Pipe arranging mechanism with ball reciprocating lead screw for hydraulic operation machine

A working machine and ball technology, applied in the direction of drill pipe, casing, gas discharge, etc., can solve the problems of unstable screw and steering slider, high failure rate of equipment, weak strength, etc., achieve small driving torque and improve operation Depth, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

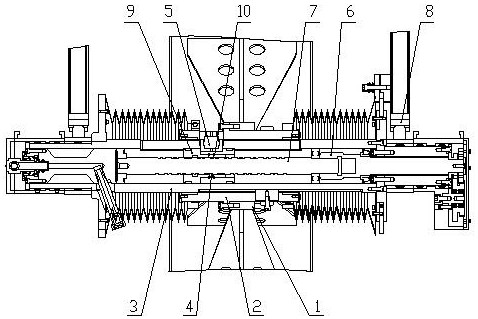

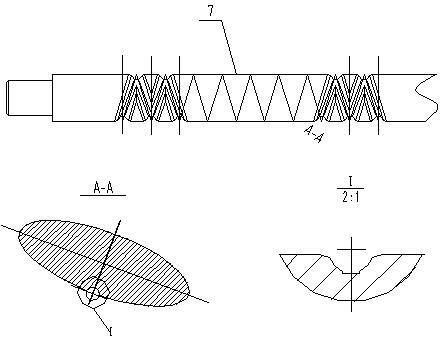

[0022] As shown in the figure, the pipe arrangement mechanism with ball reciprocating screw for hydraulic working machine includes drum hub 1, stroke slider 2, support shaft 3, ball 4, rolling slider 5, transmission shaft 6, and reciprocating screw 7. Support arm 8, slider sleeve 9 and limit steel wire 10, said slider sleeve 9 slides left and right on the reciprocating screw 7, one end of slider sleeve 9 is provided with a through hole 11 and two reversing The groove 12, the through hole 11 and the two reversing grooves 12 are all placed with balls 4, wherein the balls 4 in the reversing groove 12 are symmetrically placed on the outermost end of the reversing groove 12, and pass through the slider cover 9. The limit steel wire 10 in the two grooves of the two grooves is used to limit the position; the reciprocating screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com