Patents

Literature

46results about How to "Avoid lifespan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

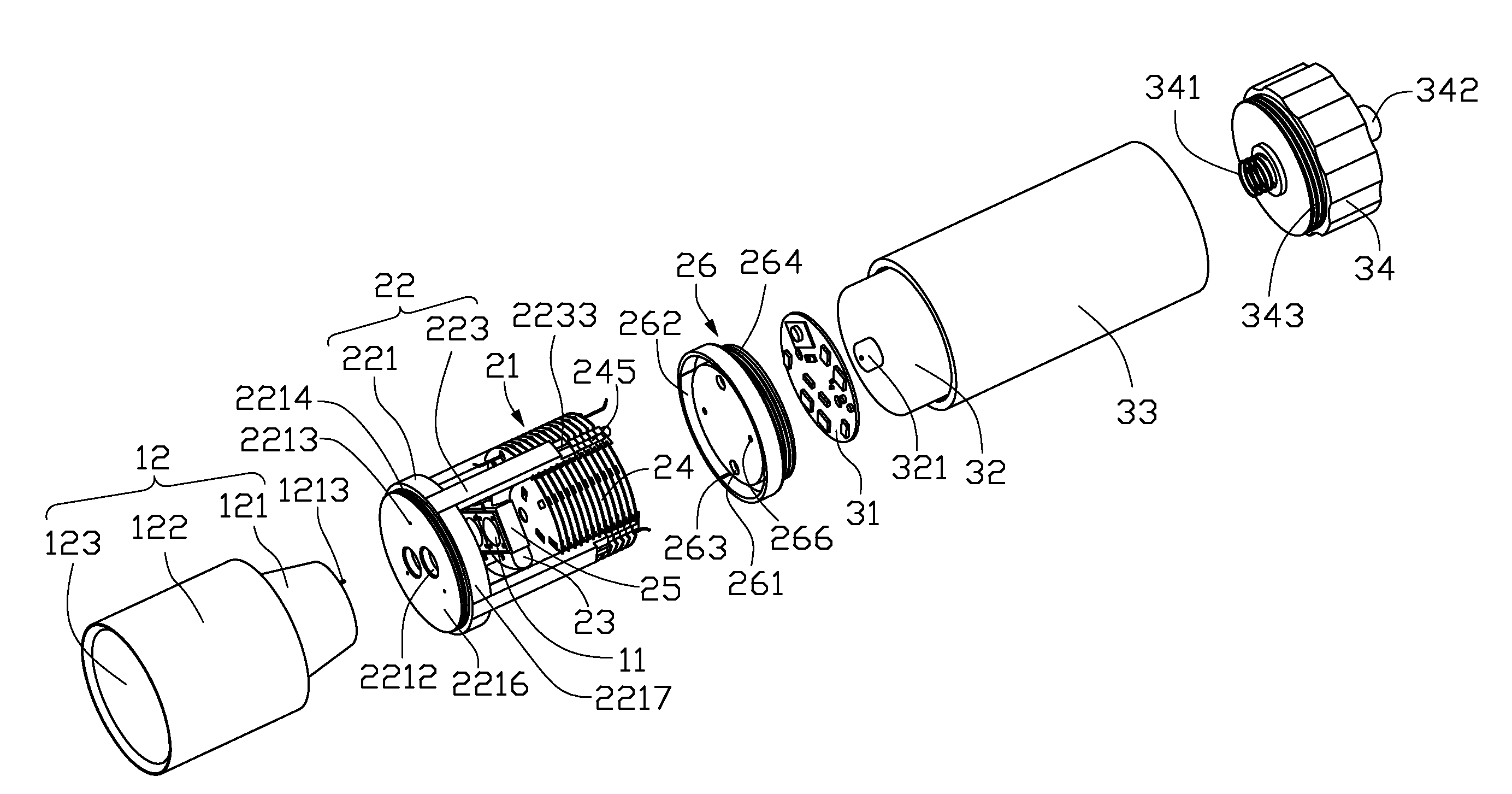

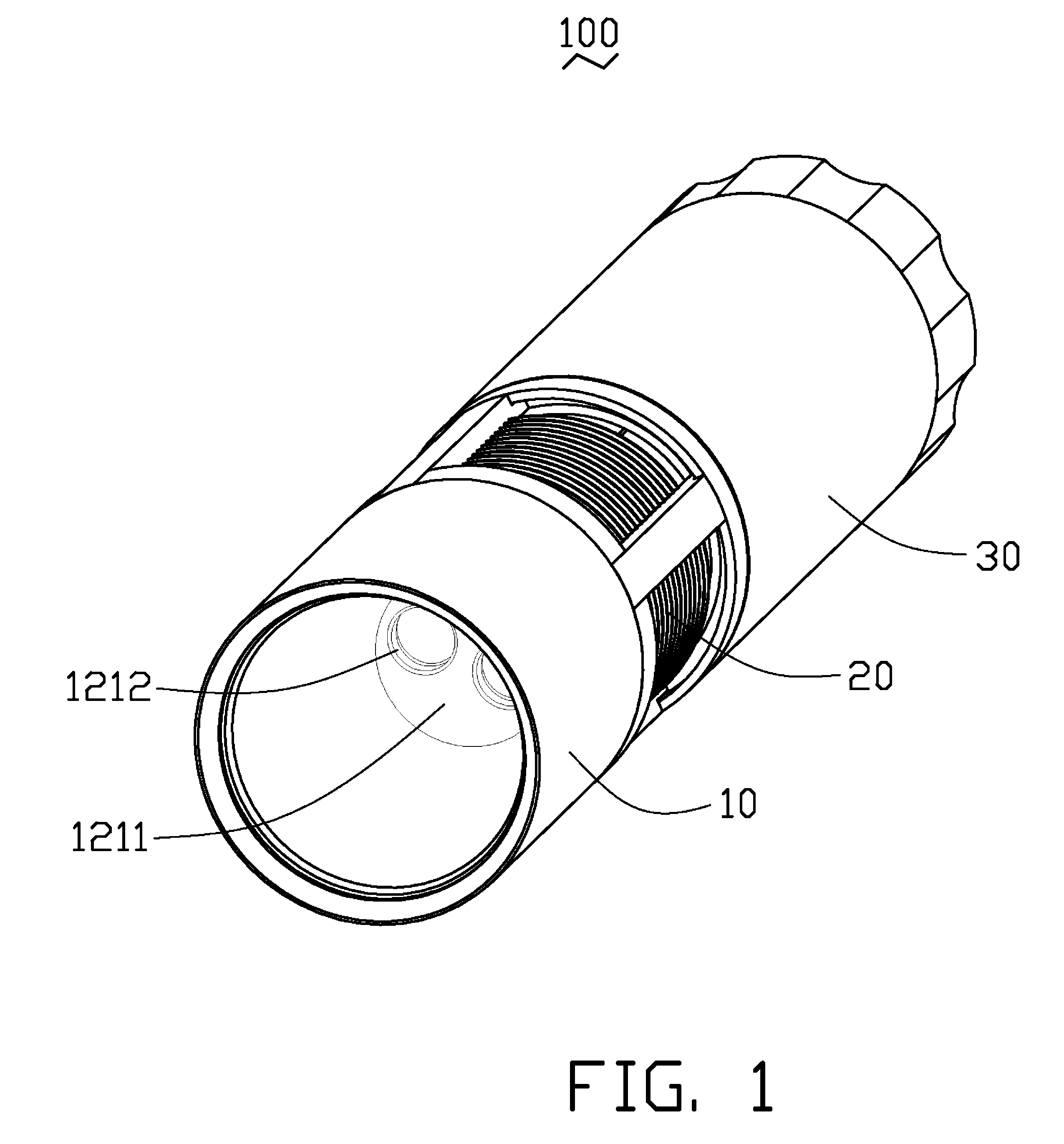

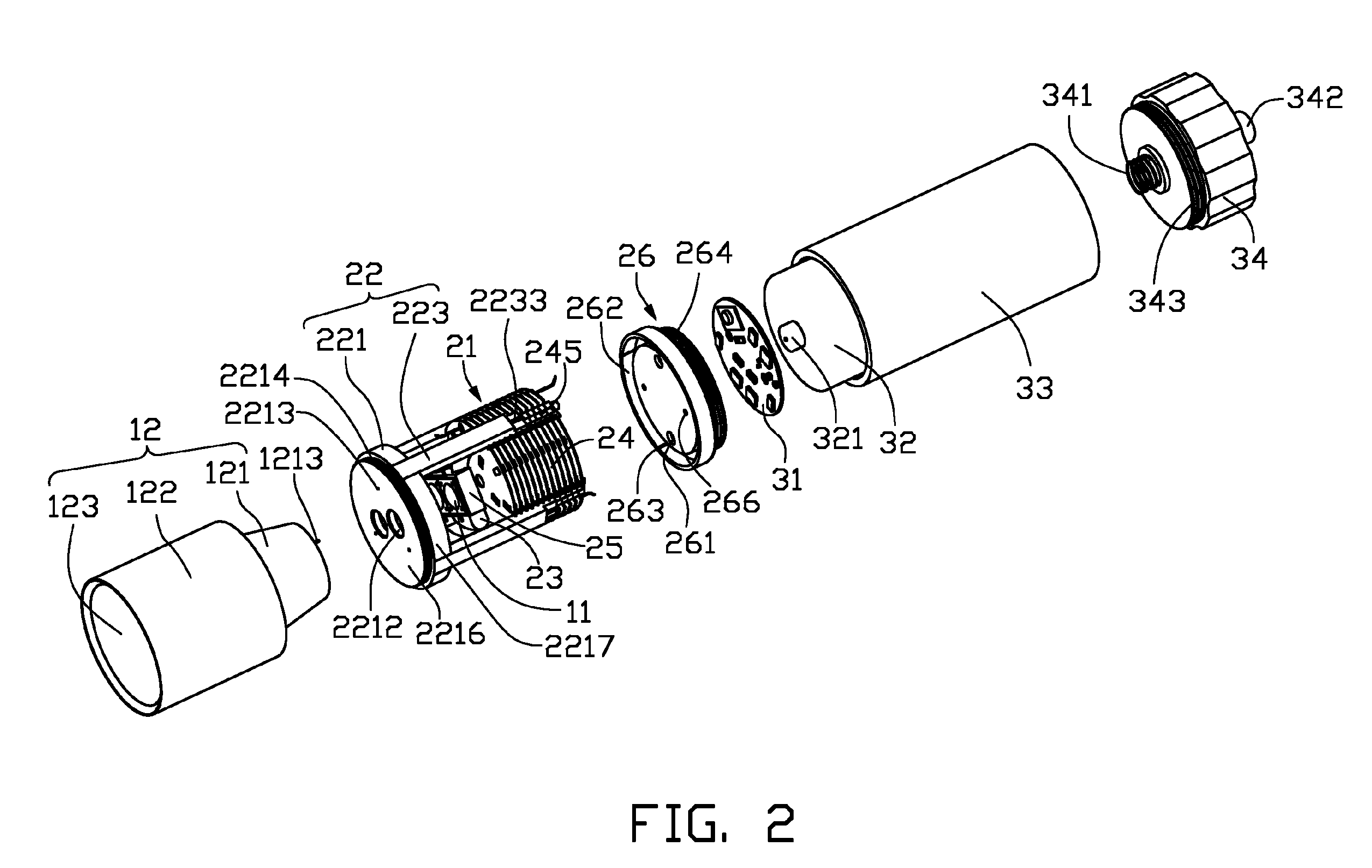

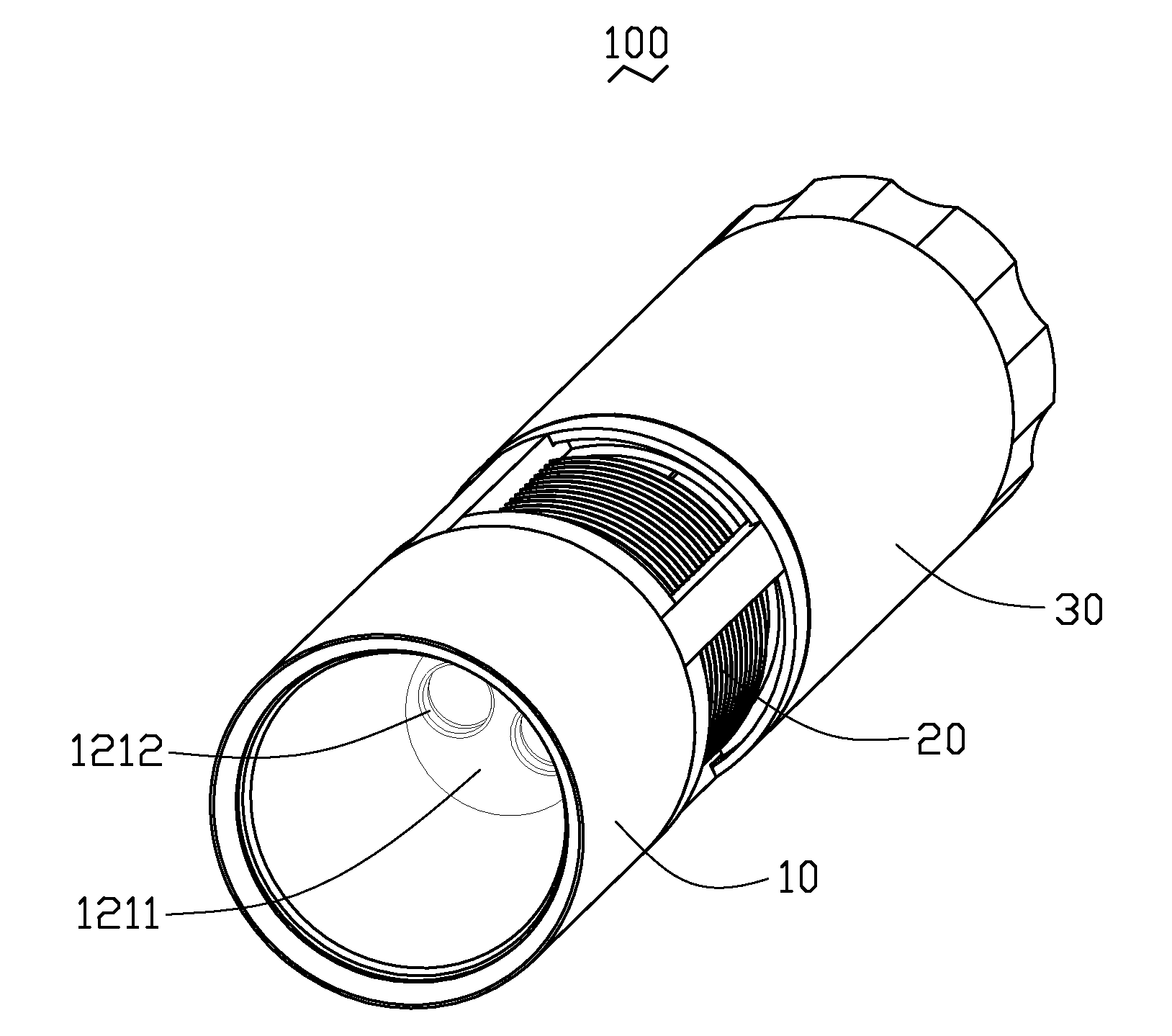

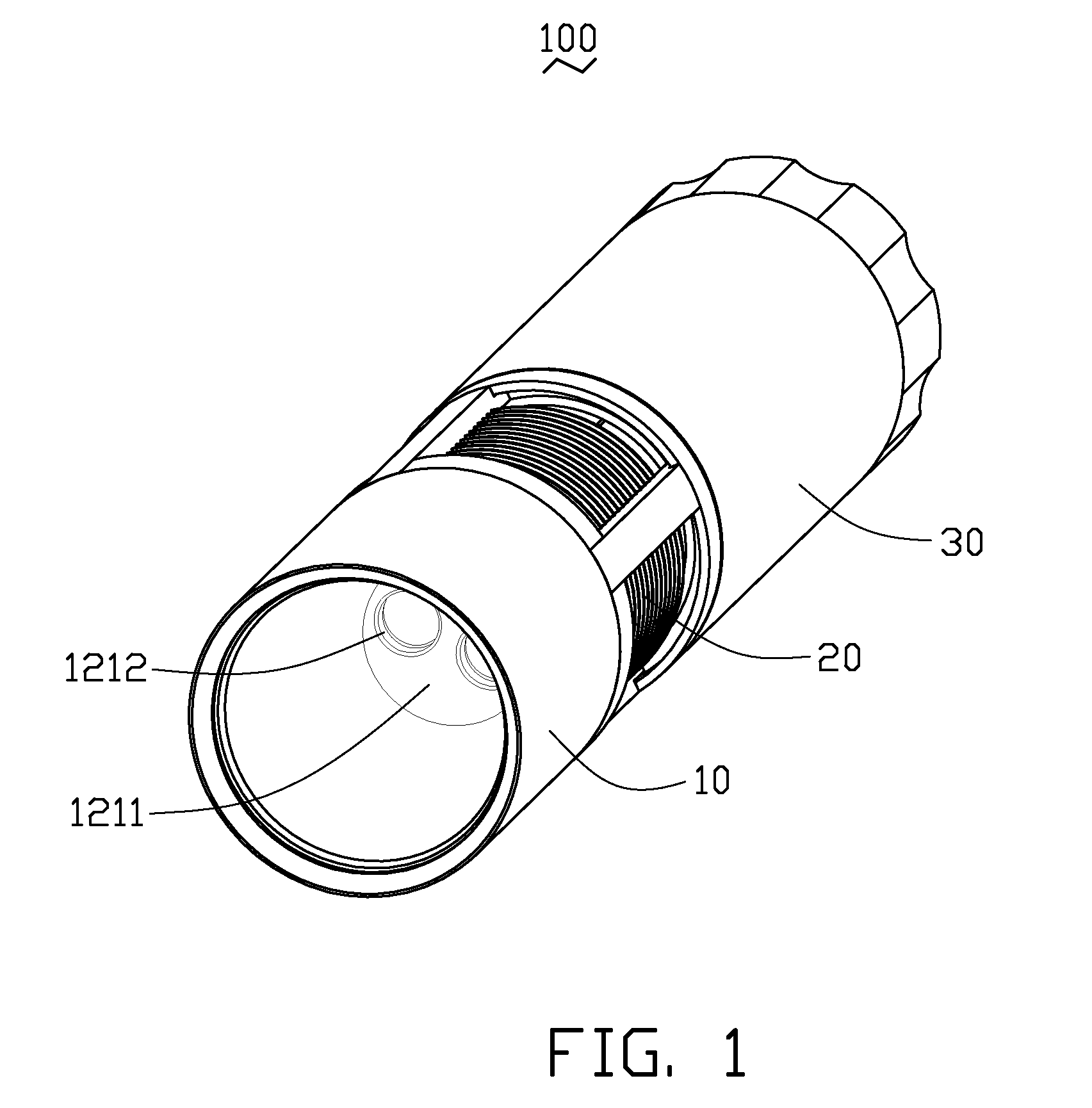

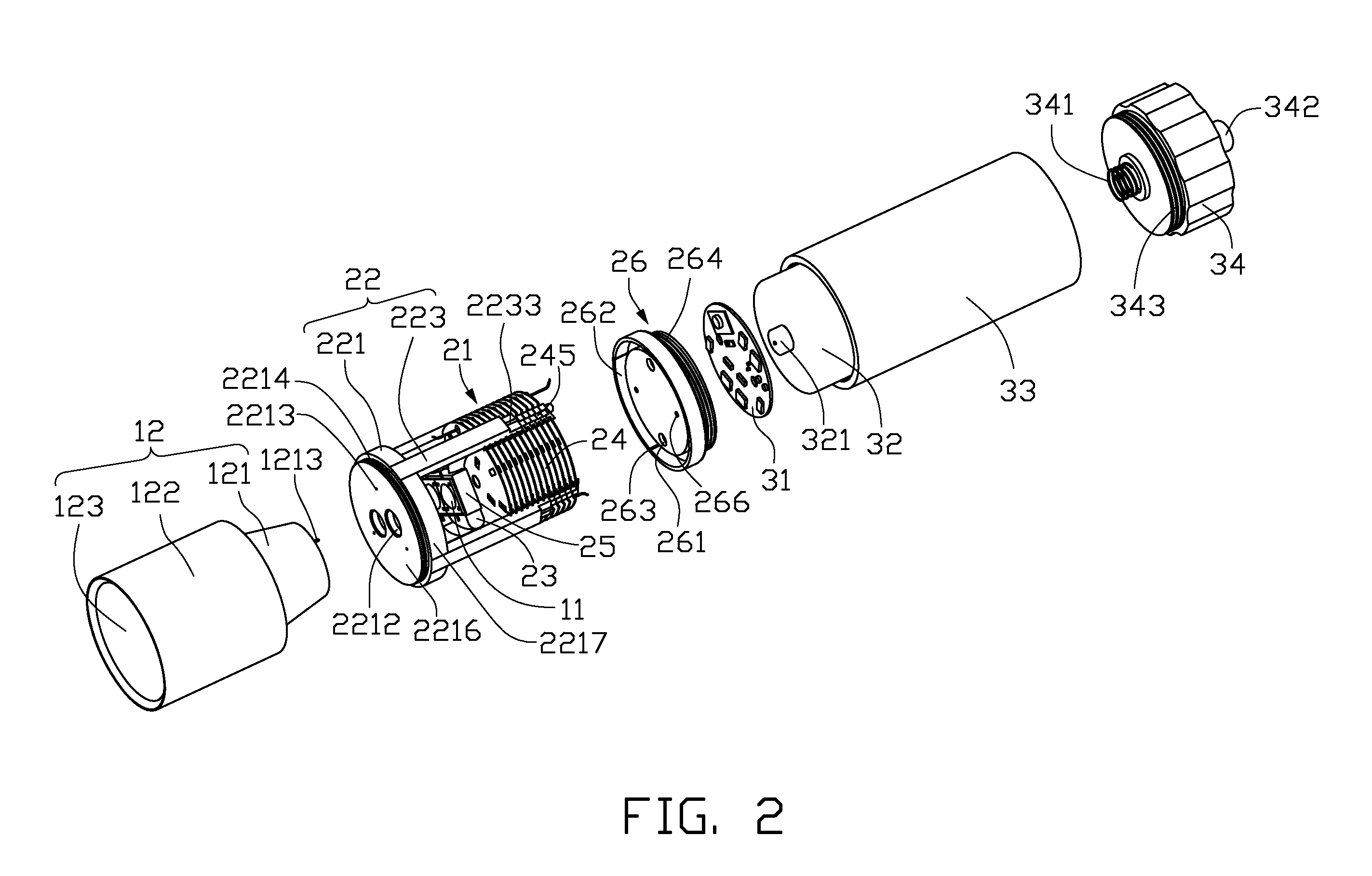

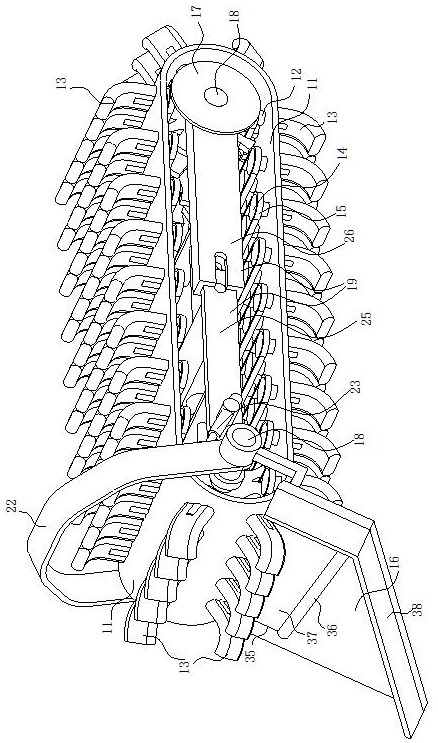

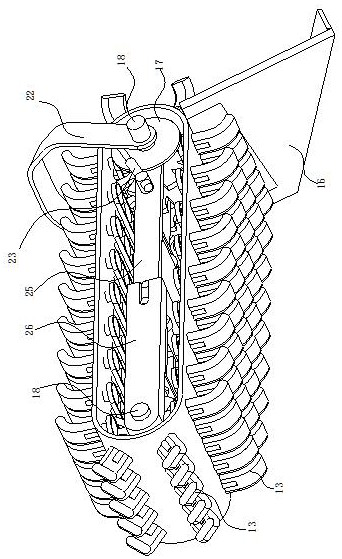

LED illumination device and light engine thereof

