Workbench for stove pipeline machining

A workbench and pipeline technology, applied to workbenches, manufacturing tools, etc., can solve problems such as small application range, lower processing quality, deviation, etc., and achieve uniform and stable push and pull force, improve stability, and direct and effective force transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

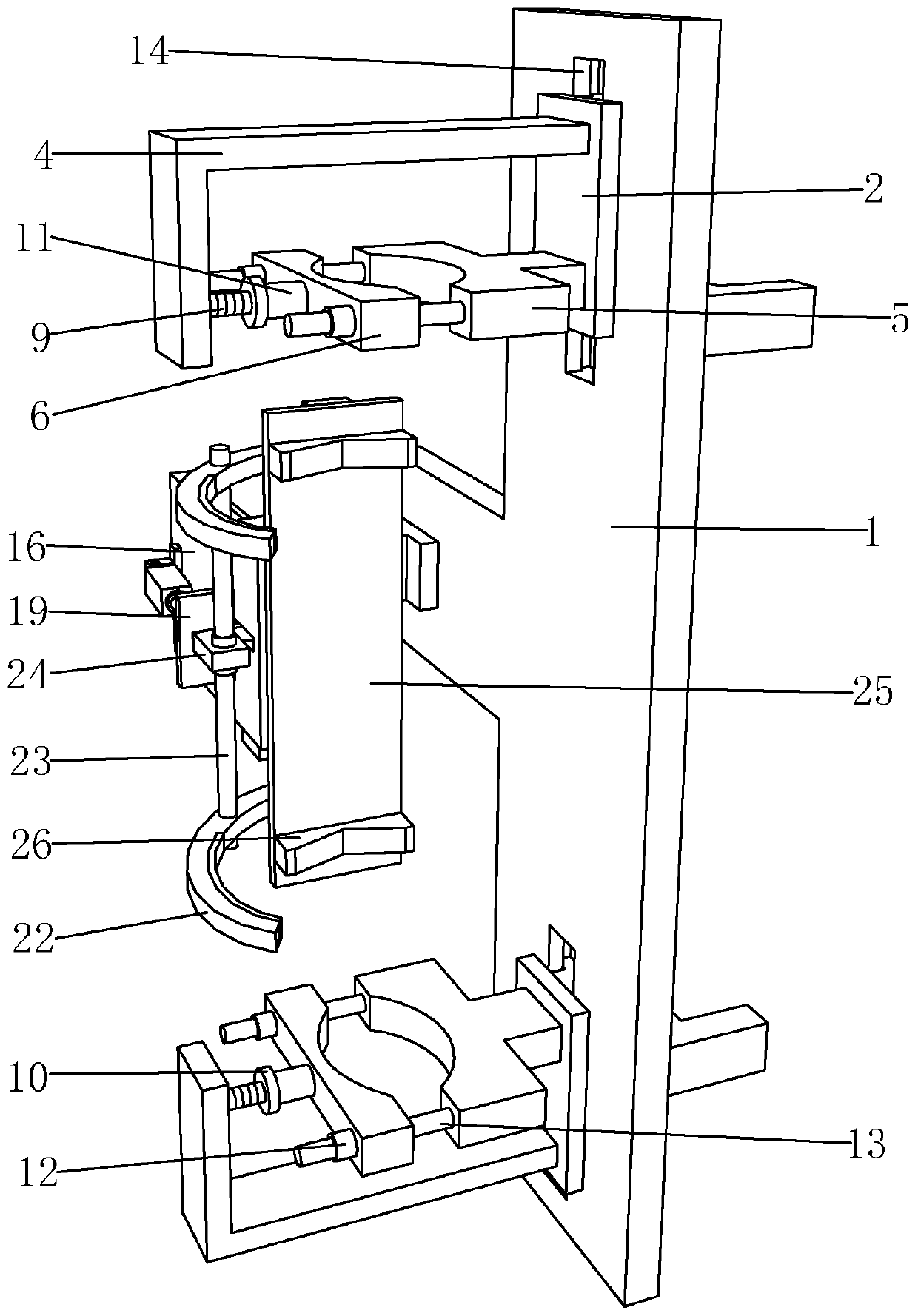

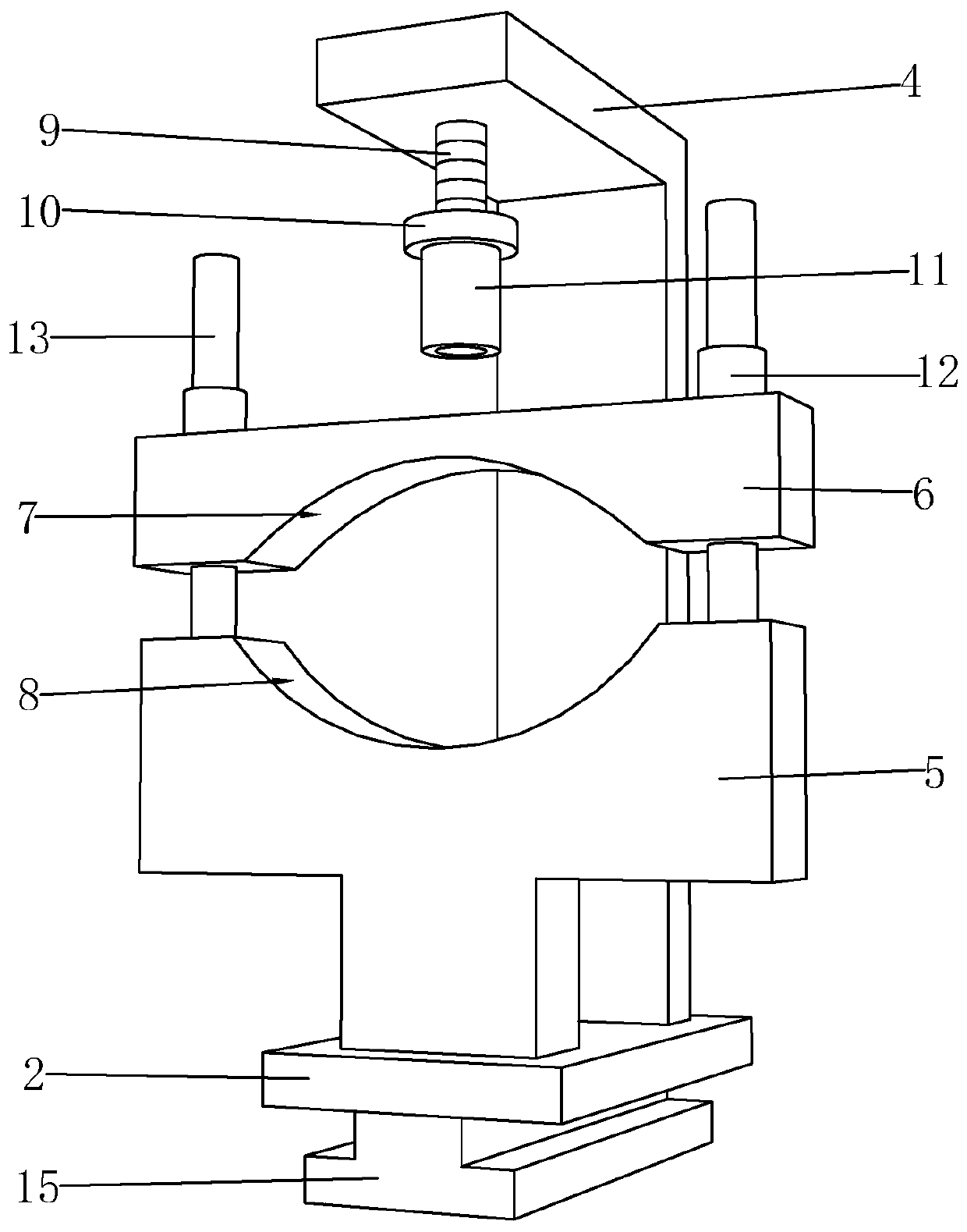

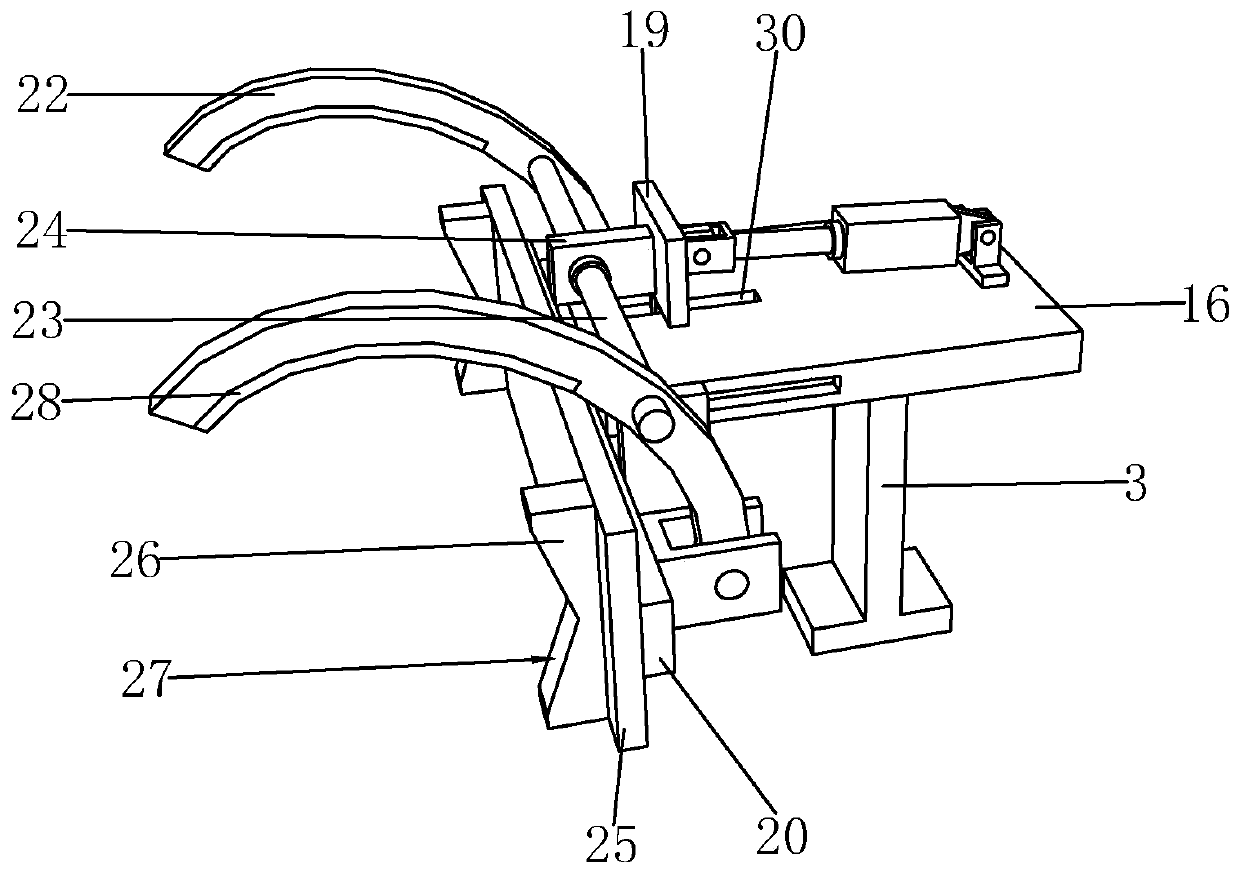

[0024] like Figure 1 to Figure 5 As shown in the figure, it is a workbench for cooking stove pipes according to the present invention, which includes a support frame 1, on which a bottom plate 2 and a fixed bracket 3 are respectively arranged, the bottom plates 2 are symmetrically distributed, and the fixed brackets 3 are located between the bottom plates 2, The bottom plate 2 is respectively provided with an L-shaped fixing plate 4 and a bracket, and the bracket 5 is longitudinally slidably connected with a pressure plate 6, and the bottom surface of the pressure plate 6 is provided with an arc-shaped slot 7, so as to be suitable for cooker pipes of different diameters. Increase the contact area with the outer wall of the pipe and improve the compaction effect. The bracket 5 is provided with an arc-shaped shelf groove 8, to adapt to different diameters of cooking utensil pipes, increase the contact area with the outer wall of the pipe, improve the supporting effect, and limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com