Safe and reliable composite coupler and food processing machine

A technology of food processing machines and couplers, which is applied in the direction of coupling devices, components of connecting devices, and devices for preventing wrong connections, etc., which can solve the problems of complicated setting on the upper surface of the machine base, larger volume of food processing machines, and production and maintenance efficiency. Low-level problems, to achieve the effect of compact structure, reduced assembly size and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

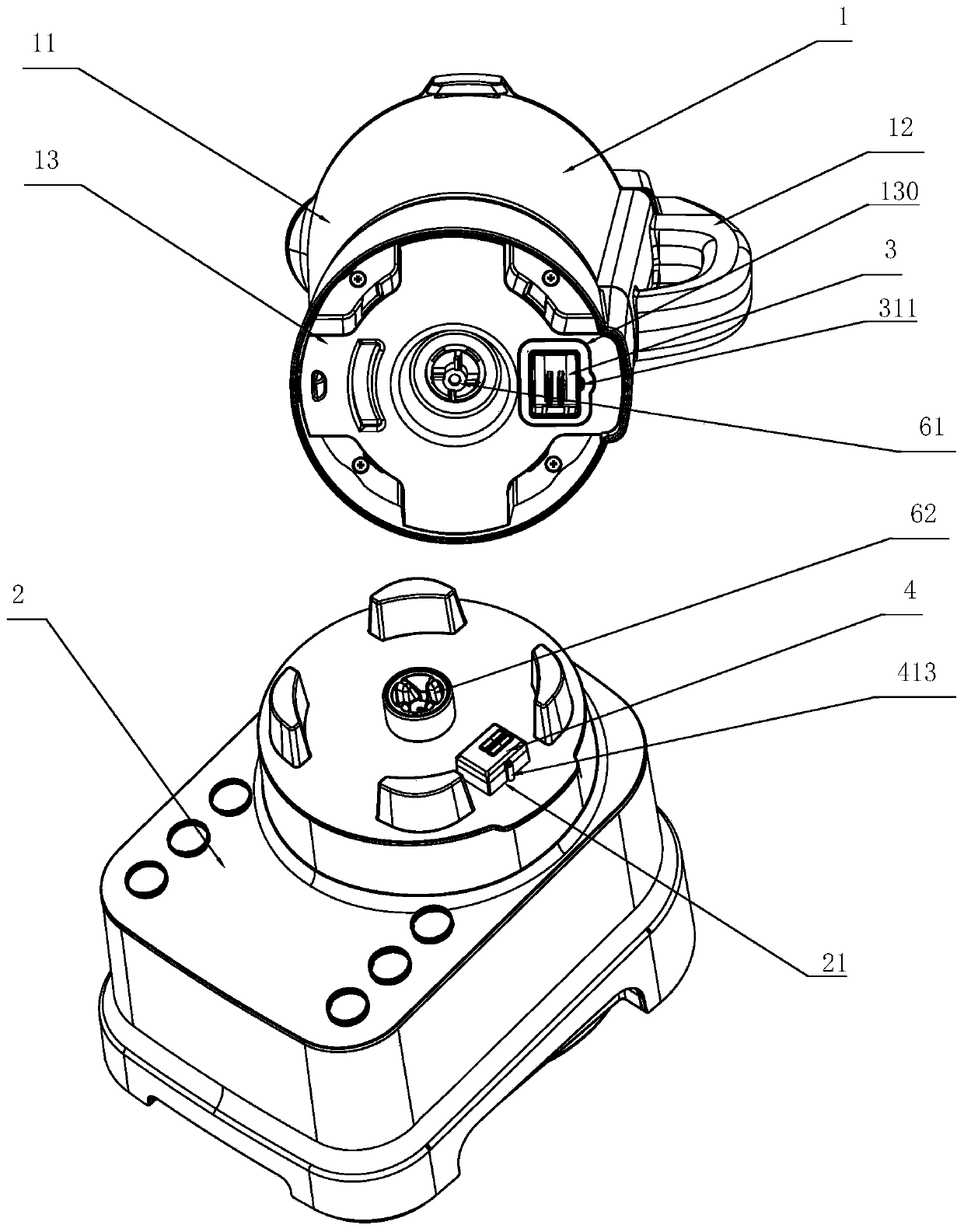

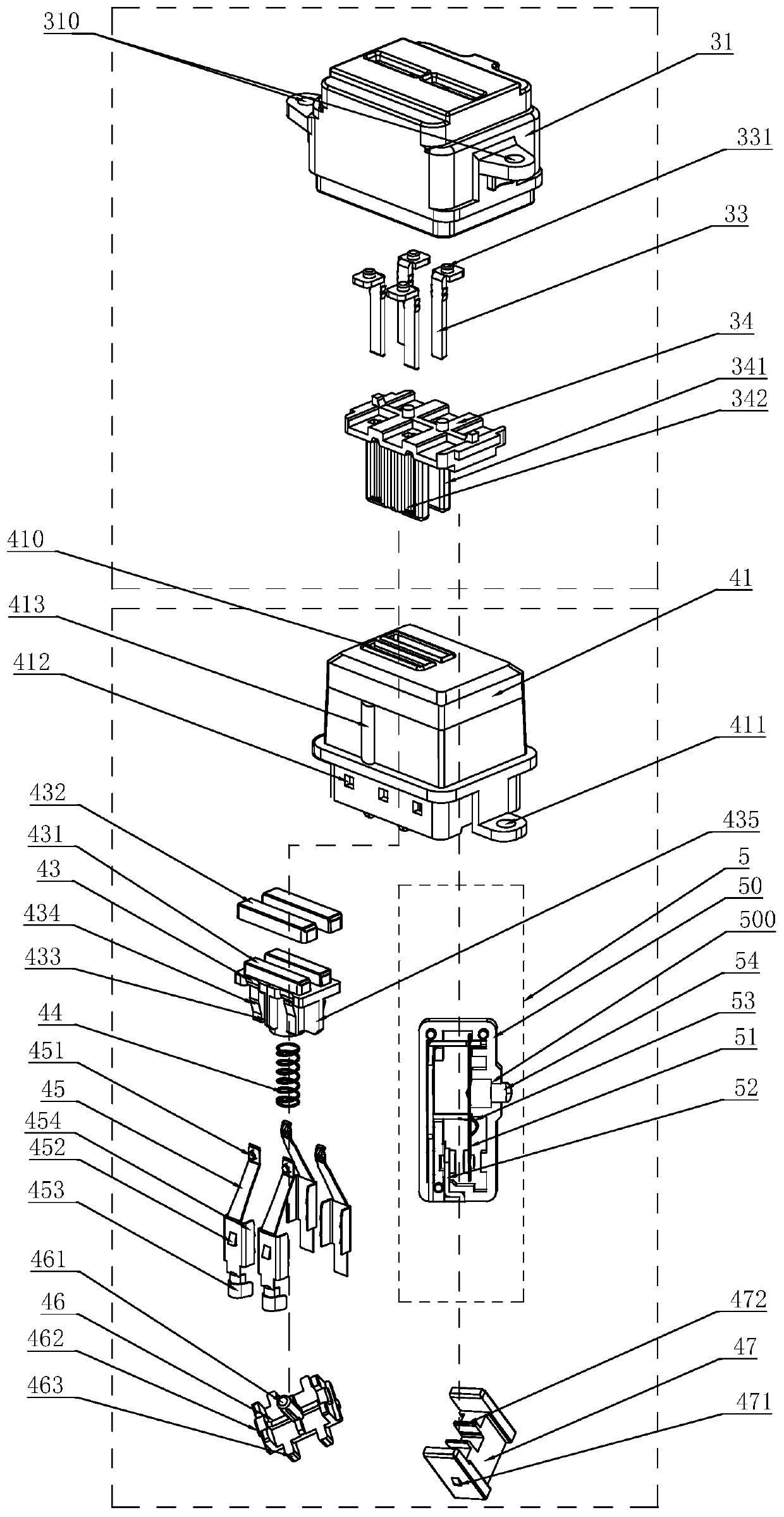

[0053] Such as Figure 1-6 As shown, the present invention provides a safe and reliable food processing machine coupler assembly and food processing machine, the food processing machine includes a machine base 2 and a stirring cup 1 arranged on the machine base 2, and the machine base 2 is equipped with There is a motor and a control board (not shown in the figure), and the stirring cup 1 includes a cup body 11, a cup cover (not shown in the figure), and a cup holder 13. The upper end of the cup body 11 is provided with an opening. The cover is arranged at the opening, the side wall of the cup body 11 is provided with a handle 12, and the cup body 11 is provided with a pulverizer driven by a motor (not shown in the figure), and the motor is connected to the lower connecting shaft 62 connection, the pulverizer is connected with the upper coupling 61, and the upper coupling 61 is connected with the lower coupling 62 power, so that the motor drives the pulverizer. The stirring c...

