Figure 5-Figure 7 As shown, a double-water-cooled horizontal reactor with isothermal and constant flow rate includes a cylinder body 9, a left head 1a and a right head 1b respectively arranged on both sides of the cylinder body 9, and the left and right ends of the cylinder body 9 respectively. The left end outer tube plate 3a and the right end outer tube plate 3b, the left end inner tube plate 6a and the right end inner tube plate 6b respectively arranged inside the cylinder body 9, the catalyst frame installed between the left end inner tube plate 6a and the right end inner tube plate 6b 21. A number of sleeve-type water-cooled heat exchange tube groups are arranged in a number of manholes 19 in the upper and lower parts of the cylinder body 9; the left end tube box is formed between the left end inner tube plate 6a and the left end outer tube plate, and the right end The right end tube box is formed between the inner tube plate 6b and the right end outer tub...

Embodiment 2

[0064] On the basis of the double-water-cooled horizontal reactor with constant temperature and constant flow rate in Example 1, cooling water outlets 12 are provided at the bottoms of the left and right end pipe boxes respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com