Apple peeling and slicing all-in-one machine

An all-in-one machine and slicing technology, which is applied in the peeling of vegetables or fruits, fruit pitting devices, metal processing, etc., can solve the problems of low production efficiency, unfavorable automatic connection, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

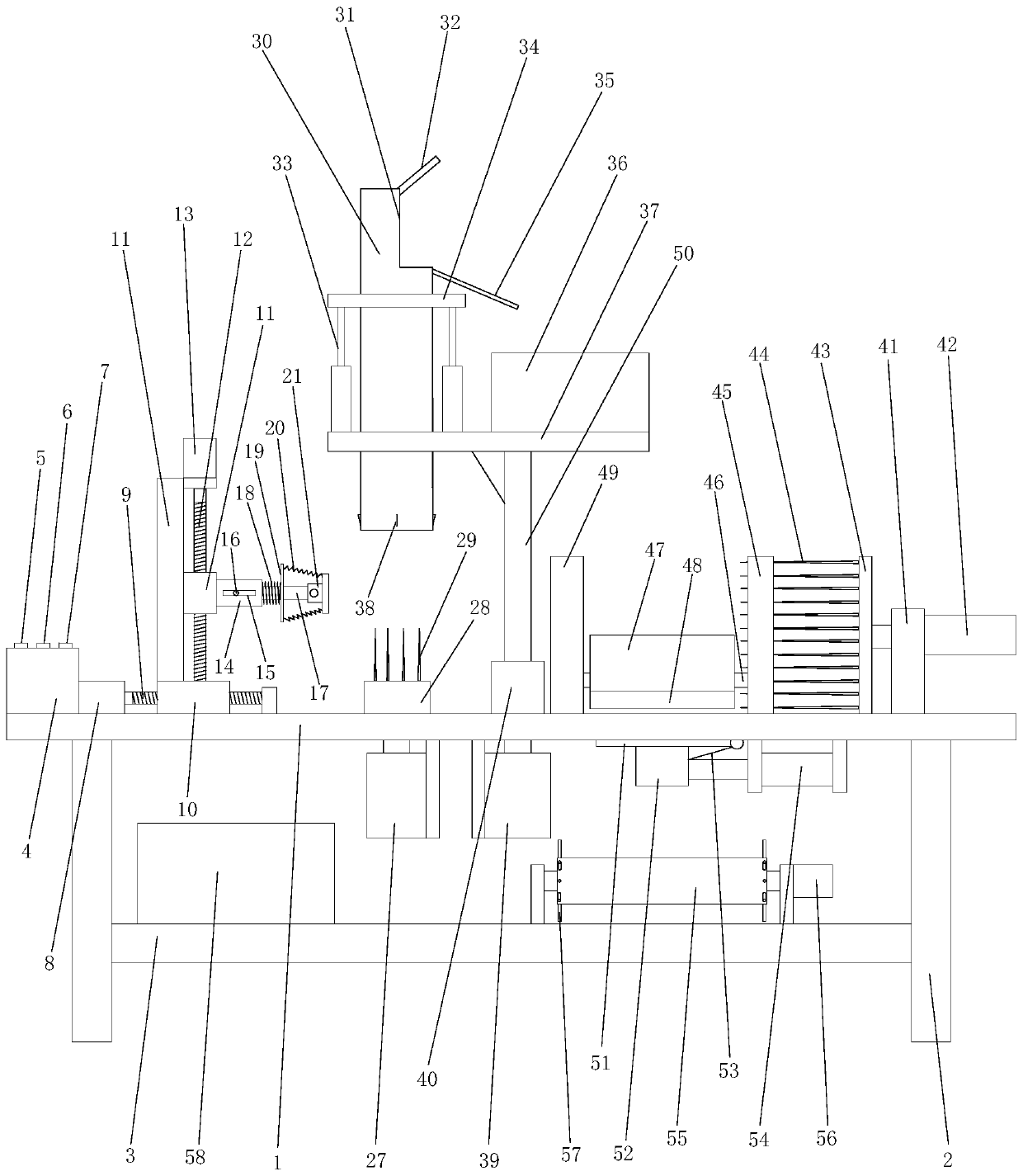

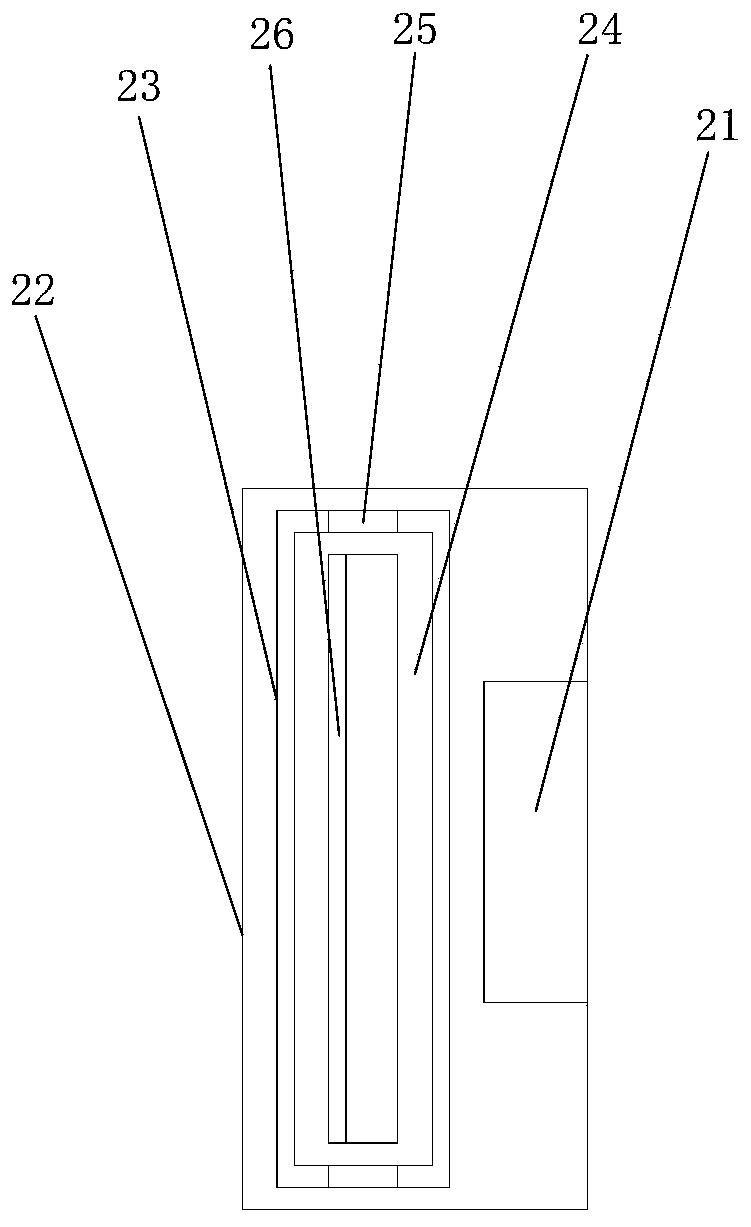

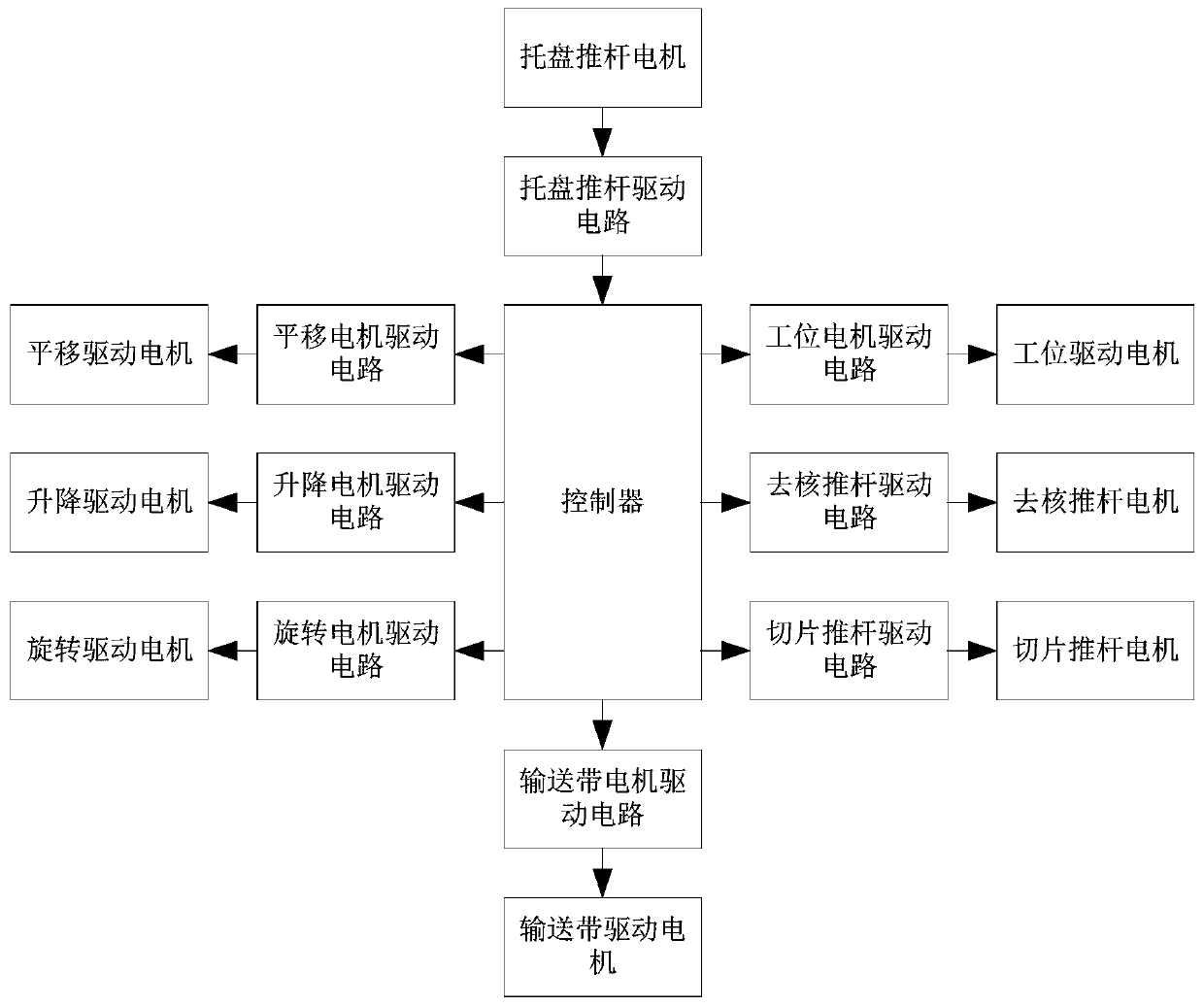

[0018] Such as Figure 1-3 As shown, the apple peeling and slicing integrated machine disclosed by the present invention includes: workbench 1, control box 4, peeling mechanism, core removal and transfer mechanism, and slicing mechanism; control box 4, peeling mechanism, core removal and transfer mechanism, and slice The mechanisms are all installed on the workbench 1; a controller is provided in the control box 4 to drive and control the electric control equipment of the peeling mechanism, the nuclear transfer mechanism and the slicing mechanism respectively; the peeling mechanism is used to rotate and drive the apples. The peeling process is carried out while rotating; the slicing mechanism is used for one-time slicing processing of the peeled apples; the core removal transfer mechanism is located between the peeling mechanism and the slicing mechanism, and is used to remove the core and process the peeling mechanism The final apples are transferred to the slicing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com