Marine water spraying type propeller

A technology of water jet and thruster, which is applied in the direction of ship propulsion, propulsion parts, ship parts, etc. It can solve the problems of energy consumption, slow speed, loud noise, etc., and achieve the effect of saving energy and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

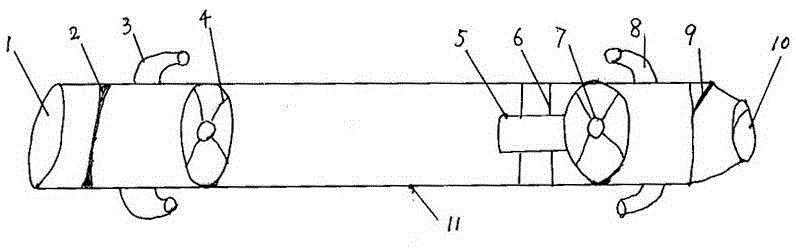

[0014] Embodiment 1, single tube marine water jet propeller: as figure 1 Shown: be provided with a cylindrical spray pipe 11 on the hull outer wall of ship bottom, be provided with water inlet 1 at one end of this pipe, the other end is provided with closed water nozzle 10, near the pipe at one end of water inlet The water inlet valve 2 and the blade water wheel 4 of the hydroelectric generator are respectively arranged in the wall, and the water outlet valve 9 and the electric water spray machine 5 are arranged in sequence in the pipe near the water spray port 10, and the electric water spray machine passes through the bracket 6 Be fixed on the pipe wall of water spray pipe 11, be provided with water wheel blade 7 at the nozzle of water spray machine; Be provided with hydroelectric generator at the bottom of described ship, the rotating shaft of this hydroelectric generator is connected with spray by gear or belt. The rotating shaft of the blade water wheel 4 in the water pip...

Embodiment 2

[0017] Embodiment 2, twin-pipe marine water jet propeller: two such as figure 1 Cylindrical water spray pipe 11, its structure is connected with embodiment 1, and two water spray pipes 11 work simultaneously, just can make boats and ships advance or retreat more rapidly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com