A ripple spring anti-vibration one-way valve

A corrugated spring, one-way valve technology, applied in the direction of valve device, control valve, functional valve type, etc., can solve the problems of supercharging system structure damage, valve function failure, affecting supercharging system, etc., and achieves short vibration interval, The effect of low pressure loss and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

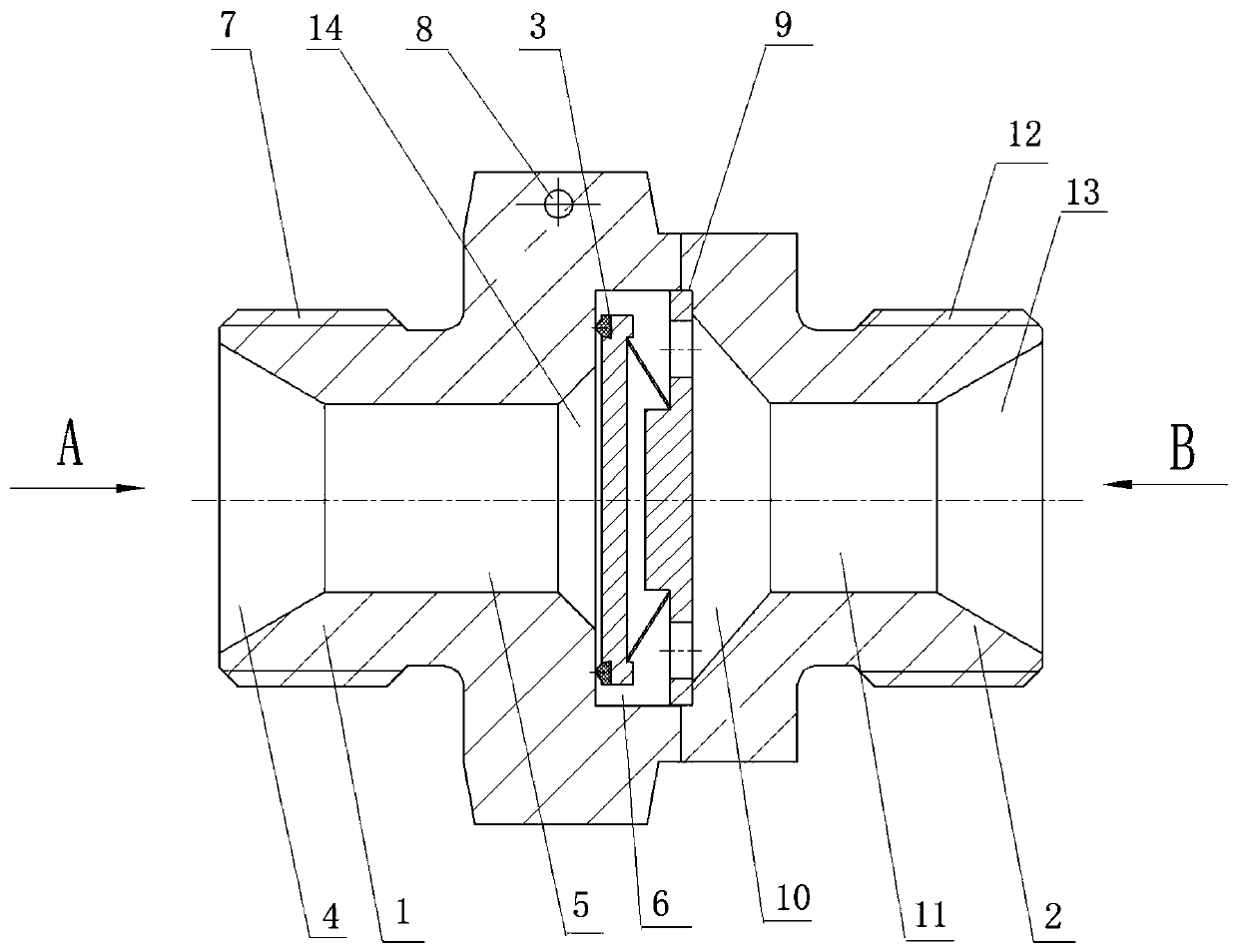

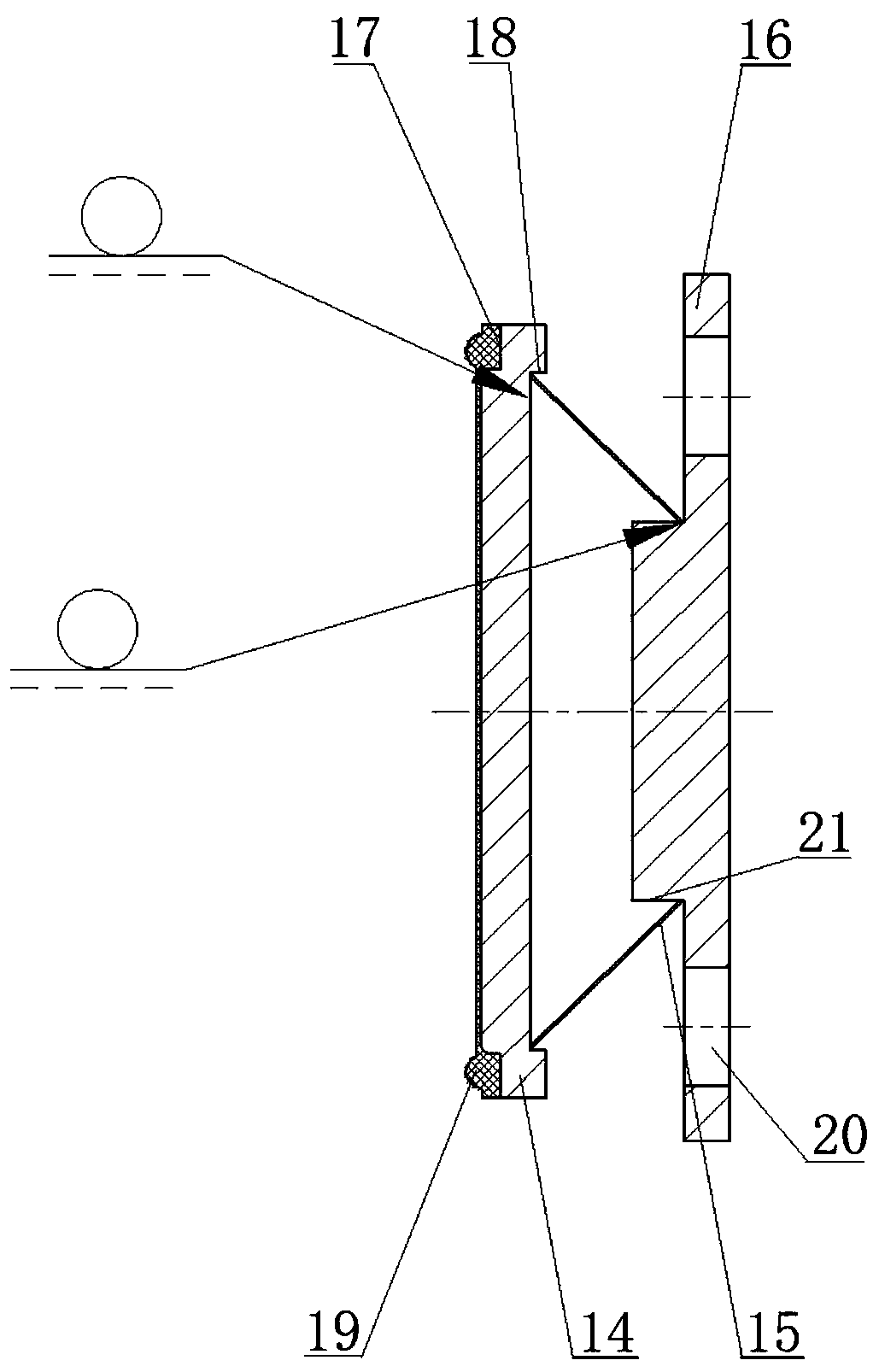

