High-performance electrical engineering distribution circuit breaker

An electrical engineering and high-performance technology, applied in circuits, electrical components, electrical switches, etc., can solve the problems that the heat of electrical devices cannot be dissipated quickly, and the gap between internal components is small, so as to achieve uniform force application, increase speed, and contact big face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

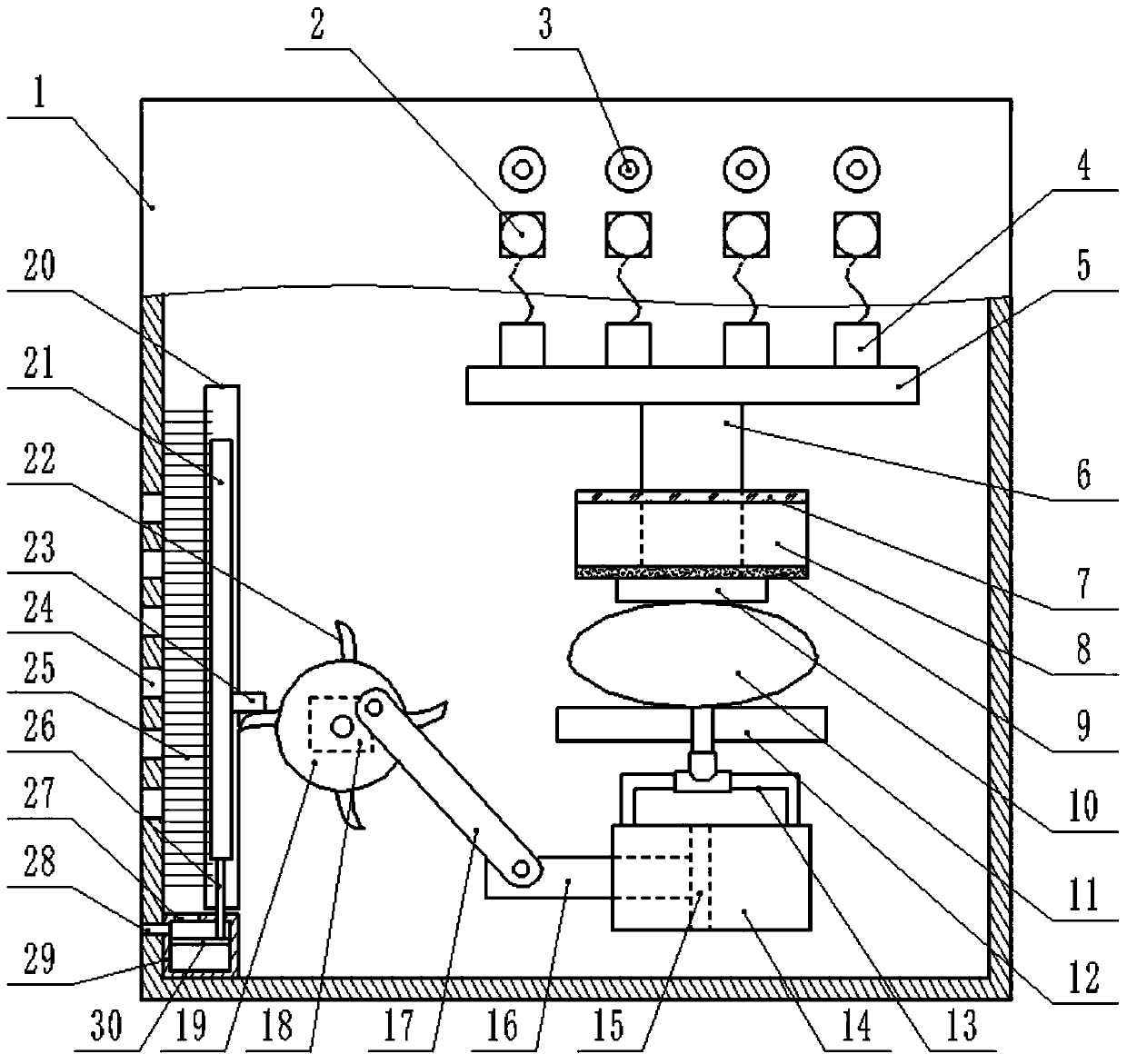

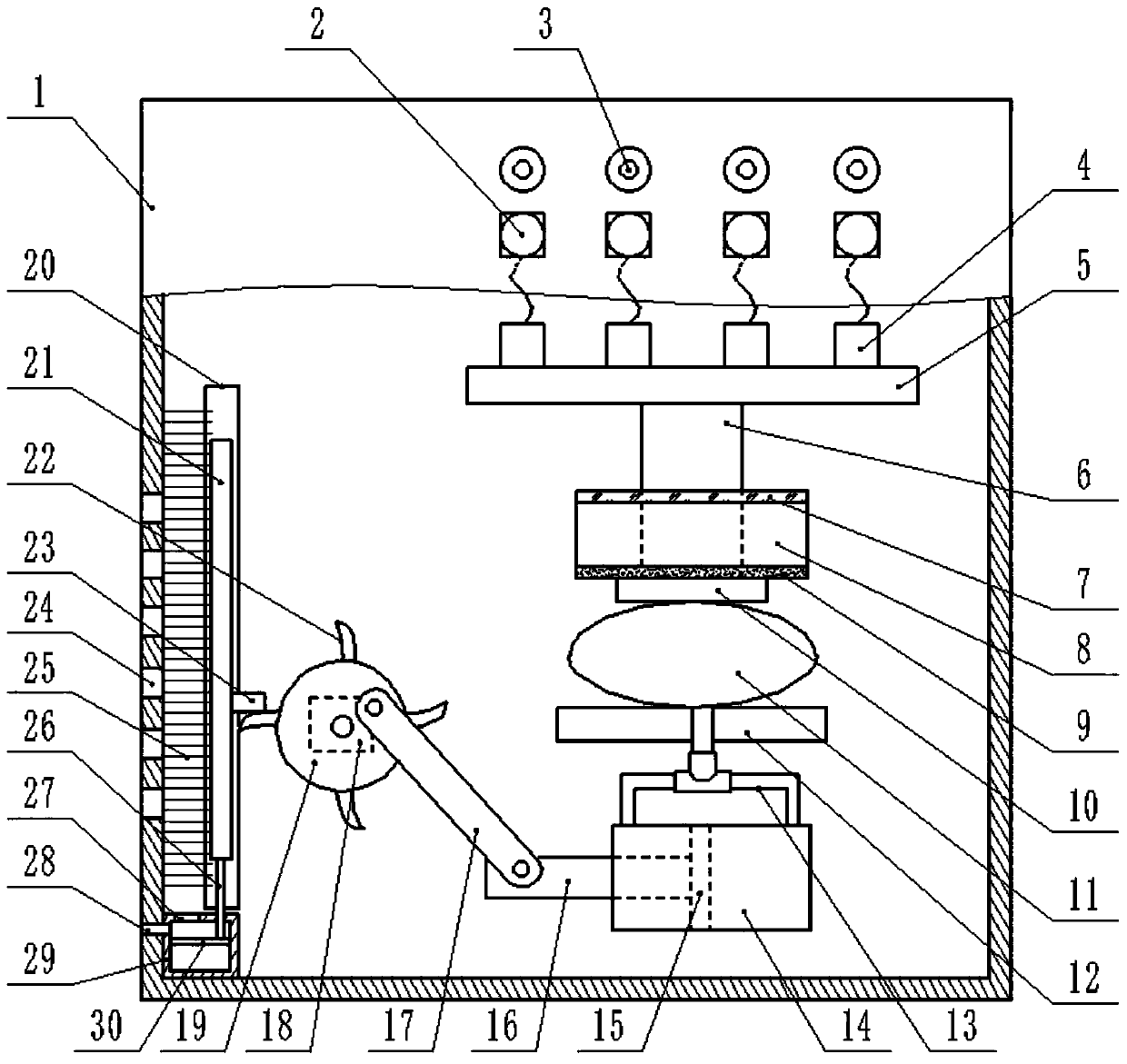

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0029] The application principle of the present invention will be further described below in conjunction with accompanying drawings and specific embodiments:

[0030] The reference signs in the drawings of the description include: cabinet body 1, terminal post 2, installation hole 3, conductive block 4, conductive plate 5, insulating rod 6, insulating cushion 7, insulating plate 8, buffer pad 9, support plate 10 , air bag 11, fixed plate 12, air pipe 13, cylinder body 14, first piston 15, connecting rod 16, rocker 17, motor 18, disc 19, slide rail 20, ash-shielding plate 21, arc blade 22, fixed Block 23, vent hole 24, bris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com