Numerical control engraving machine capable of self-adaptive adjusting of workpieces

An adaptive adjustment, CNC engraving machine technology, applied in engraving, processing models, decorative arts, etc., can solve problems such as machine tool vibration, workpiece position offset, product processing problems, etc., to achieve the effect of simple control structure and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

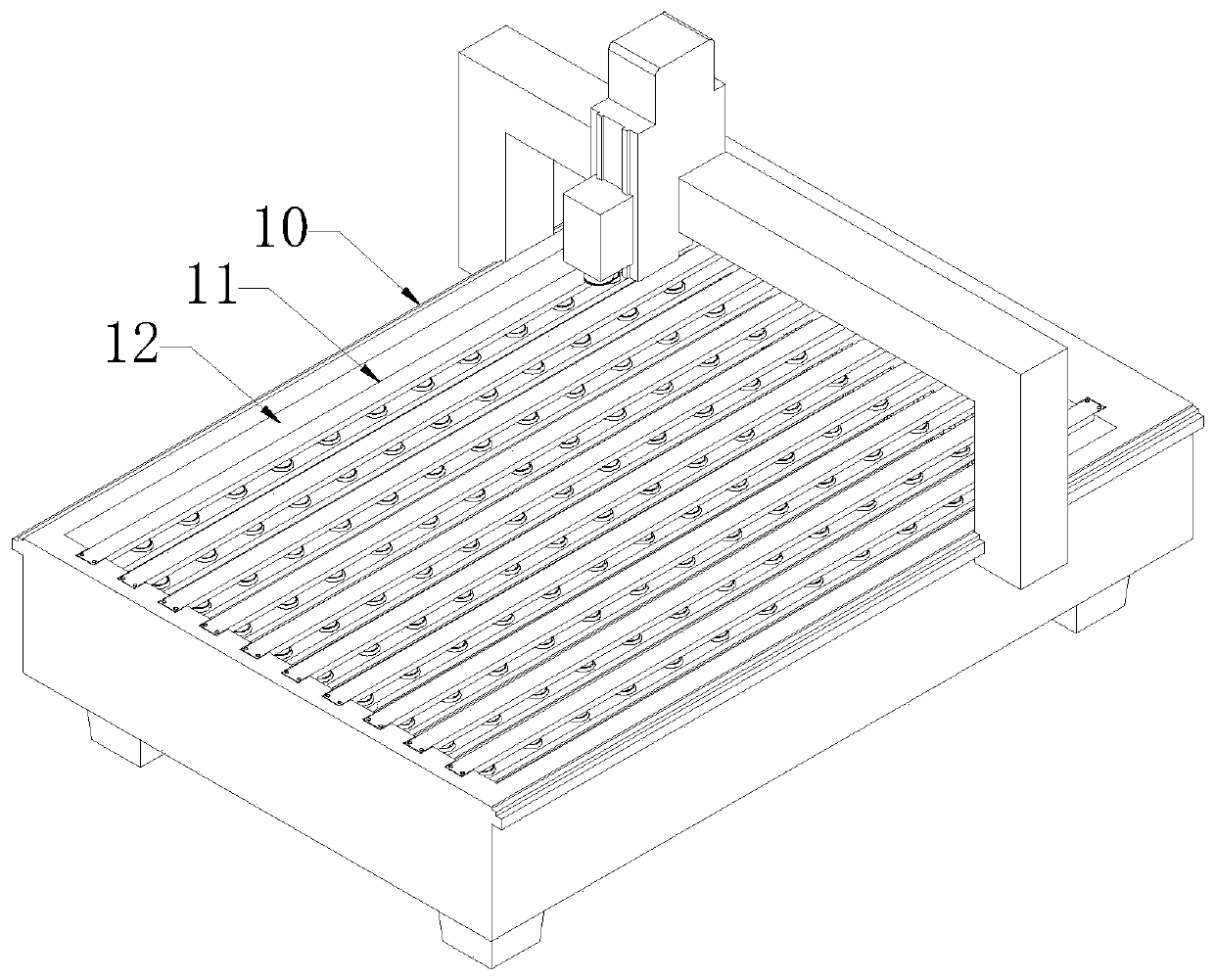

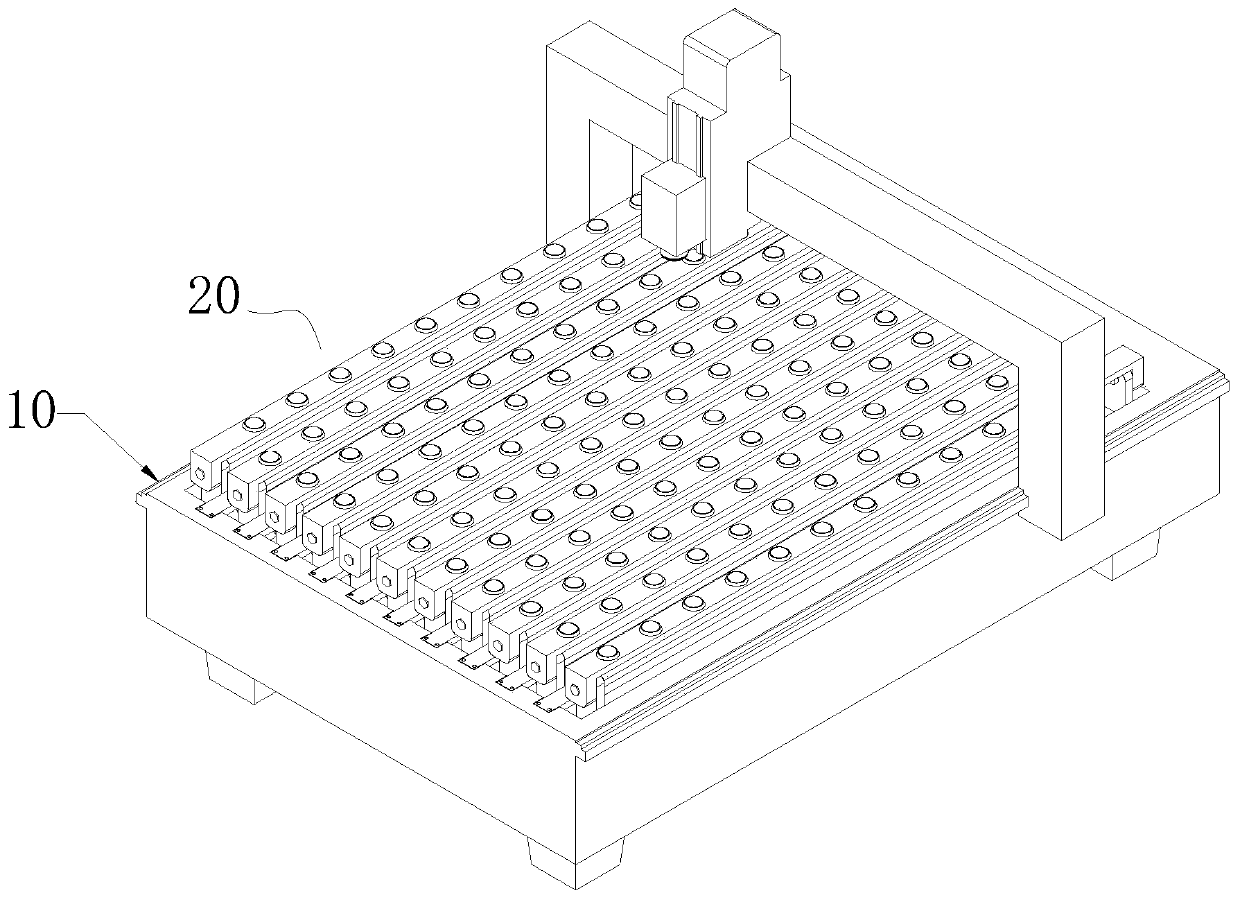

