Low-water-resistance submarine

A low water resistance, submarine technology, applied in the direction of underwater ships, ships, underwater operation equipment, etc., can solve problems such as affecting the navigation speed of submarines, and achieve the effects of reducing water resistance, reducing noise, and speeding up the navigation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

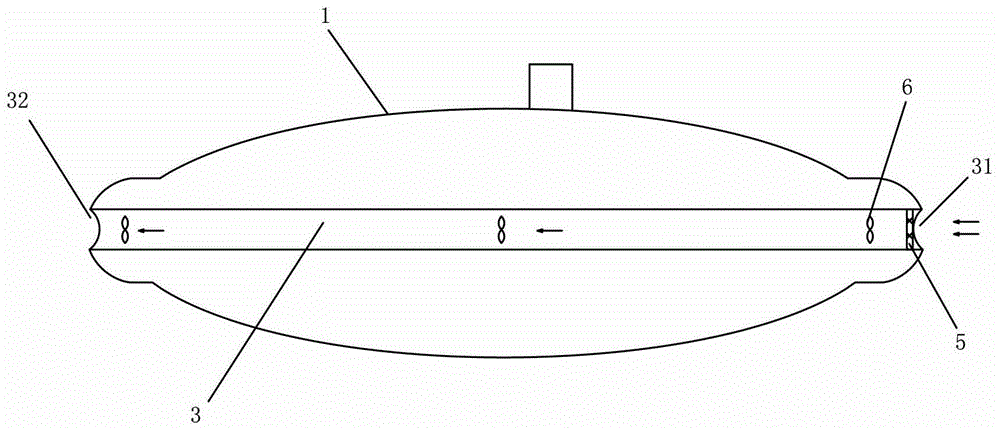

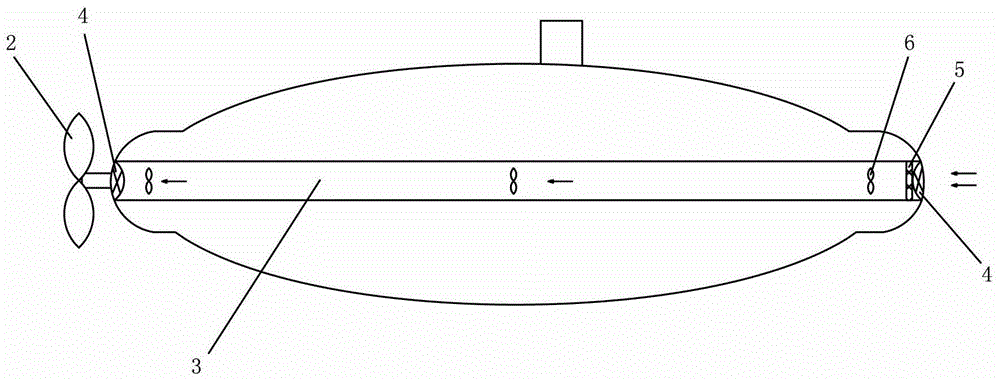

[0019] Such as figure 1 As shown, a low water resistance submarine includes a hull 1, which is characterized in that, the hull 1 is provided with a drainage channel 3 along its length extension direction, the drainage channel 3 is arranged in the middle part of the hull 1, and the drainage channel 3 is two The ends are water inlet 31 and water outlet 32 respectively, and water inlet 31 and water outlet 32 are arranged at the front end and rear end of hull 1 respectively.

[0020] In order to prevent larger impurities in the seawater from clogging the drainage channel, the water inlet 31 of the drainage channel 3 is also provided with a filter 5 .

[0021] In order to form a better negative pressure zone in the drainage channel 3 and accelerate the drainage of seawater, one or several water diversion propellers 6 are arranged on the drainage channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com