Embodiment 2

[0077] As the second embodiment of the convenient and safe food processor of the present invention, the main difference from the first embodiment is that the micro switch is not provided with a mounting case.

[0078] Such as Figure 7 , 8 As shown, in this embodiment, the coupler includes an upper coupler 3 and a lower coupler 4 , and the upper coupler 3 includes a fixed shell 31 , an upper electrode 32 and a fixed plate 34 .

[0079] The lower coupler 4 includes a housing 41 , a lower electrode 45 , a micro switch 5 , a first mount 46 , and a second mount 47 . The upper surface of the casing 41 is provided with a first through hole 410 , and the casing 41 is provided with a shroud 43 for covering the first through hole 410 and a first elastic member 44 for pushing the shroud 43 .

[0080] The micro switch 5 includes a moving elastic piece 51 and a static elastic piece 52 , the static elastic piece 51 and the moving elastic piece 52 are mounted on the second mounting seat 4...

Embodiment 3

[0086] As the third embodiment of the convenient and safe food processing machine of the present invention, the main difference from the first embodiment is: the trigger structure of the micro switch is different.

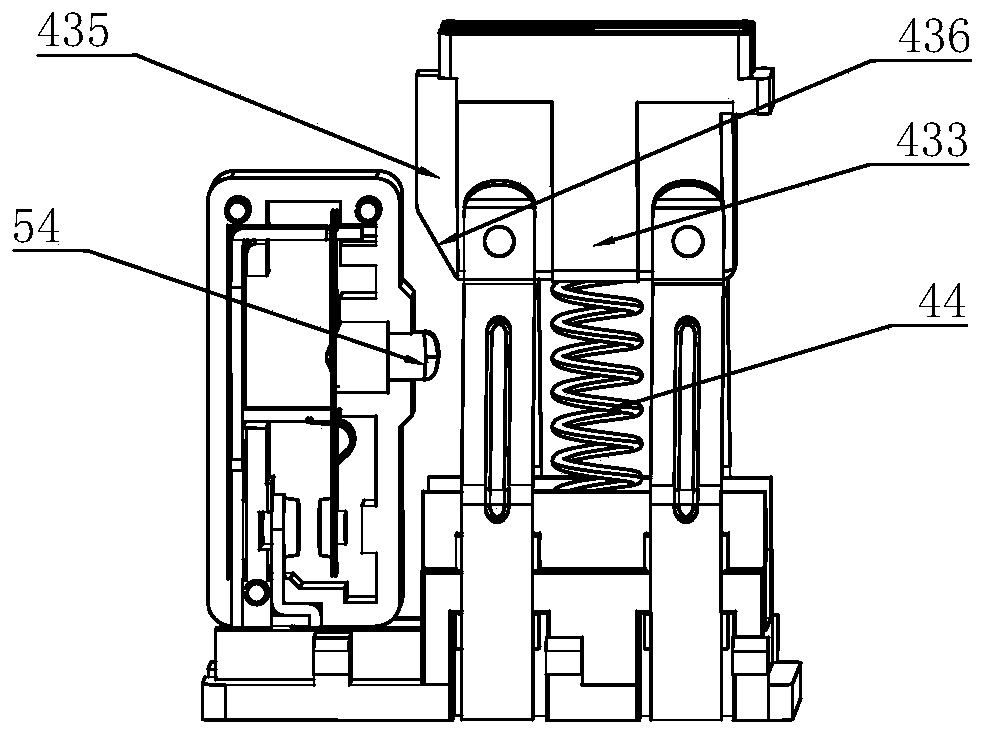

[0087] Such as Figure 9 , 10 As shown, the lower coupler includes a housing 41, the upper surface of the housing 41 is provided with a first through hole 410, and the first through hole 410 is a side-by-side long hole on the side of the lower electrode, and There is a large through hole on one side of the micro switch, so that the first through hole has a "concave" shape as a whole. The upper surface of the shutter 43 is provided with a rib corresponding to the shape of the first through hole 410 for closing the first through hole. The shutter 43 is provided with a pushing portion 435 above the micro switch 5 , preferably, the pushing portion 435 has a slope.

[0088] The micro switch 5 is arranged in the housing 41, the micro switch 5 includes a movable rod 54 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com