Anti-falling cable branch box

A cable branch box and anti-falling technology, which is applied in the direction of cable joints, etc., can solve problems such as branch box toppling and reinforced cement piers loosening, and achieve the effect of enhancing stability and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

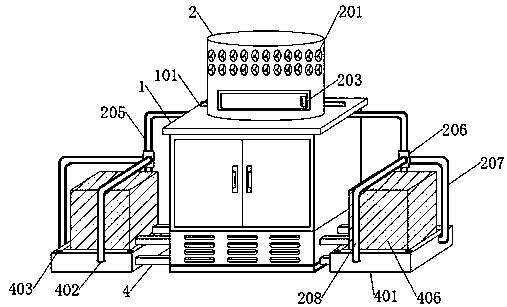

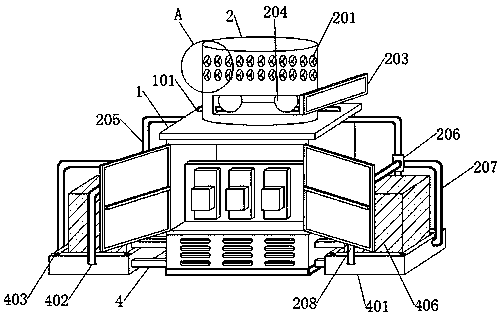

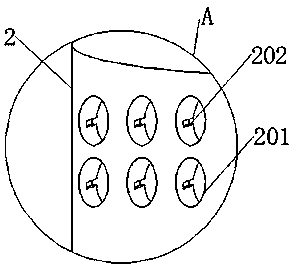

[0028] as attached figure 1 to attach Figure 6 Shown: an anti-fall cable branch box, including a branch box body 1, a first fixing hole 101, an air collecting cover 2, an air inlet hole 201, a limit slot 202, a movable cover 203, an air storage chamber 204, and an air inlet pipe 205, tap sleeve 206, first shunt pipe 207, second shunt pipe 208, air induction groove 3, limit chuck 301, reinforcement rod 4, counterweight chassis 401, second fixing hole 402, bolt hole 403, extrusion Pressing plate 404, extruding block 405 and counterweight 406; first fixing holes 101 are provided on both sides of the upper middle of the branch box 1, and the upper middle of the branch box 1 is welded with the wind collecting hood 2, the wind collecting hood 2 Air inlet holes 201 are arranged all around the upper outer wall, and both sides of the air inlet holes 201 are embedded with limiting slots 202. A movable cover 203 is movably connected under the front of the air collecting hood 2. Both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com