Garbage can

A technology for garbage cans and garbage, applied in the field of garbage cans, can solve the problems of garbage mutual contamination, inability to adjust, mold generation, etc., and achieve the effect of improving compression efficiency and compression performance, preventing mutual contamination, and improving cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

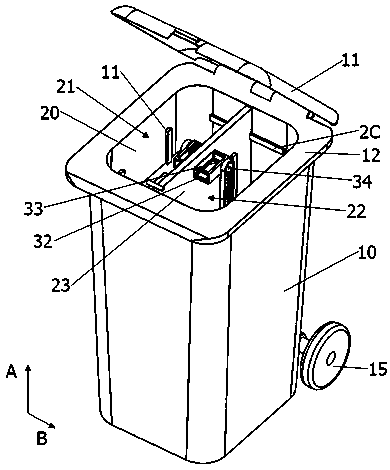

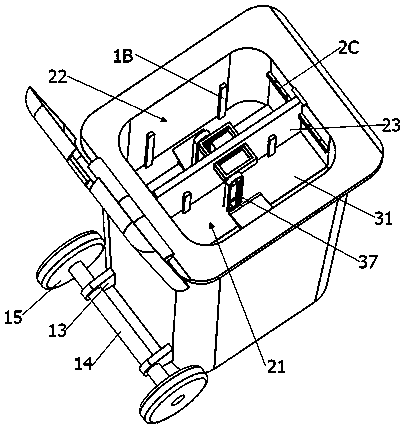

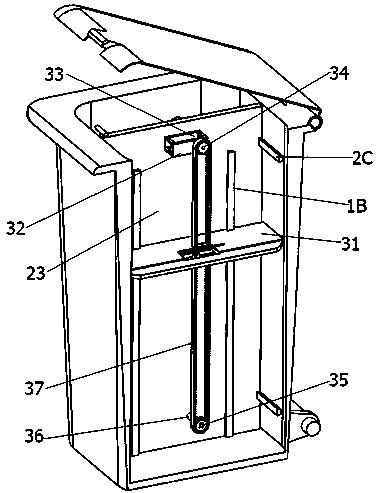

[0019] The application of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. See Figure 1-8 As shown, the application of the present invention provides a trash can, including an outer bucket 10 , an inner bucket 20 and a door cover 11 . The inner barrel 20 is sleeved in the outer barrel 10, and the interior of the inner barrel 20 is a hollow cavity, and the inner barrel 20 is used for storing garbage. Flanges 12 are provided on the upper edge of the outer tub 10, and the door cover 11 is hingedly connected to the flaps 12, so that the door cover 11 is hinged on the outer tub 10 relative to the rotation of the outer tub 10, thereby realizing the opening or closing of the inner tub 20. The cavity makes it convenient for the user to put garbage into the inner bucket 20 or close it to put garbage into the inner bucket 20 .

[0020] In order to classify the garbage stored in the inner bucket 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com