Dipulse engine with integrated propellent twining structure and preparation method

A dual-pulse and engine technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as poor manufacturability, accelerated one-pulse grain aging, and large negative mass, so as to reduce negative mass and increase the filling ratio , the effect of reducing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

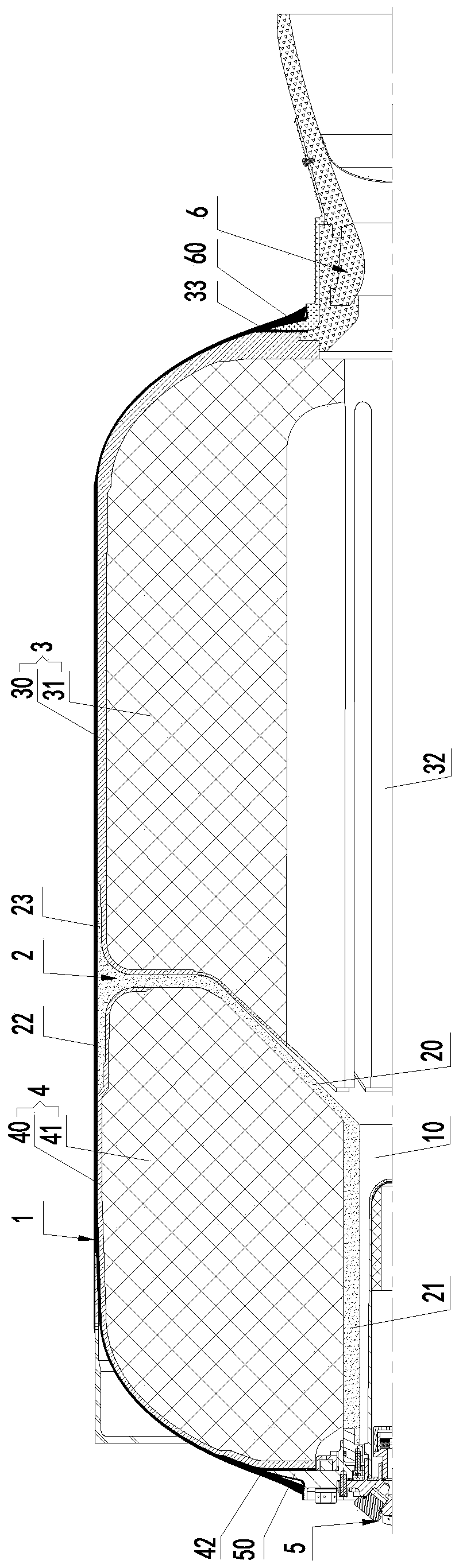

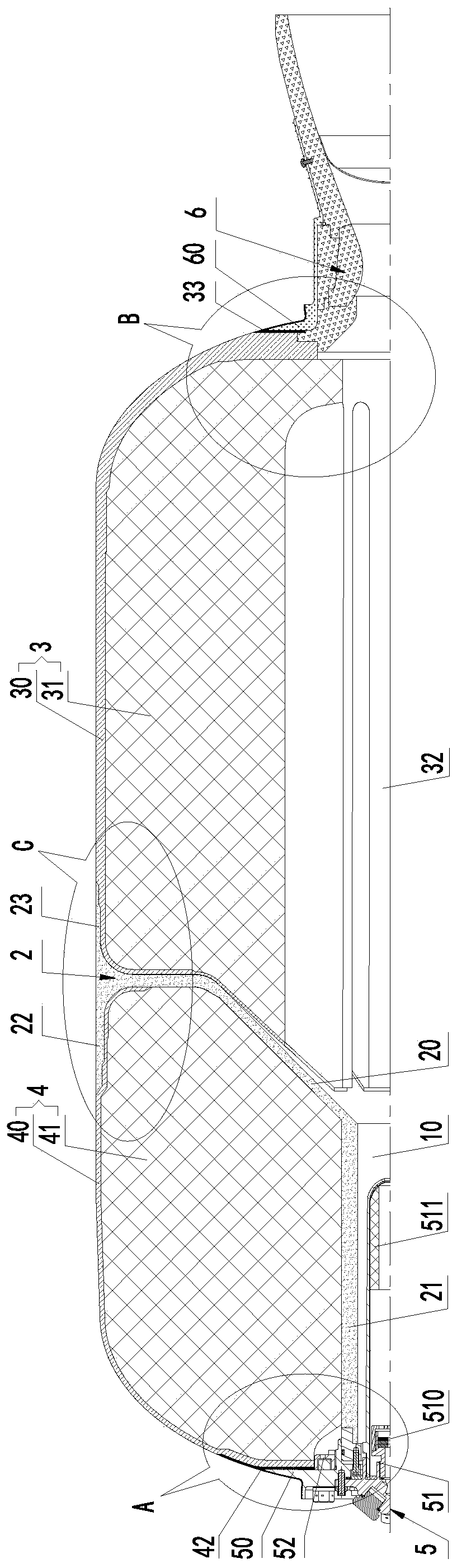

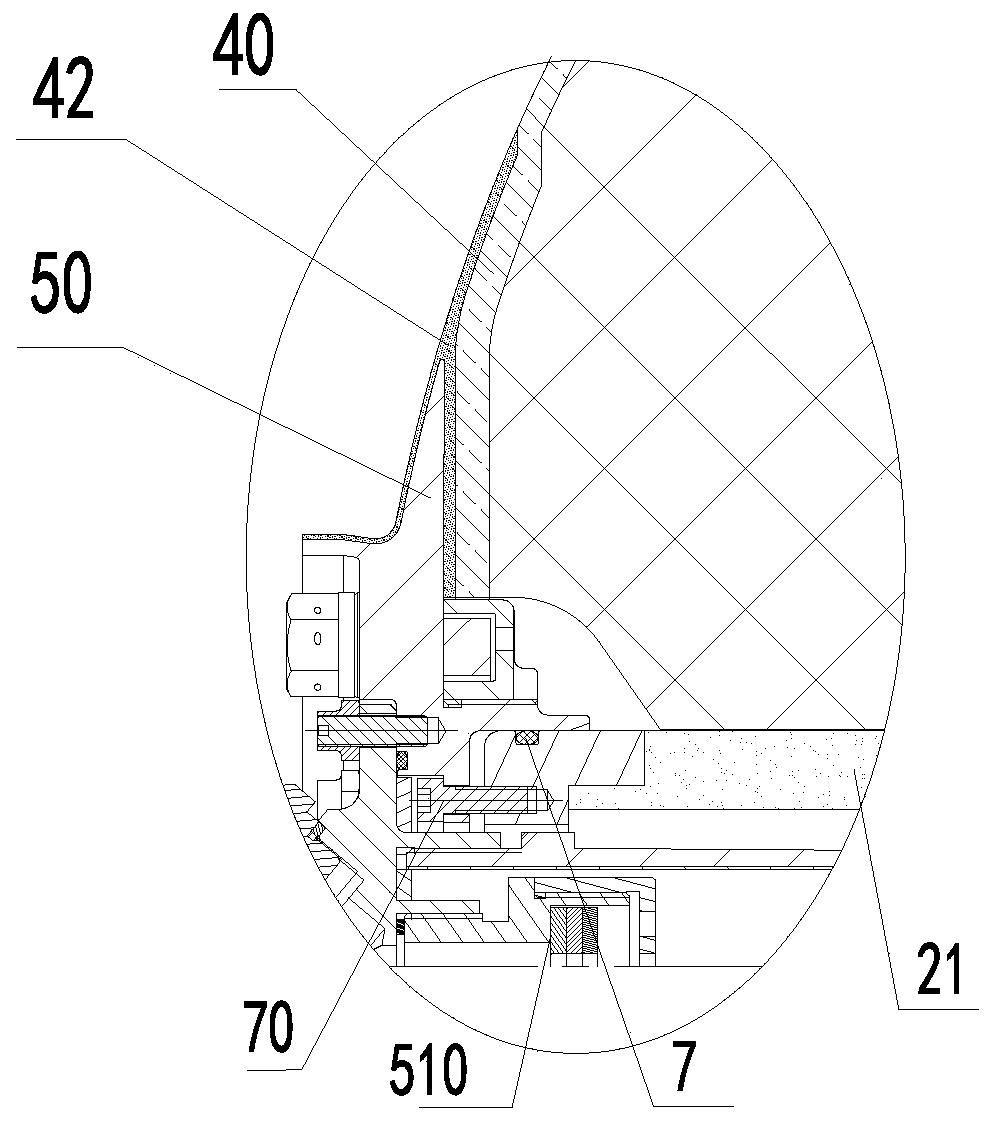

[0041] see figure 1 As shown, the embodiment of the present invention provides a double-pulse engine with a drug winding integrated structure, which includes a combustion chamber housing 1, a soft partition 2, a first pulse grain assembly 3, and a second pulse grain assembly 4. Ignition device 5 and nozzle 6;

[0042] Both ends of the combustion chamber housing 1 are respectively provided with a front opening and a rear opening;

[0043] see figure 1 As shown, the soft interlayer 2 is located in the combustion chamber housing 1, the soft interlayer 2 includes a first segment 20 and a second segment 21, one end of the first segment 20 is bonded to the inner wall of the combustion chamber housing 1, and the first The other end of the section 20 extends toward the front opening and forms a second section 21. The soft partition 2 divides the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com