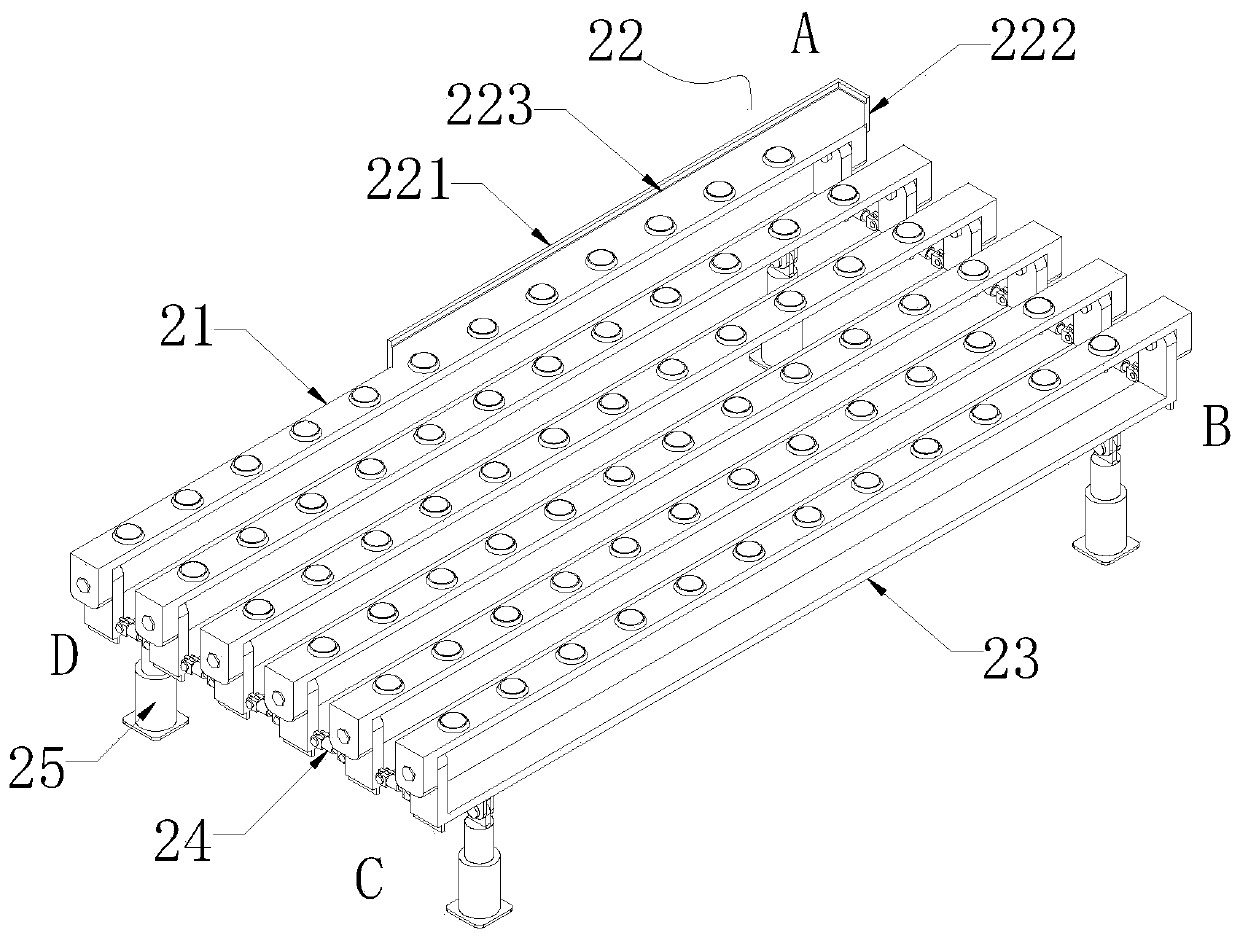

[0021] Such as Figures 1 to 3 As shown, the CNC engraving machine for workpiece self-adaptive adjustment includes a frame 10, a grid plate 11 fixedly installed on the top surface of the frame 10, a chip collection groove 12 is provided below the grid plate 11, and the chip collection groove 12 A telescopic workpiece calibration device 20 is fixedly installed, and the workpiece calibration device 20 includes a top plate 21 for lifting the workpiece, a positioning angle 22 arranged on the top surface of the top plate 21, a support plate 23 connected in rotation with the top plate, and connected adjacent The telescoping device 24 of the support plate 23 and the cylinder 25 that controls the vertical movement of the support plate 23, the positioning angle 22 is set at a corner of the workpiece alignment device 20, the support plate 23 and the grid plate 11 are arranged at intervals, and the cylinder The cylinder base bottom of 25 is fixedly connected with the groove bottom of chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com