InactiveUS7841753B2Efficient heat dissipationAvoid brightnessPoint-like light sourceLighting support devicesElectricityEvaporation

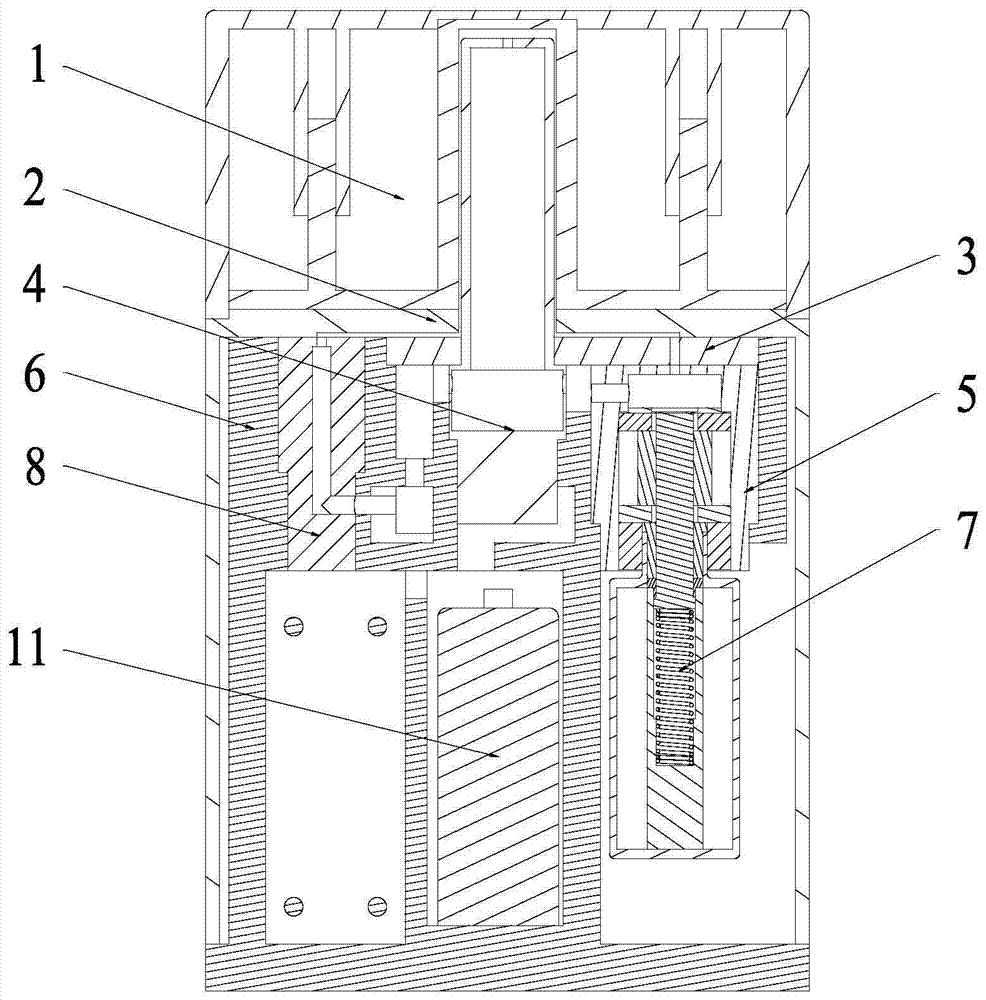

An LED illumination device includes an optical section at a front end thereof, an electrical section at a rear end thereof, and a heat dissipation section between the optical section and the electrical section. The optical section includes a plurality of LEDs electrically connecting with the electrical section, and a light output housing around the LEDs. The heat dissipation section includes a plurality of L-shaped heat pipes, a heat sink and a mounting seat. Each of the heat pipes includes an evaporation section and a condensation section substantially perpendicular thereto. The condensation sections of the heat pipes are received in the heat sink. The mounting seat attaches to the evaporation sections of the heat pipes. The LEDs thermally connect with evaporation sections via the mounting seat.

