Vehicle driving system

A vehicle drive and vehicle technology, which is applied in the field of rail vehicles, can solve the problems of high operating costs of high-speed rail, and achieve the effects of increasing magnetic driving force, avoiding derailment, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

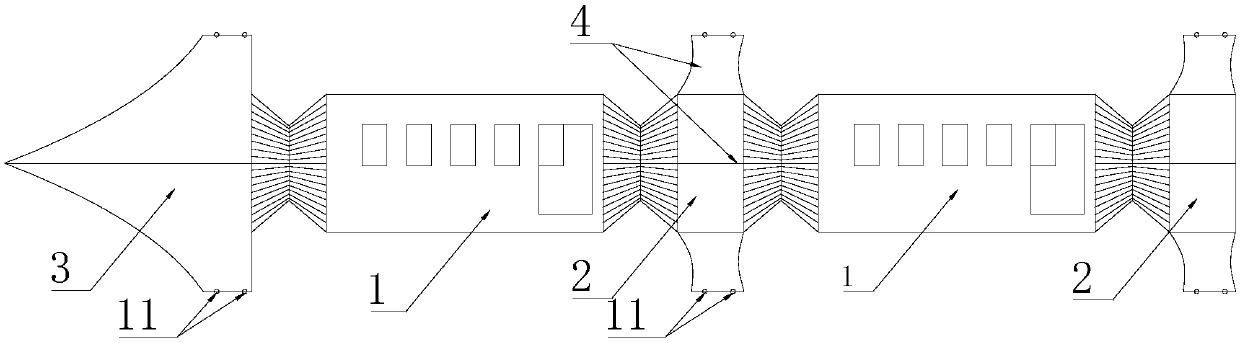

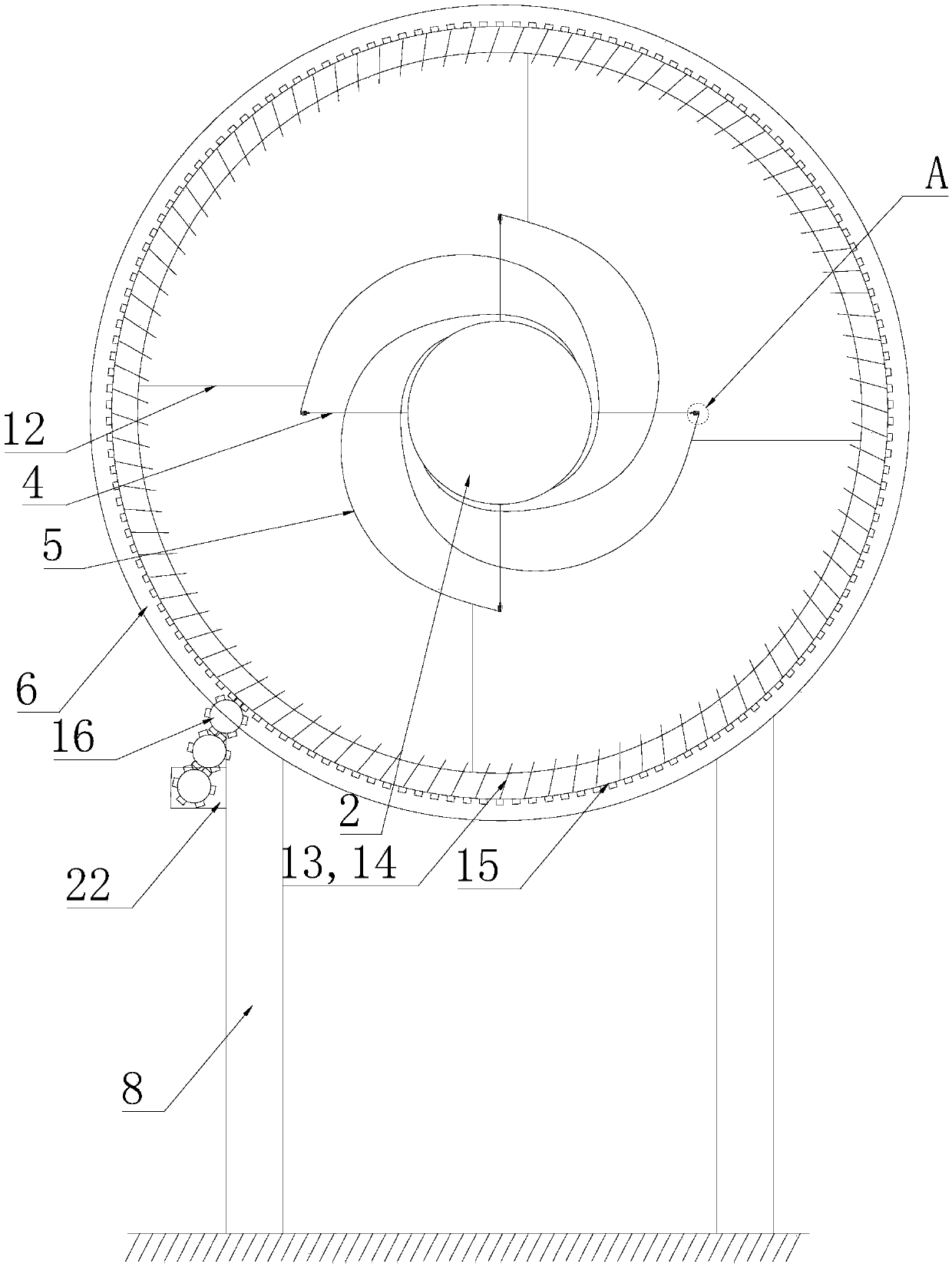

[0044] Such as Figure 1 to Figure 6 As shown, the present embodiment introduces a vehicle drive system. The annular support portion 6 is provided with a coaxial turbine 13 that can relatively rotate around the central axis. The turbine 13 is connected to the output end of the engine 22 through a transmission structure. Engaged, the engine 22 drives the turbine 13 to rotate to generate jet airflow along the centerline direction of the annular support part 6, and the jet airflow pushes the vehicle to move forward.

