Swinging type plug-in structure of bus duct

A technology of plug-in structure and busway, which is applied in the direction of fully enclosed busbar devices, and can solve problems such as poor connection reliability, difficult operation, and difficult insertion into place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

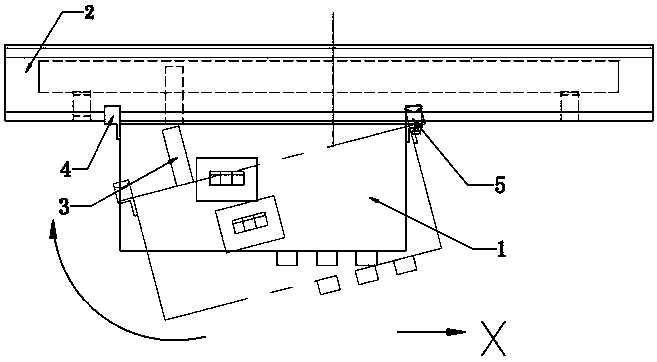

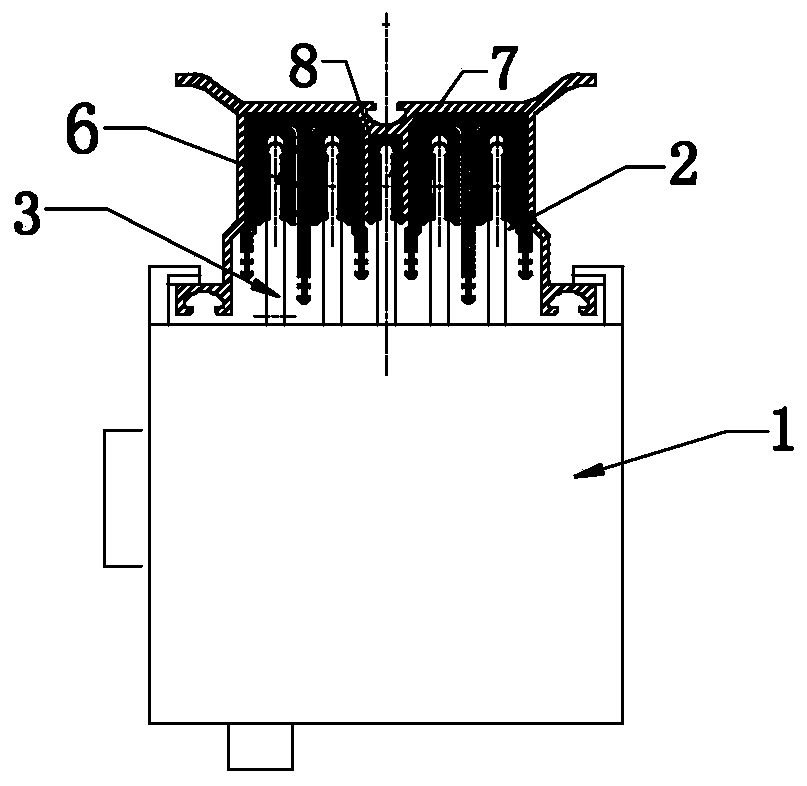

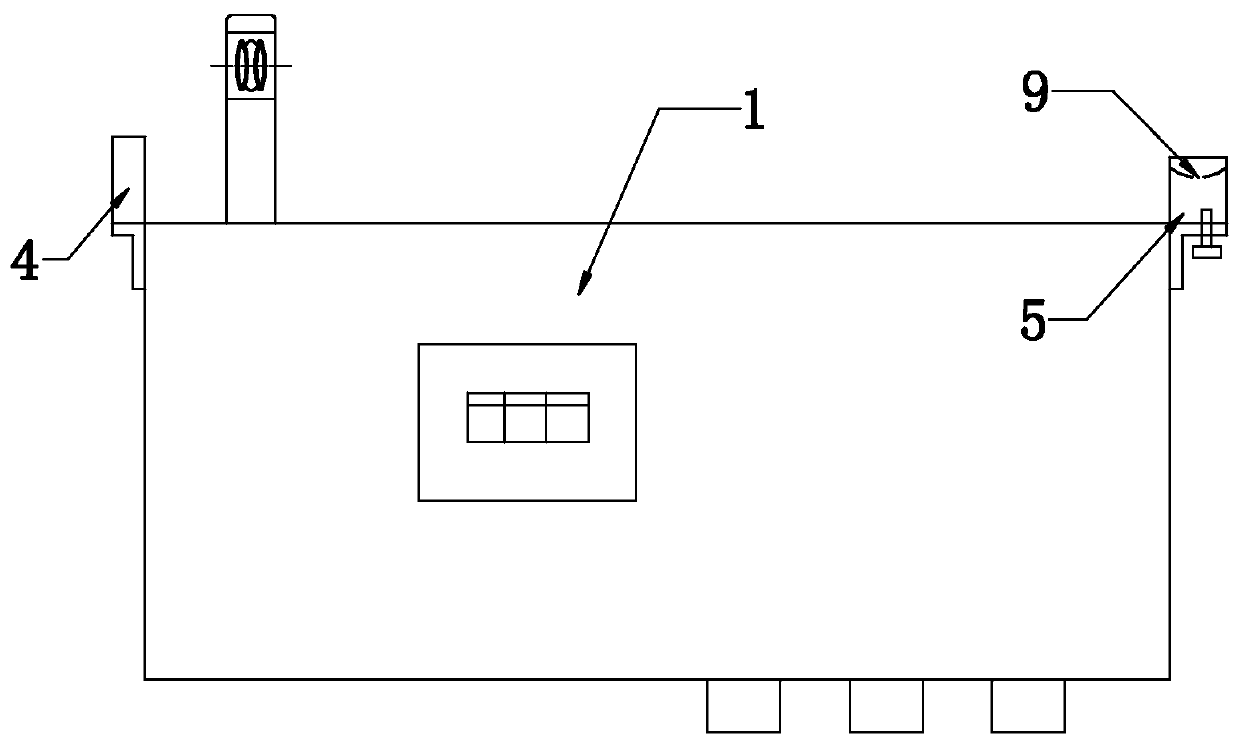

[0017] The swing-type plug-in structure of the bus duct of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] As shown in the figure, the bus duct swing type plug-in structure of the present invention includes a plug-in box body 1 and a multi-phase plug 3 provided in the plug-in box body for electrically connecting the conductors in the bus duct 2, and the plug-in box There is one row of plugs 3 or two rows of plugs 3 on the body 1. When there are two rows of plugs, it can be arranged in 2 / 3, 3 / 2, of course, it can also be arranged in 1 / 4 or 4 / 1. The two sides of the upper front end of 1 are provided with movable hooks 4 installed by torsion spring 4, and the two side edges of busway 2 are provided with hooking positions. , the movable hook 4 is relatively installed on both sides of the upper front end of the plug-in box body 1, the movable hook 4 can be pressed on the hooking positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com