Automatic opening locking pipeline connecting mechanism

A connecting mechanism and automatic locking technology, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of lack of flexible and applicable, airtight, reliable, stable and durable pipeline connection mechanism, etc., so that it is not easy to wear and improve sealing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

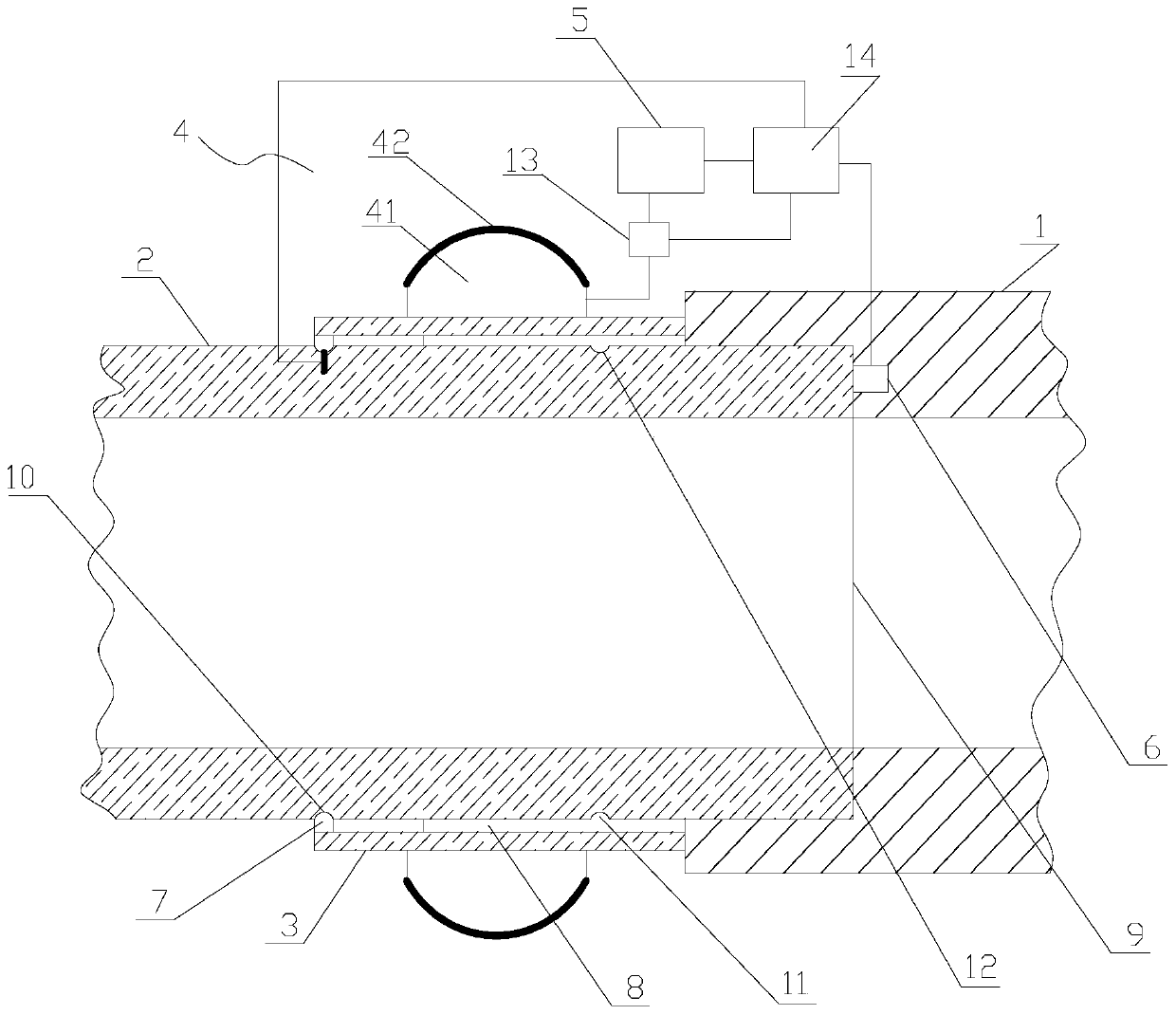

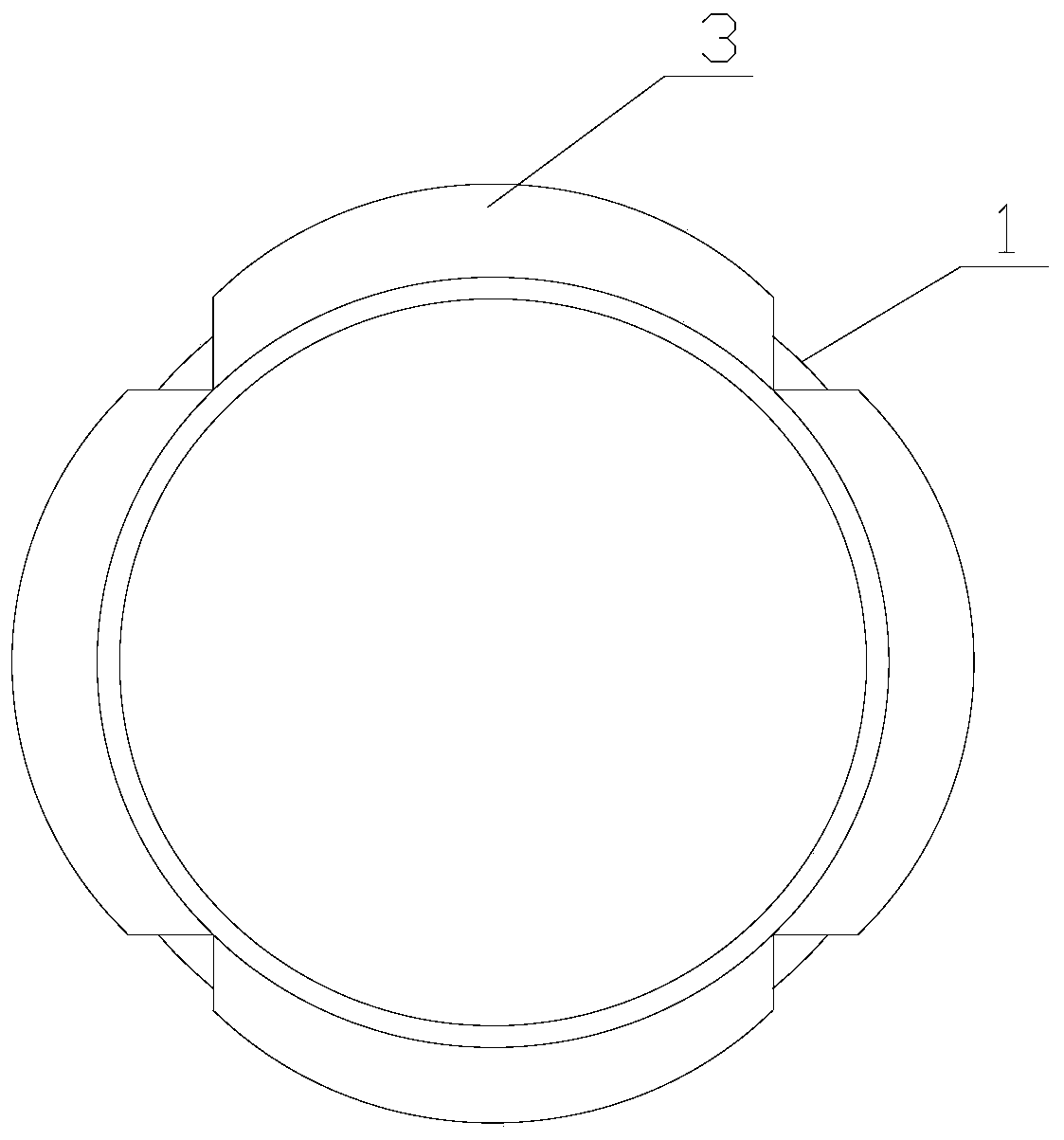

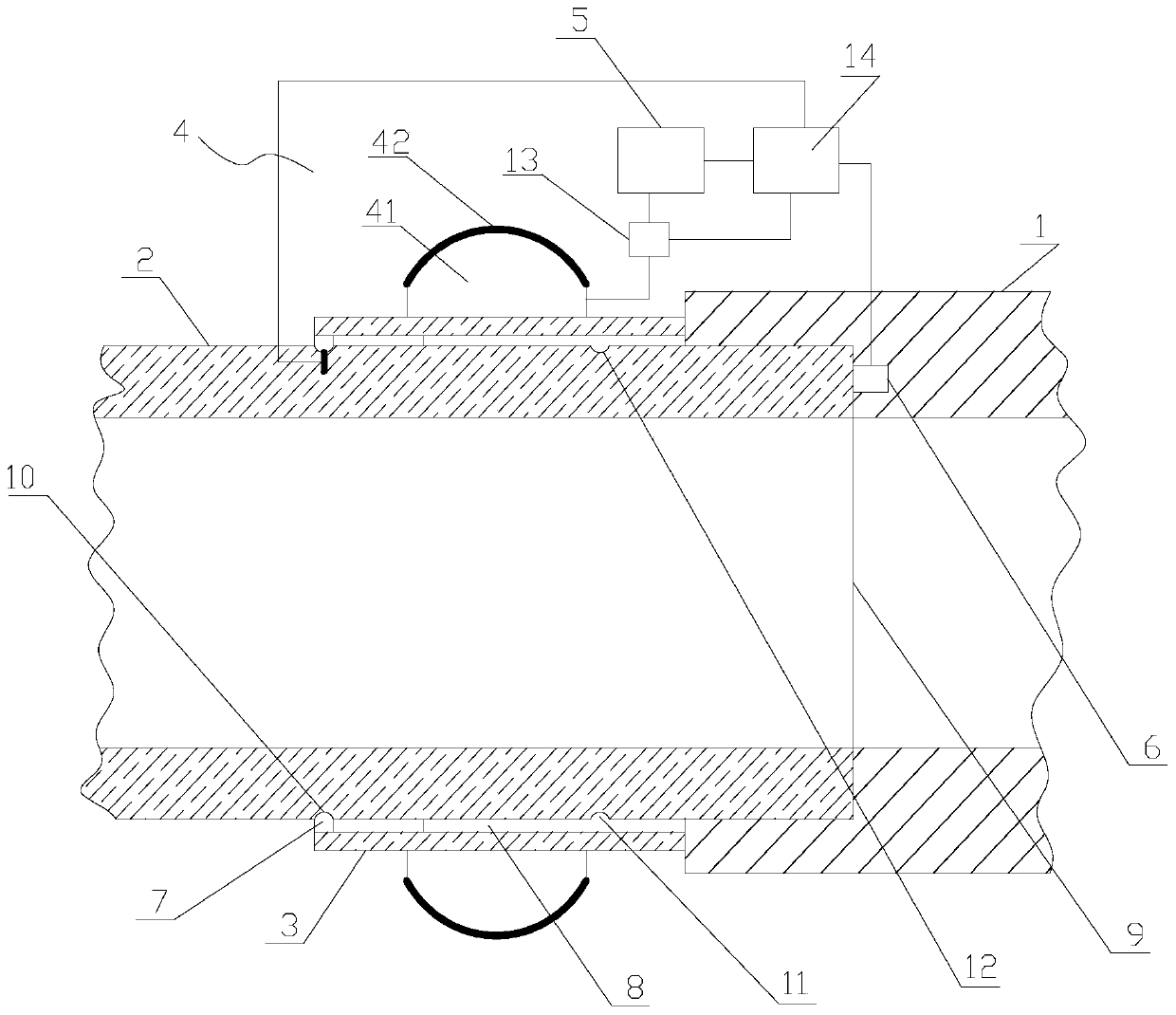

[0017] refer to figure 1 , 2 , an automatic locking pipe connection mechanism of the present invention, including a first connecting head 1, a second connecting head 2, several elastic clamping bodies 3, a pressure tightening mechanism 4, a boosting mechanism 5, a first contact switch 6, several Fix the protrusion 7, the annular flexible pad 8 and the microcontroller 14, and the front end of the first connector 1 is provided with evenly distributed elastic clamping bodies 3, and the elastic clamping bodies 3 are inclined outwards, so that The inner side of the elastic clamping body 3 is provided with a ring-shaped flexible gasket 8 whose rear end is in sealing connection with the first connector 1, and the inner side of the front end of the elastic clamping body 3 is provided with a fixed protrusion 7, and the pressure beam The tightening mechanism 4 is fixedly sleeved on all the elastic clamping bodies 3, the pressurizing mechanism 5 is connected with the pressure tightening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com