Owner:HON HAI PRECISION IND CO LTD

LED illumination device and light engine thereof

InactiveUS20090237933A1Efficient heat dissipationAvoid brightnessLighting support devicesPoint-like light sourceElectricityEvaporation

An LED illumination device includes an optical section at a front end thereof, an electrical section at a rear end thereof, and a heat dissipation section between the optical section and the electrical section. The optical section includes a plurality of LEDs electrically connecting with the electrical section, and a light output housing around the LEDs. The heat dissipation section includes a plurality of L-shaped heat pipes, a heat sink and a mounting seat. Each of the heat pipes includes an evaporation section and a condensation section substantially perpendicular thereto. The condensation sections of the heat pipes are received in the heat sink. The mounting seat attaches to the evaporation sections of the heat pipes. The LEDs thermally connect with evaporation sections via the mounting seat.

Owner:HON HAI PRECISION IND CO LTD

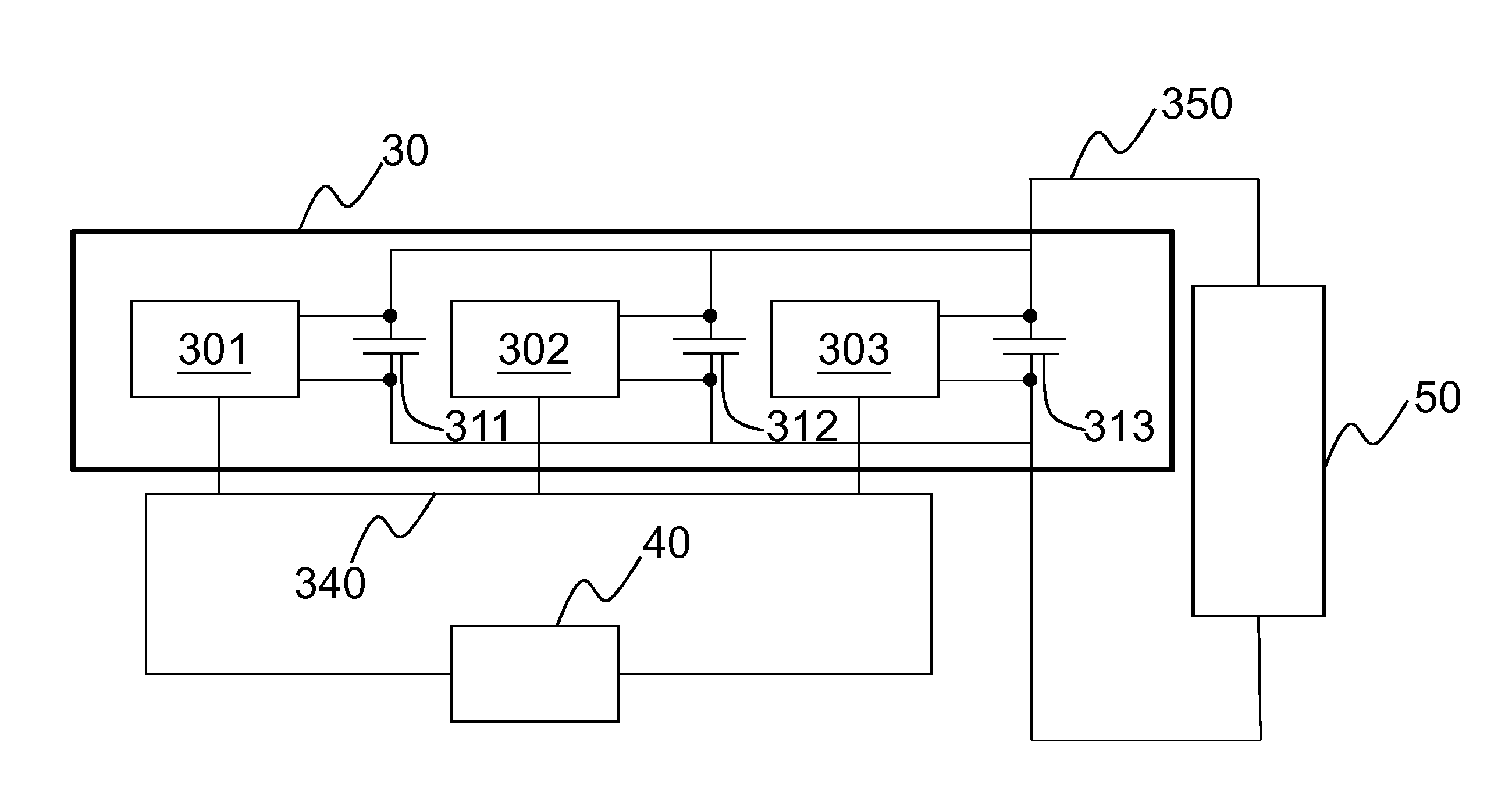

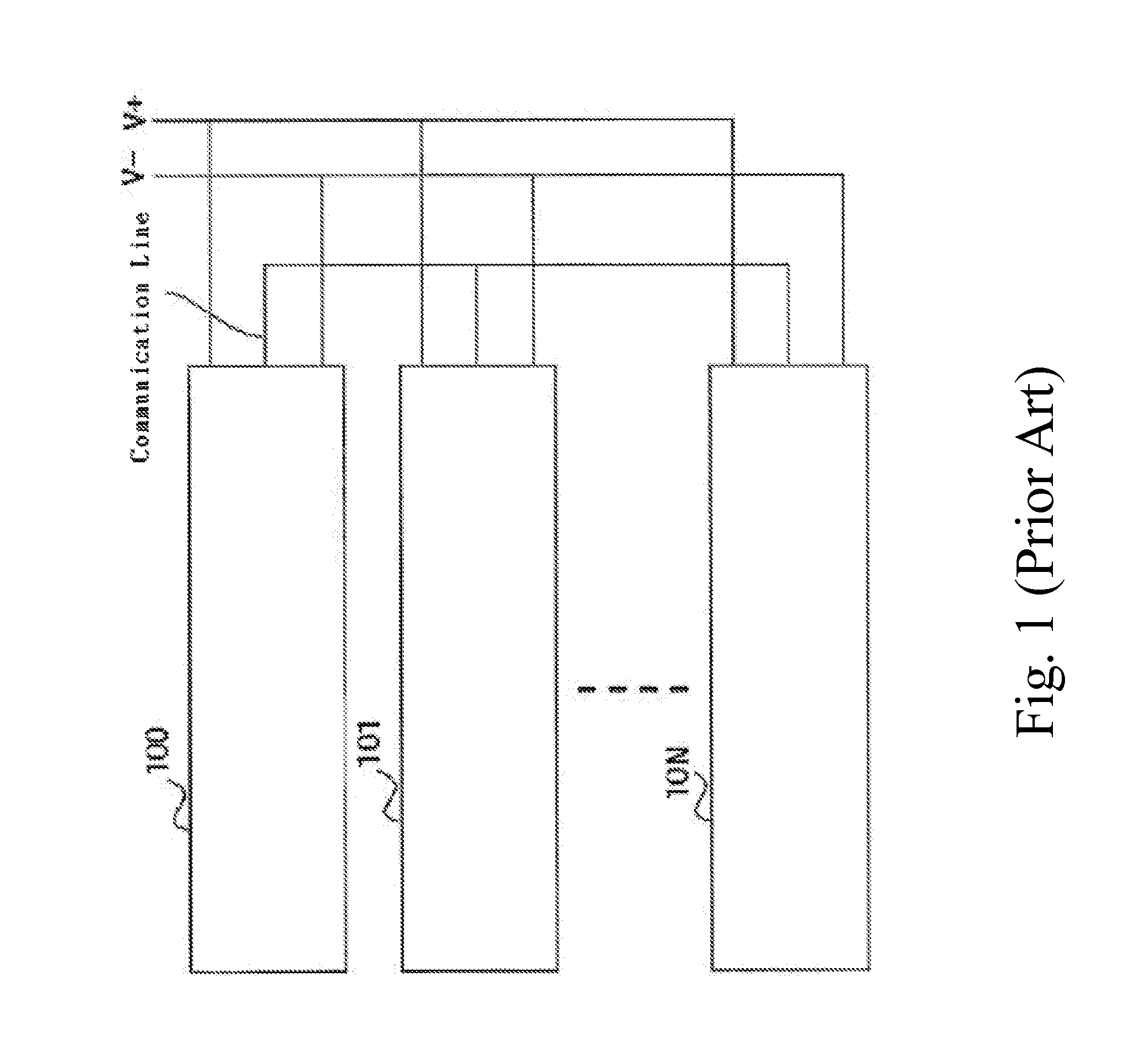

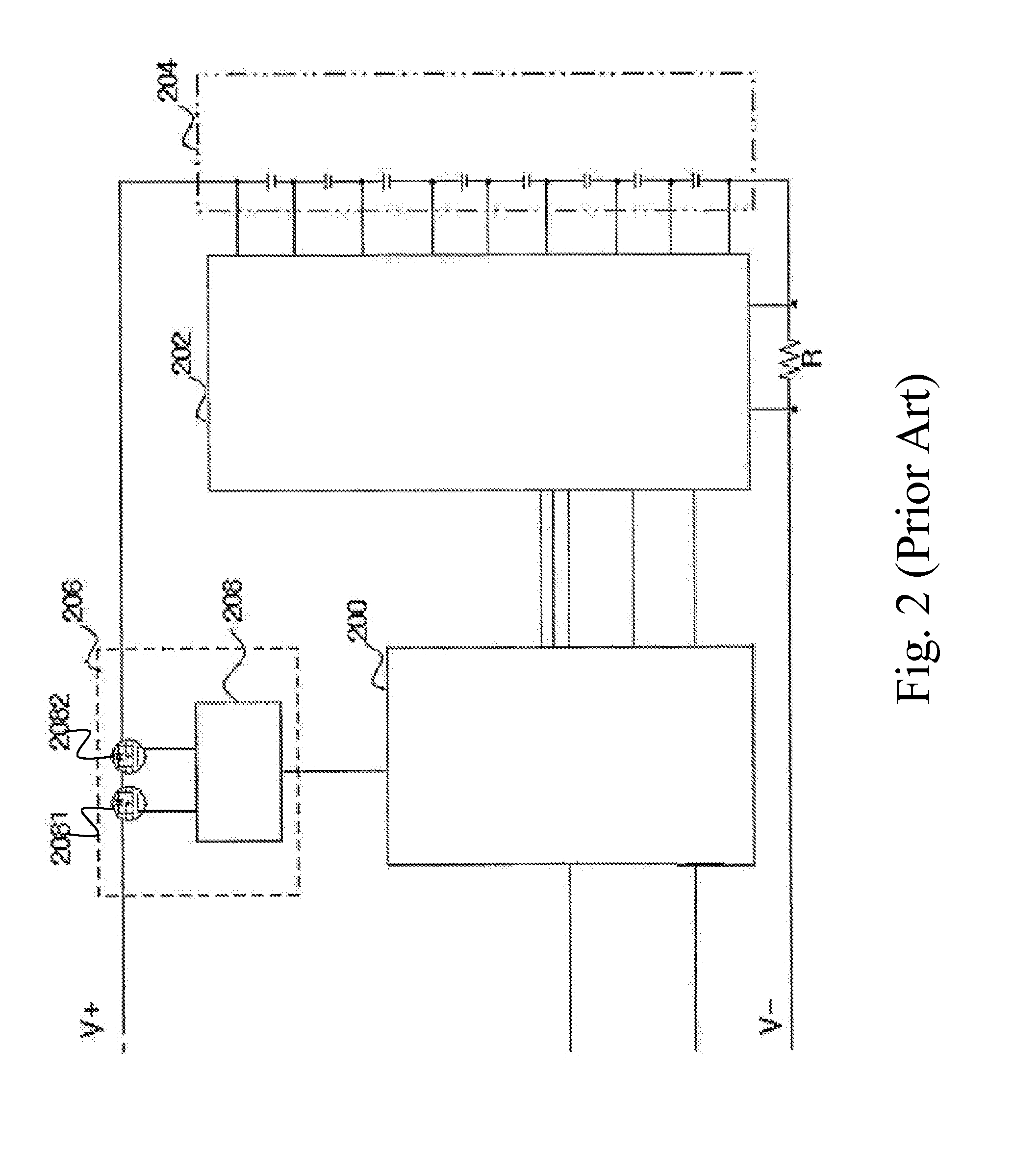

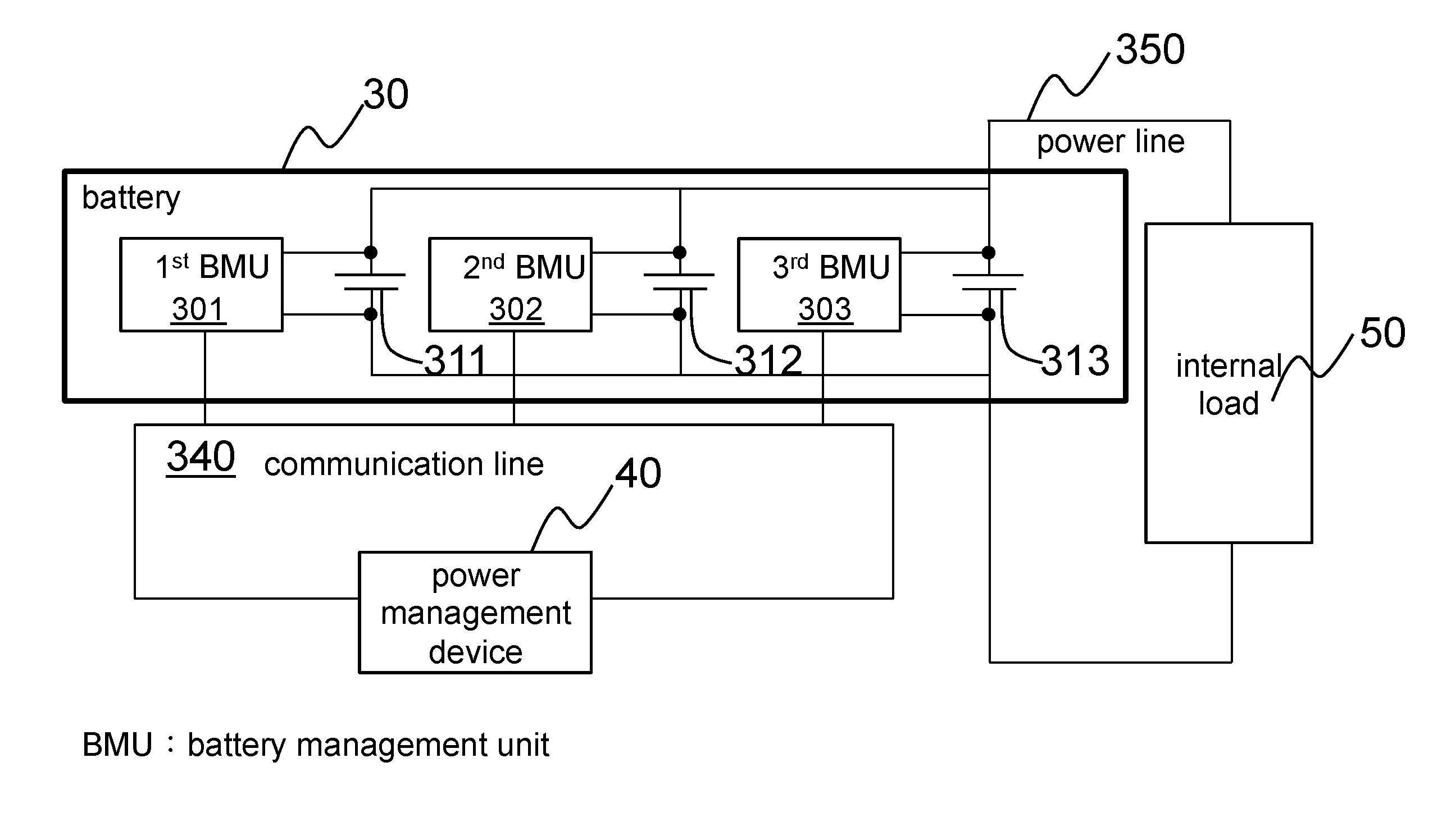

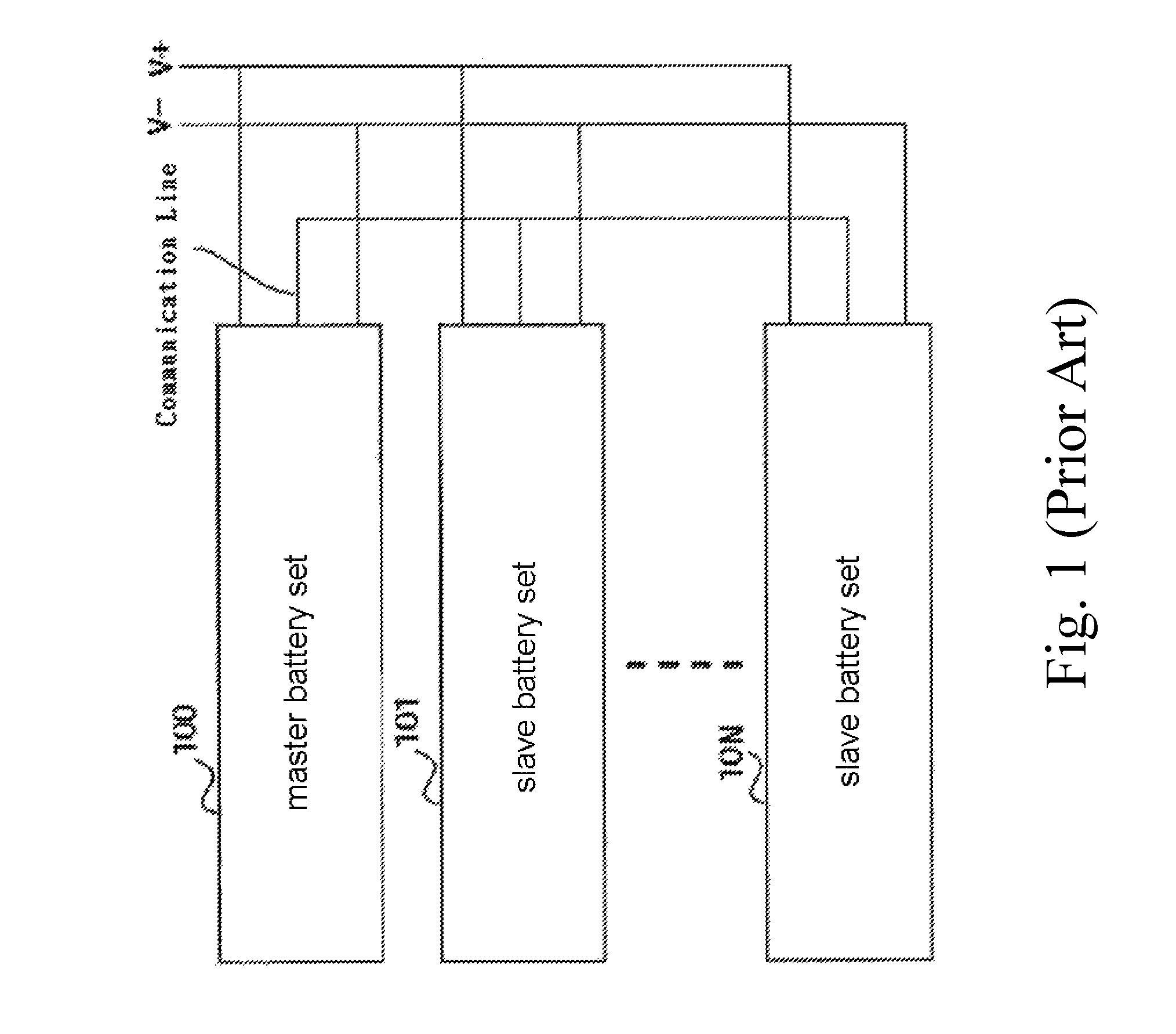

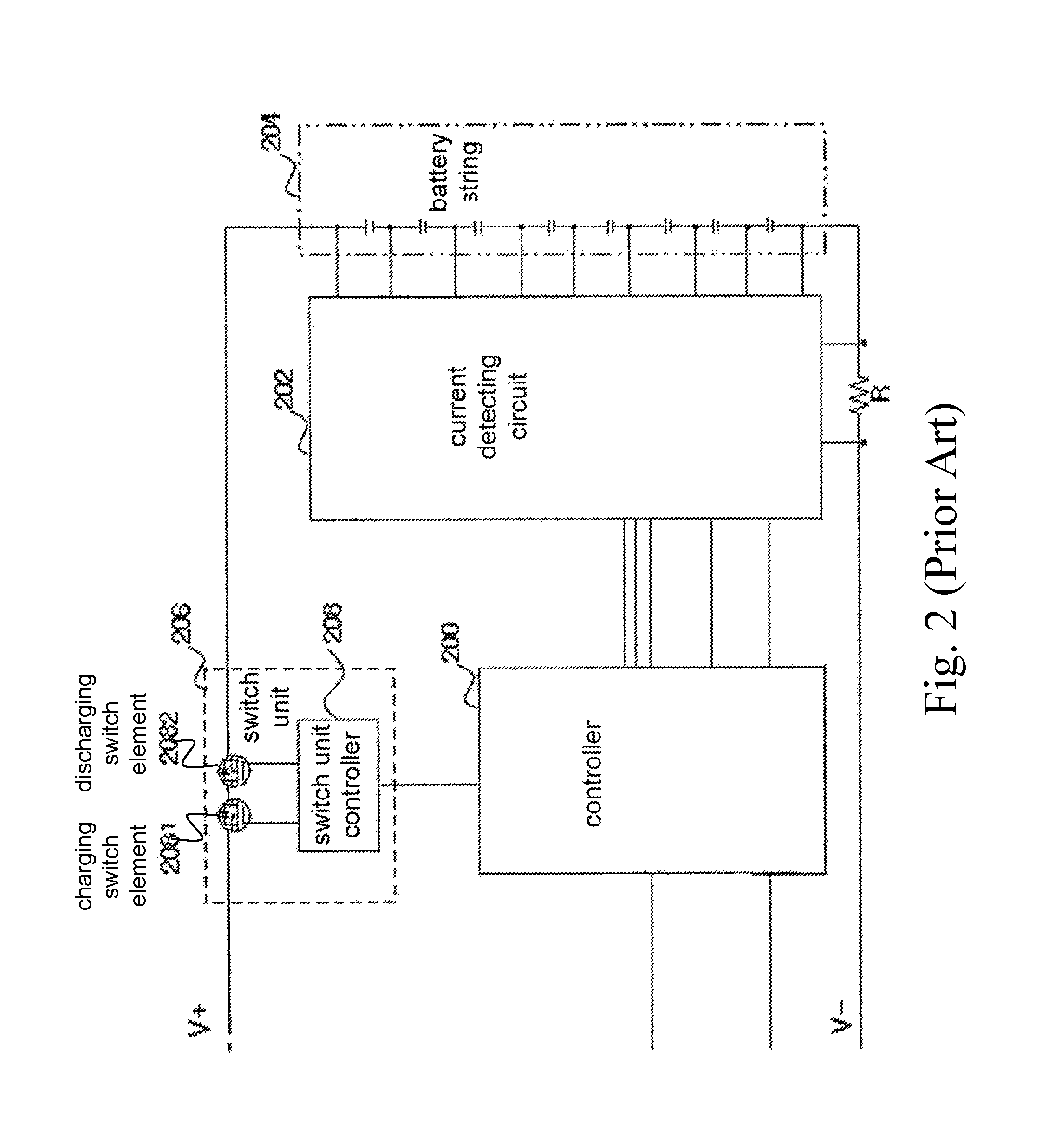

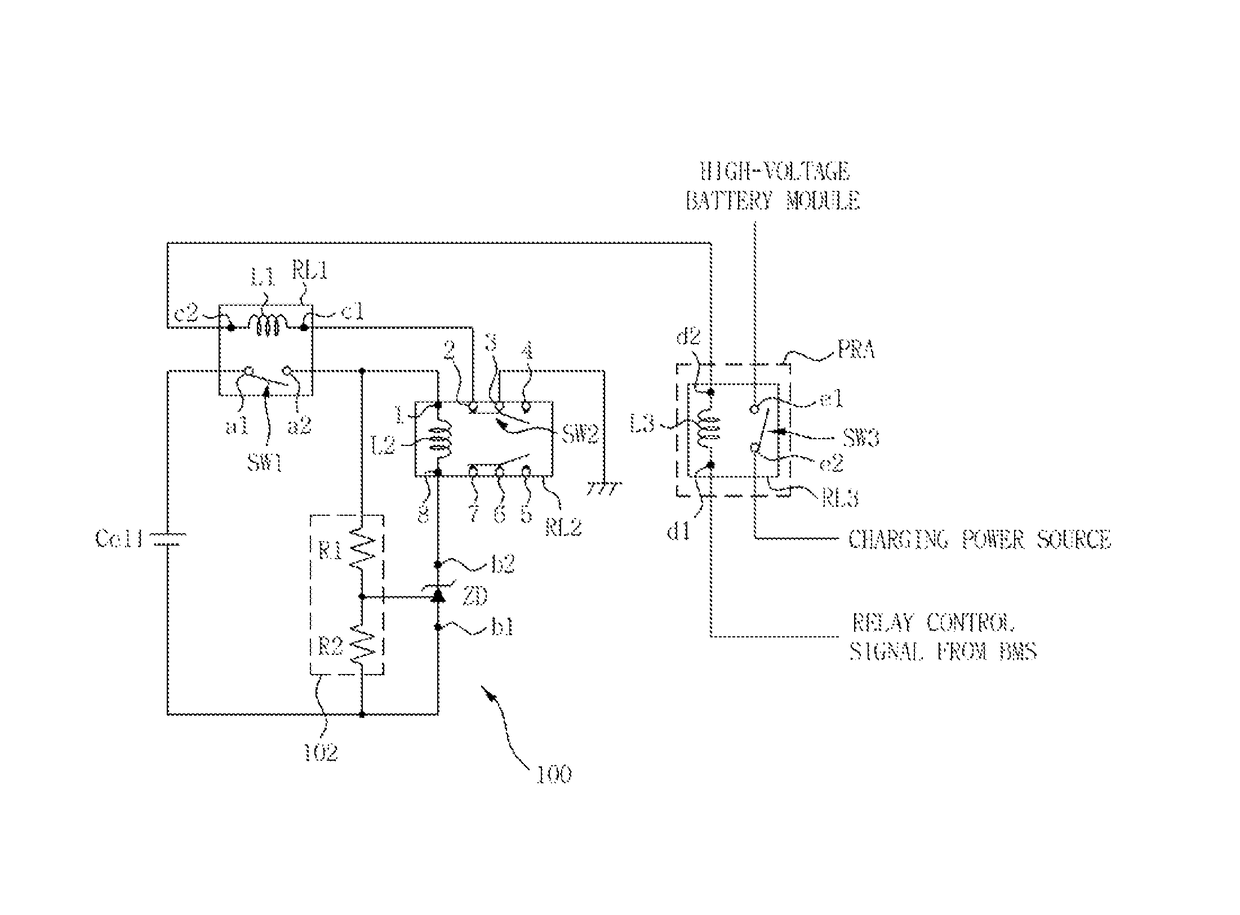

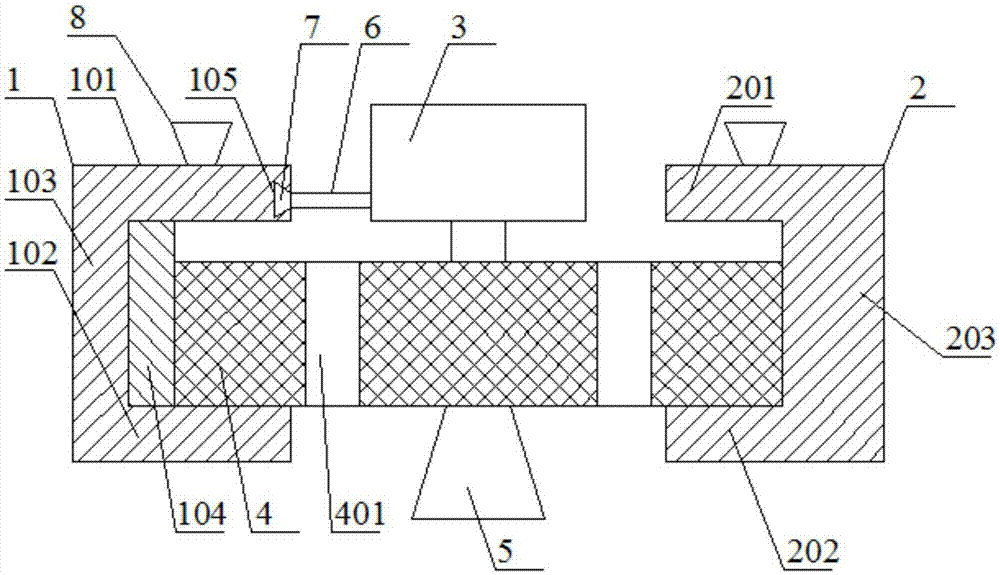

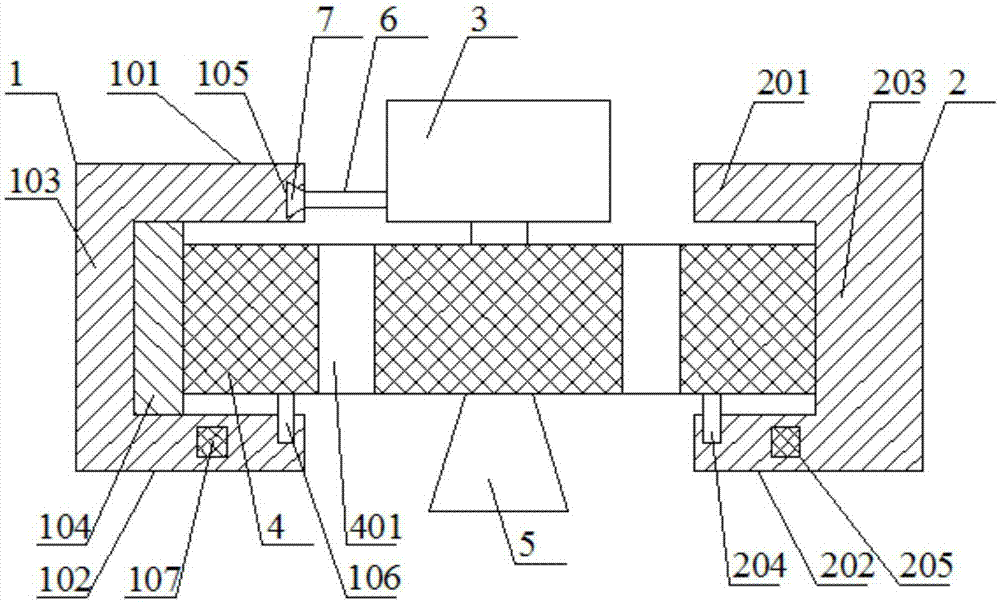

Master-slave type battery managemaent system for accurate capacity guage of battery pack

ActiveUS20150221993A1Avoid decrease of lifetimeEasy data collectionCells structural combinationBatteriesBattery management systemsRechargeable cell

A master-slave type battery management system for accurate capacity gauge of battery packs is disclosed. It includes several battery management units linked to each other via a communication line. Each battery management unit is linked to a specified rechargeable battery set to manage the