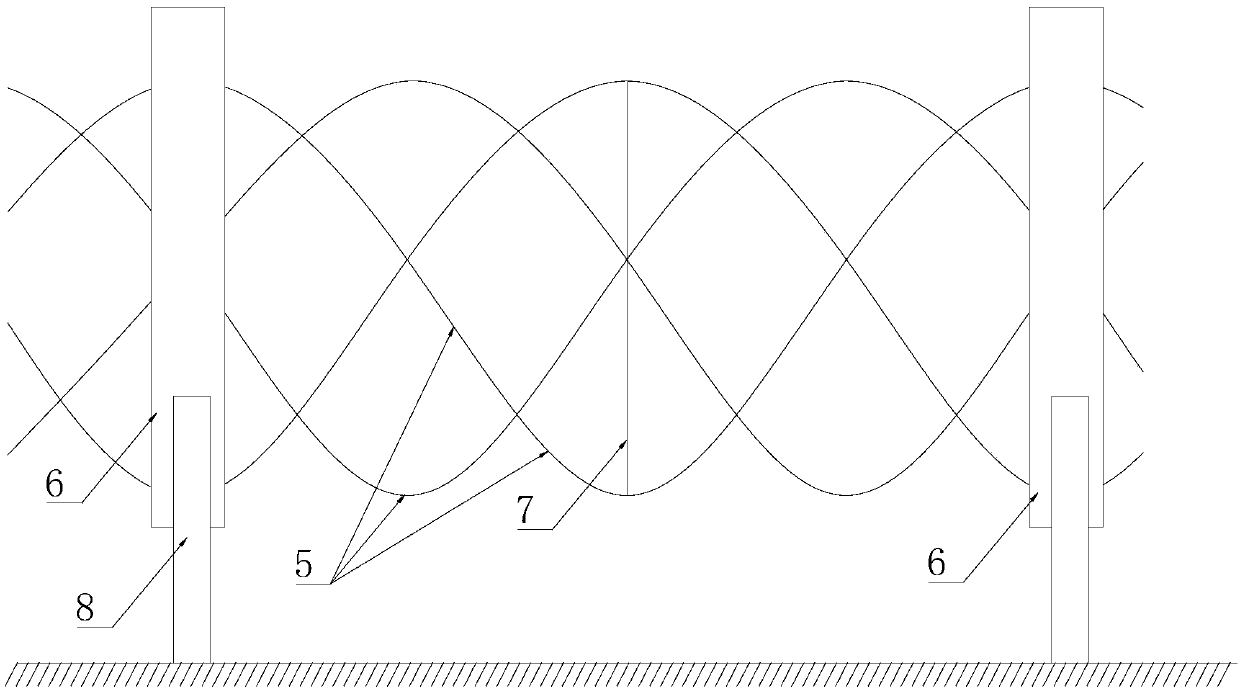

[0045] In this embodiment, the vehicle is provided with a rotating part 2 that can rotate around the moving direction. The outer circumference of the rotating part 2 is provided with wheels 11. The wheels 11 are correspondingly installed into the guide rail 5 extending along the cylindrical helix, so that the rotating part 2 is supported by the guide rail 5. The rotating part 2 is pushed forward by the jet airflow generated by the turbine 13 during the rotation arou...

Embodiment 2

[0050] Such as figure 1 , figure 2 , Figure 4 to Figure 7 As shown, the present embodiment introduces a vehicle drive system. A coil 23 coaxially arranged in the ring-shaped support part 6 is connected to the power supply device, and the power supply device feeds a current to the coil 23 to generate a magnetic field. The vehicle passing through the annular support part 6 is pushed forward by the magnetic driving force generated by the magnetic field.

[0051] In this embodiment, the vehicle is provided with a rotating part 2 that can rotate around the moving direction. The outer circumference of the rotating part 2 is provided with wheels 11. The wheels 11 are correspondingly installed into the guide rail 5 extending along the cylindrical helix, so that the rotating part 2 is supported by the guide rail 5. The rotating part 2 continuously cuts the magnetic field to generate a magnetic driving force during the rotation process, so that the rotating part 2 is affected by the...

Embodiment 3

[0056] This embodiment is based on the above-mentioned embodiment one or two, and also has the following technical features:

[0057] In this embodiment, a starting power system is provided on the vehicle, and the starting power mechanism includes a storage battery and an electric motor arranged on the vehicle. The storage battery supplies power to the motor to drive the output end of the motor to rotate, and the output end of the motor is connected to the wheels 11 through a transmission system to drive Wheels 11 rotate to propel the vehicle forward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com