Tricycle non-inflatable inner tube

A technology for pneumatic inner tubes and tricycles, applied in non-pneumatic tires, tire parts, vehicle parts, etc., can solve the problems of difficult production process, non-wear resistance, poor cushioning performance, etc., and achieve the effect of eliminating targeted injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

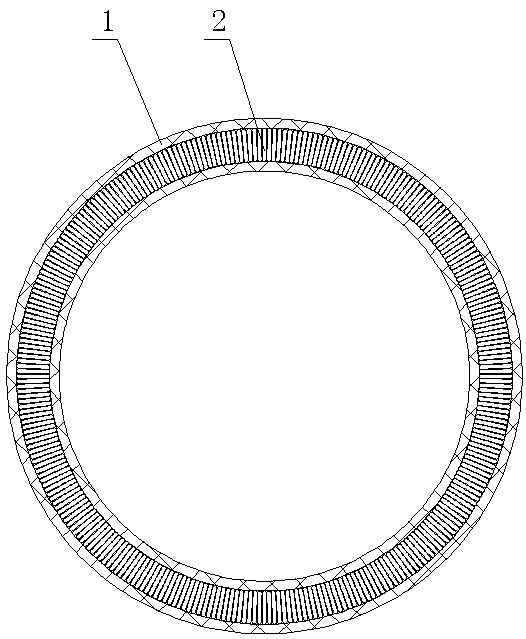

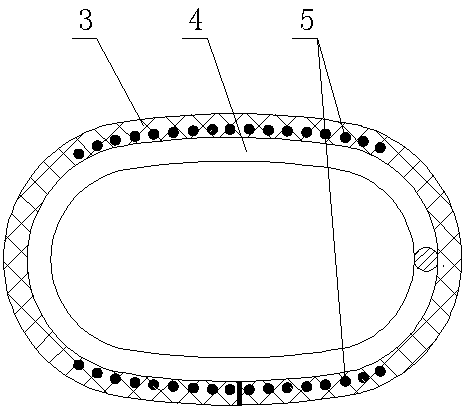

[0023] As shown in the figure, the non-inflatable inner tube of the tricycle is arranged in the outer tire of the tricycle, and serves as an air-filled inner tube; the outside of its lining ring 1 is in contact with the rim of the wheel and the tread inside of the outer tire of the tricycle, and the inside of the lining ring 1 is wrapped in an oval spiral without gaps. On the spring 2; a gap is set on the section 3 of the lining ring 1, which is convenient for setting the elliptical spiral gap spring 2.

[0024] Elliptical spiral gapless spring 2 is a helical spring made of spring wire coils, there is no gap between the round and flat oval circles, and then it is wound into a circle; its cross section 4 is round and flat Oval shape, it is in full contact with the inside of the tire tread and fits completely, supporting the load bearing of the tire tread;

[0025] Steel wire rings 5 are densely covered in the upper and lower parts of the lining ring 1 to offset the targeted d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com