specified rechargeable battery set, detect a physical measurement data from the specified rechargeable battery set and calculates battery set capacity related value based on the physical measurement data. Each battery management unit has a unique battery ID. By assigning a battery management unit having a specified battery ID as a master battery management unit, the rest battery management units become slave battery management units. Each slave battery management unit sends the physical measurement data and battery set capacity related value to the master battery management unit via the communication line. The master battery management unit is in charge of calculating related values and transmitting them.

Owner:HYCON TECH

Master-slave type battery management system for accurate capacity guage of battery pack

ActiveUS9431684B2Avoid lifespanEasy data collectionBatteries circuit arrangementsCells structural combinationManagement unitElectrical battery

A master-slave type battery management system for accurate capacity gauge of battery packs is disclosed. It includes several battery management units linked to each other via a communication line. Each battery management unit is linked to a specified rechargeable battery set to manage the specified rechargeable battery set, detect a physical measurement data from the specified rechargeable battery set and calculates battery set capacity related value based on the physical measurement data. Each battery management unit has a unique battery ID. By assigning a battery management unit having a specified battery ID as a master battery management unit, the rest battery management units become slave battery management units. Each slave battery management unit sends the physical measurement data and battery set capacity related value to the master battery management unit via the communication line. The master battery management unit is in charge of calculating related values and transmitting them.

