Free-cutting concrete

A concrete and free-cutting technology, applied in the field of concrete, can solve problems such as shortening the construction period and speeding up the construction speed, and achieve the effect of filling the gaps in research and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0010] Hereinafter, the present invention will be further described with reference to the embodiments, which are only used for explanation and not for limiting the protection scope of the present invention.

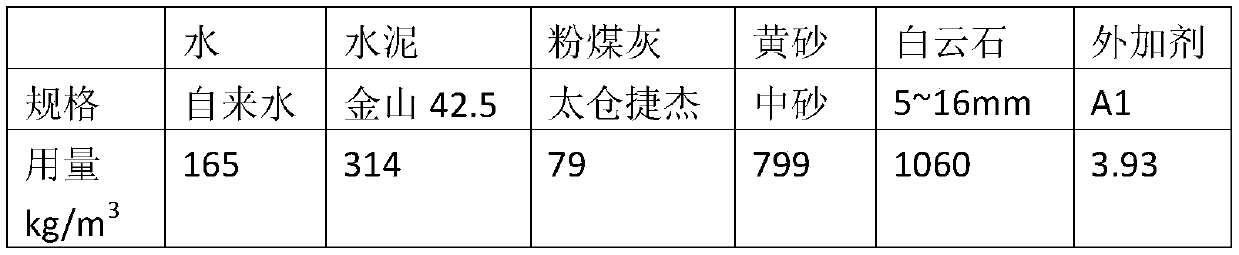

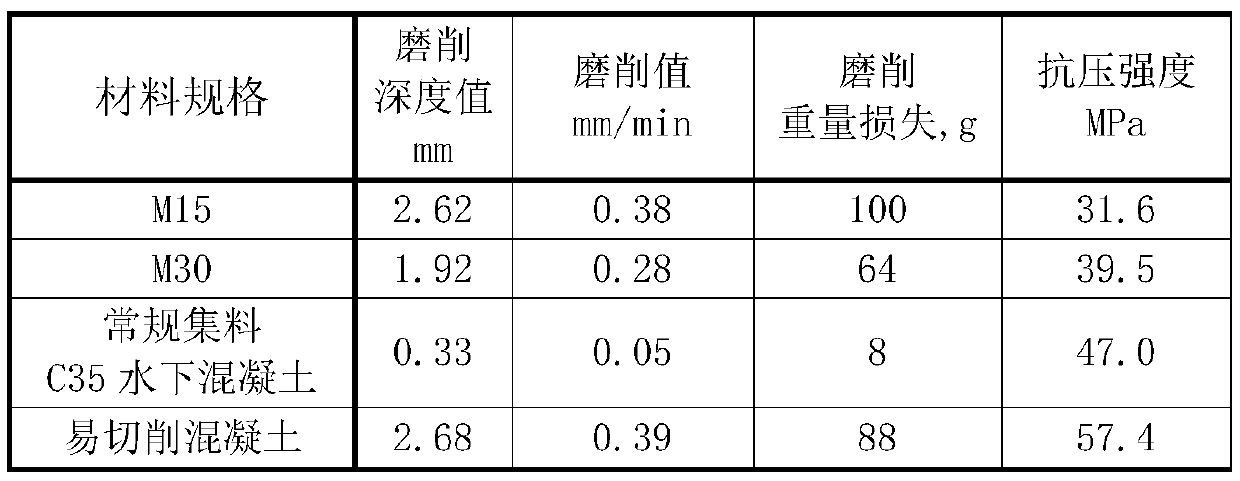

[0011] In the embodiment, a dolomite material that is not commonly used in existing concrete is added. Due to the brittleness of dolomite, in order to prevent the degradation of concrete performance, dolomite is generally avoided. This application provides a concrete mix ratio through specific research on the mix ratio. Under this mix ratio, the characteristics of the dolomite itself can be used in the concrete, while simultaneously taking into account the cutting and grinding performance and the concrete itself Strength, get a concrete mix ratio containing dolomite, as follows.

[0012] This embodiment provides a free-cutting concrete, which is composed of 10-20% of the total weight of cementitious material, 28-35% of yellow sand, 40-45% of dolomite, and the balance of water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com