Device and process for removing water bubbles on side surfaces of segments

A technology for air bubbles and segments, which is applied to the equipment and process fields for removing water bubbles on the side of segments, can solve the problems of difficult to grasp, unsatisfactory, and difficult to select the time and operation process of the secondary vibration, so as to reduce the secondary vibration. The process of pounding and inserting the thin iron sheet into the lead row, easy to use and operate, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

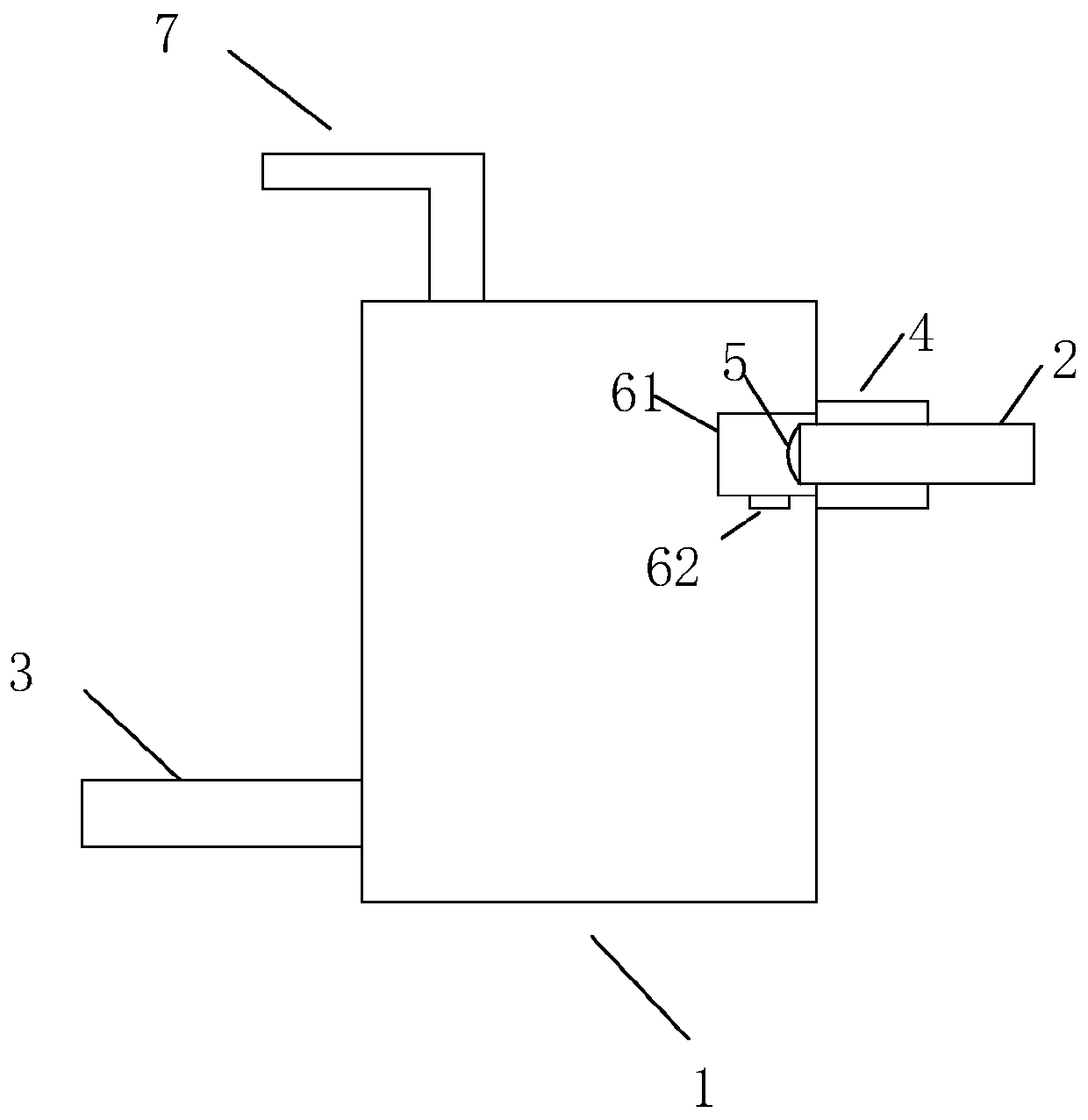

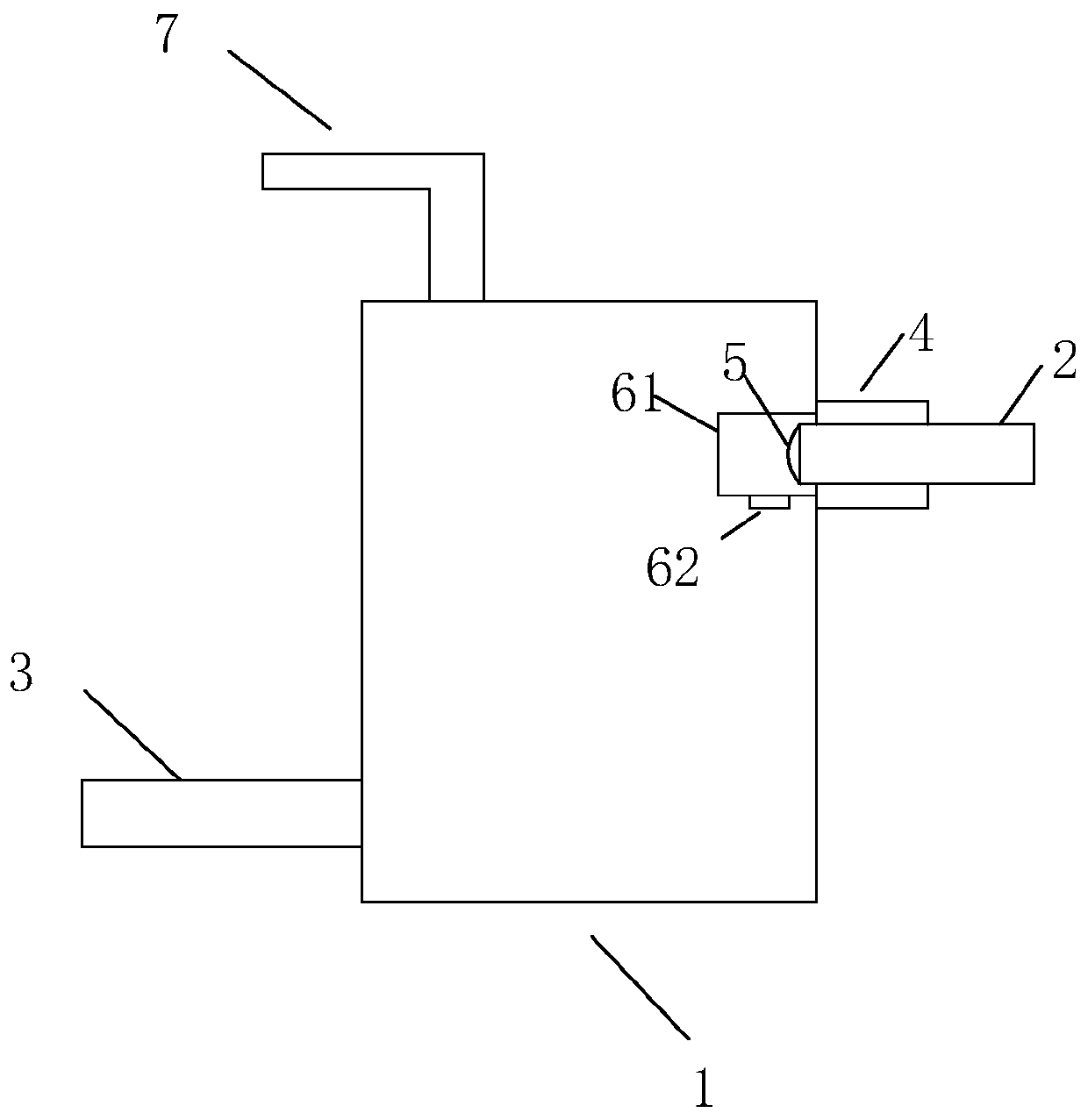

[0022] Such as figure 1 As shown, a device for removing water bubbles on the side of a segment includes a high-pressure sealed barrel 1, a water inlet pipeline 2, a water outlet pipeline 3, a heater, an atomizing nozzle 5, an oscillator and an air pump 7.

[0023] The air pump 7 is communicated with the high-pressure sealed barrel 1, and the air pump 7 is connected to the top of the high-pressure sealed barrel 1 through a pipeline, and the periphery of the pipeline is sealed.

[0024] One end of the water inlet pipeline 2 communicates with the high-pressure sealed barrel 1 and is provided with an atomizing nozzle 5. The atomizing nozzle 5 is arranged on the inner wall of the high-pressure sealed barrel 1, the heater is arranged on the water inlet On the side wall of the sealed barrel 1, the oscillator includes an oscillating cover 61 and an oscillation generator 62 arranged on the atomizing nozzle 5; the heater includes a heating jacket set on the water inlet pipeline 2 4. Th...

Embodiment 2

[0026] A process for removing water bubbles on the side of a segment. Before pouring concrete and during concrete curing, the device in Embodiment 1 is used to remove bubbles and dissolved oxygen for the water inflow and curing of concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com