Blade

A blade and auxiliary blade technology, applied in the field of fan blade design, can solve the problems of high cost, frequent activation of the speed-limiting mechanism, large loss, etc., and achieve the effects of improving stress, increasing resistance, and reducing wind speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

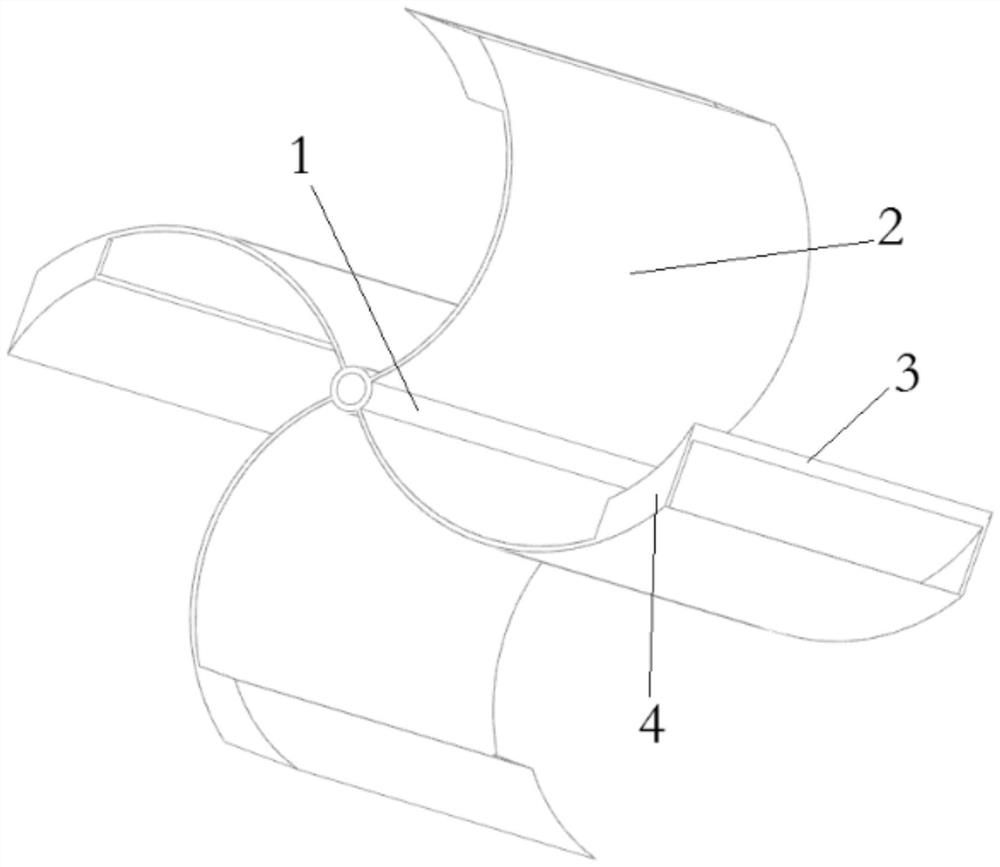

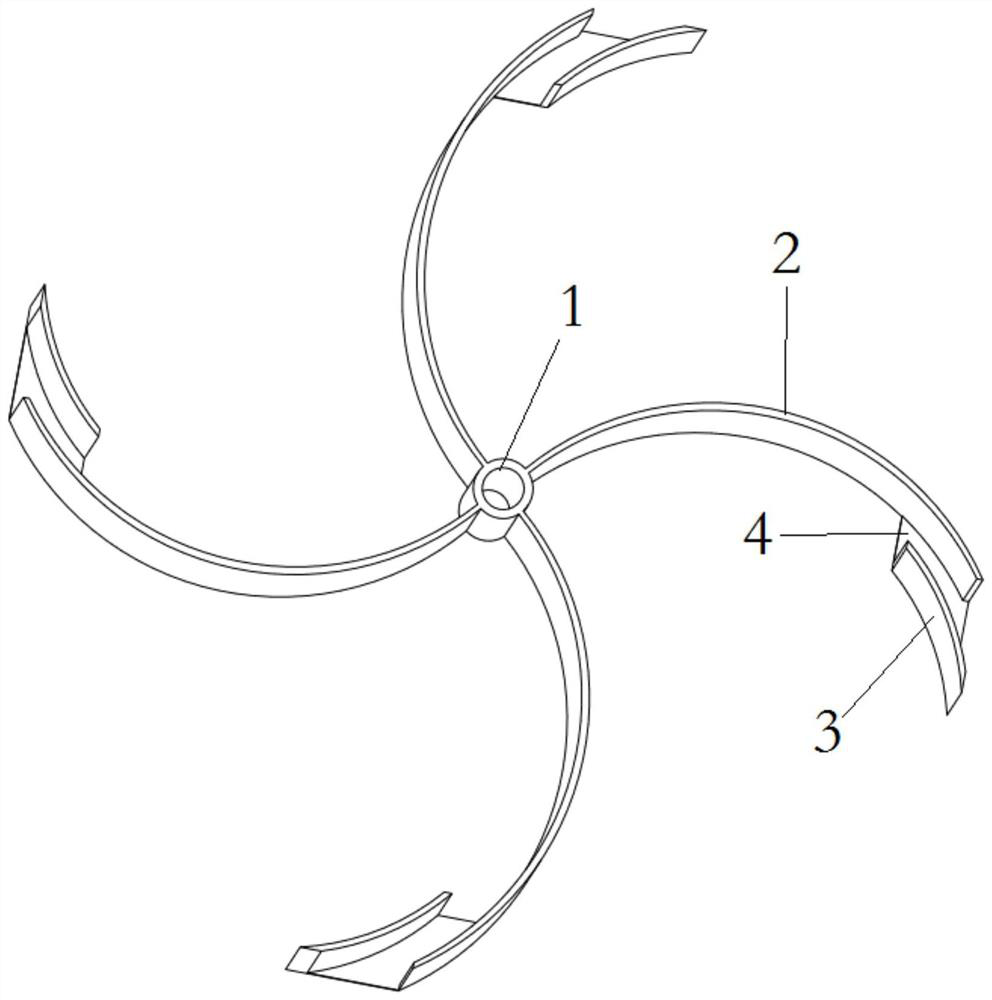

[0024] like figure 1 and figure 2 As shown, a blade includes a mandrel 1 and a sheet body 2, the sheet body 2 is evenly distributed around the mandrel 1 in the circumferential direction and the tail end of the sheet body is fixedly connected to the mandrel 1, and the head end of the sheet body 2 is provided with Auxiliary blade 3 , the shape of which is the equidistant surface of the corresponding sheet body; both ends of the auxiliary blade are fixedly connected to the sheet body through bracket 4 .

Embodiment 2

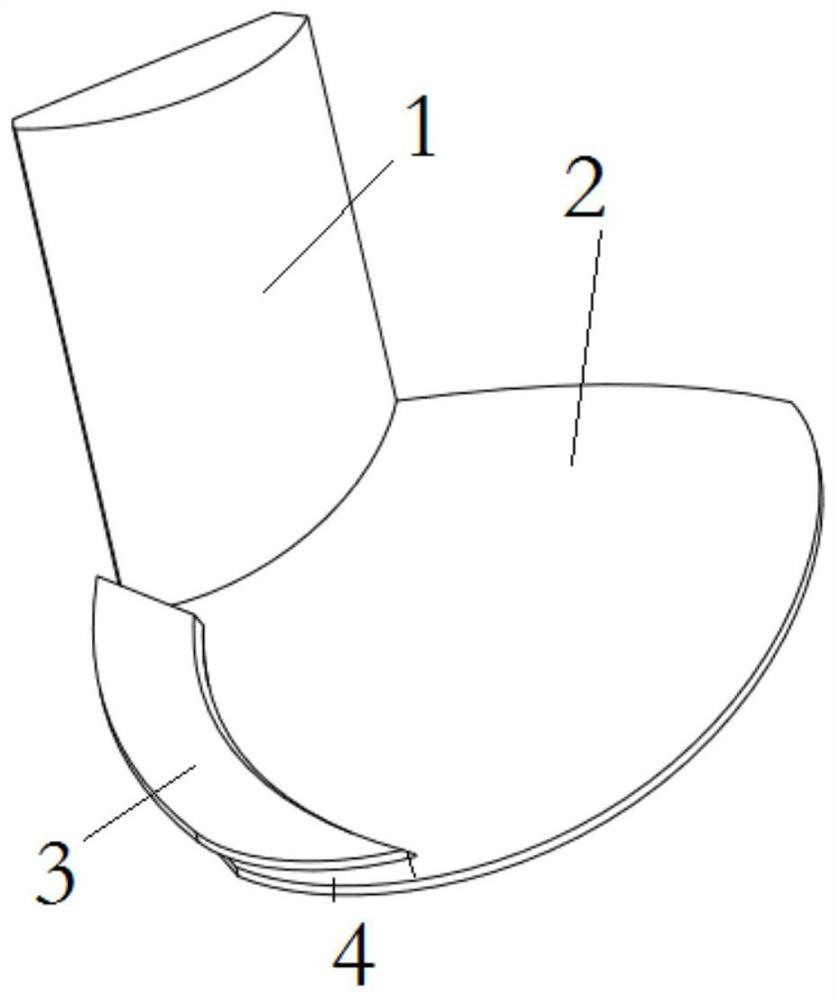

[0026] like image 3 As shown, a blade includes a mandrel 1 and a sheet body 2, the sheet body 2 is evenly distributed around the mandrel 1 in the circumferential direction and the tail end of the sheet body is fixedly connected to the mandrel 1, and one side of the sheet body 2 is provided with There are auxiliary blades 3, and the shape of the auxiliary blades 3 is the equidistant surface of the corresponding sheet body part; the two ends of the auxiliary blades are fixedly connected with the sheet body through the bracket 4.

Embodiment 3

[0028] In this embodiment, the stand is an electric folding stand. The main function of using the electric folding bracket is to open the auxiliary blade when needed to form a channel with the sheet body, and to form a folded shape between the auxiliary blade and the sheet body when not needed to reduce resistance.

[0029] Figure 4 The structure of one type of electric bracket is shown. Specifically, the bottom and top of the two brackets 4 are respectively hinged with the sheet body and the auxiliary blade 3, and the sheet body is respectively provided with a The fixed pulley 5, the mandrel 1 is provided with a forward and reverse motor 6, and the rotating shaft is provided with a wire wheel 7, and the wire wheel is provided with a winding wire, and the two ends of the winding wire are outgoing, and one end of the outgoing wire is fixed to the auxiliary blade through a fixed pulley connection, the other end of the outgoing line is fixedly connected to the auxiliary blade t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com