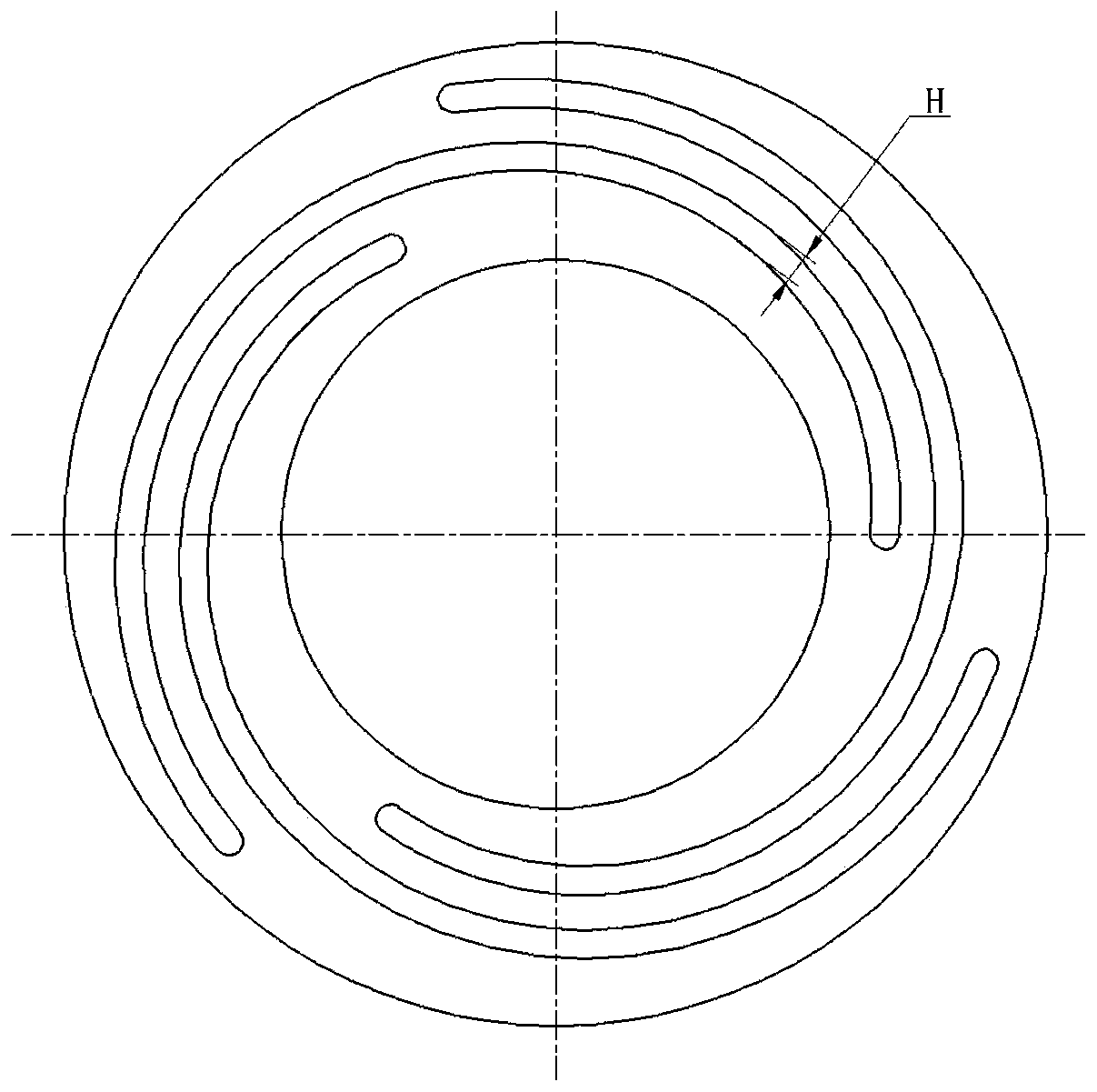

[0027] see figure 1 , a corrugated spring anti-vibration one-way valve of the present invention includes an inlet nozzle 1, an outlet nozzle 2, and a poppet valve 3; the right end surface of the inlet nozzle 1 has a first concave cavity 6, and the left end surface has a first cavity 6. A conical surface cavity 4, the first concave cavity 6 and the first conical surface cavity 4 are communicated by the first through cavity 5, and the three cavities are coaxial; the left end surface of the outlet nozzle 2 has a second concave cavity 9, its right end face has a second conical surface cavity 13, the second concave cavity 9 and the second conical surface cavity 13 are communicated by the second through cavity 11, and the three cavities are coaxial; the inlet nozzle 1 and the When the outlet connecting nozzle 2 is docked left and right, the right end surface of the inlet connecting nozzle 1 and the left end surface of the outlet connecting nozzle 2 are closely attached, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com