Owner:HYCON TECH

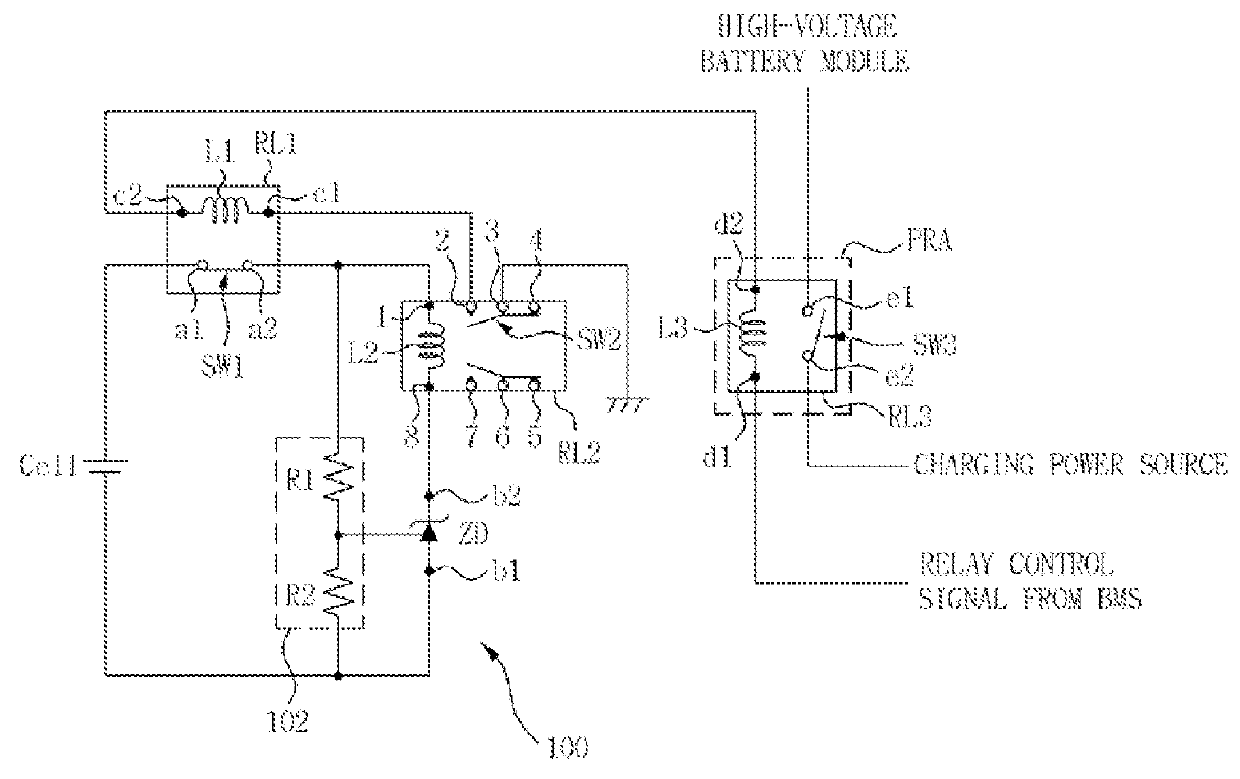

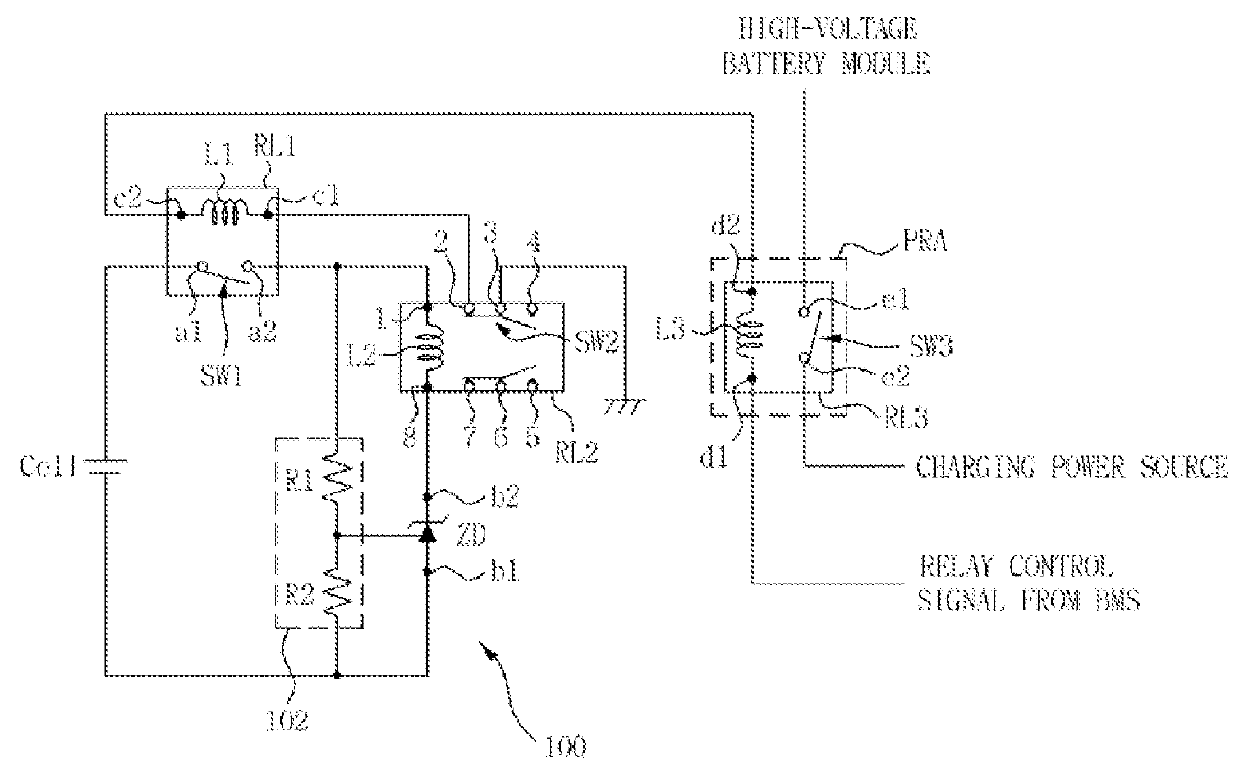

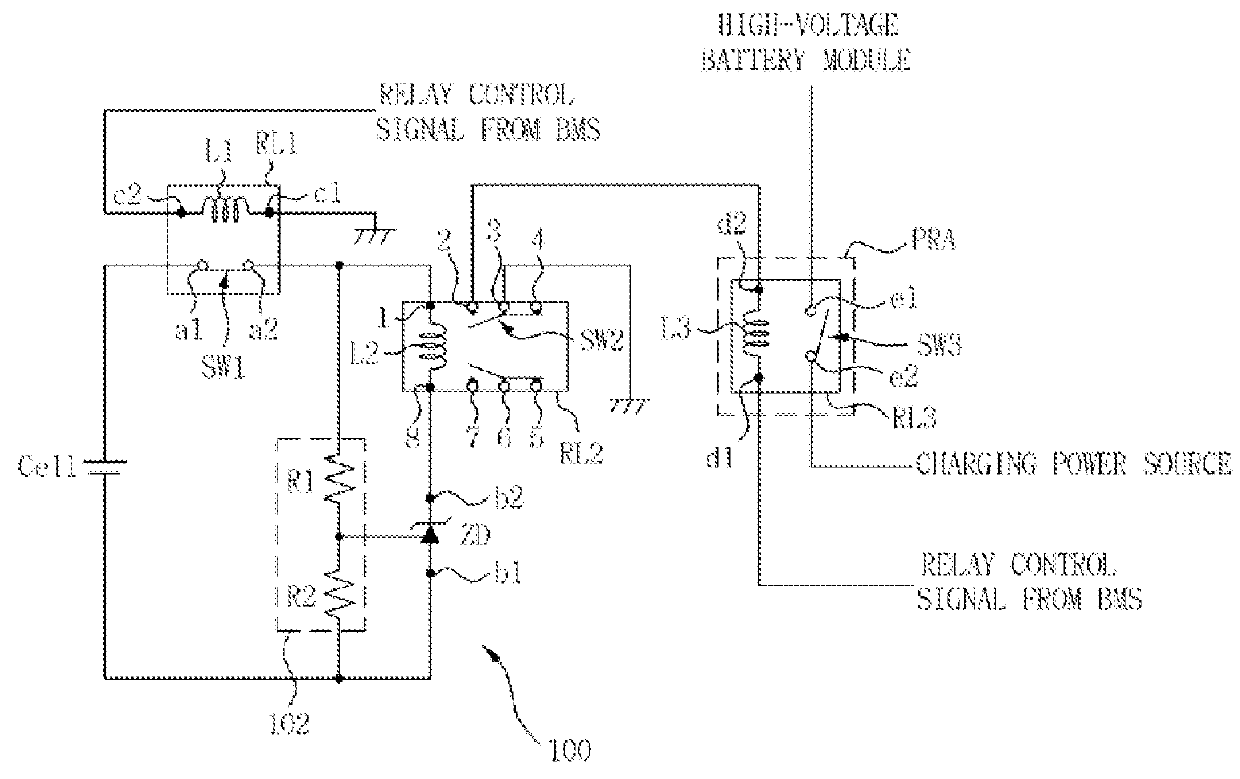

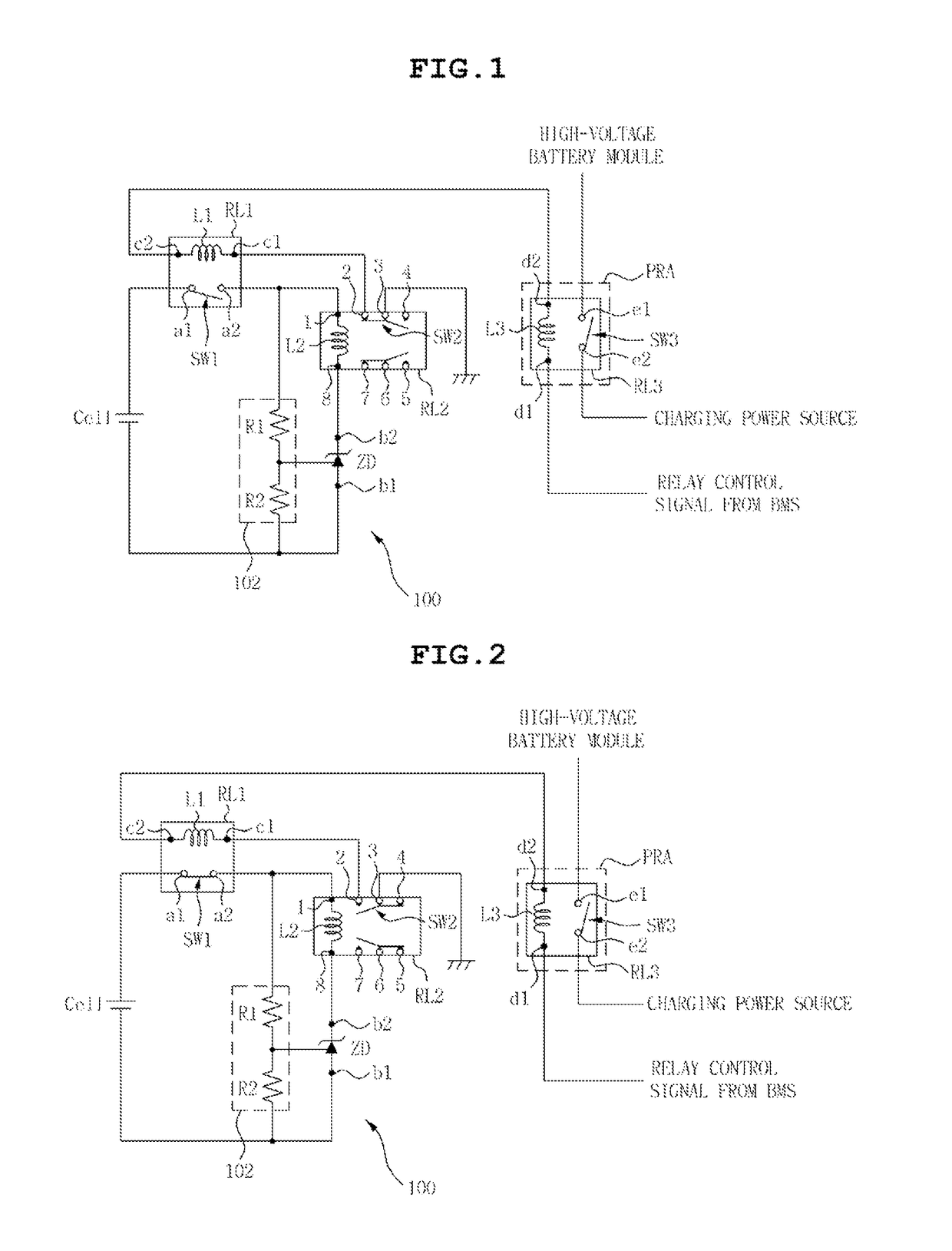

Overcharge protection apparatus with minimized power consumption

ActiveUS20160056646A1Minimize power consumptionReduce voltage differenceElectric devicesPower network operation systems integrationPower dissipation minimizationBattery cell

Disclosed herein is an overcharge protection apparatus with minimized power consumption. An overcharge protection apparatus with minimized power consumption according to an embodiment includes a switching unit for controlling supply of voltage detected in a battery cell depending on an ignition-on or off state of a vehicle, and an overcharge prevention circuit for when the battery cell is overcharged based on the voltage of the battery cell output from the switching unit, turning off a main relay, thus interrupting supply of power to a battery module, so that the voltage of the battery cell is detected only in an ignition-on state of a vehicle and power consumption is Minimized, thus preventing the lifespan of a battery from being shortened by reducing a voltage difference between cells.

Owner:SK ON CO LTD

Battery module and battery system comprising same

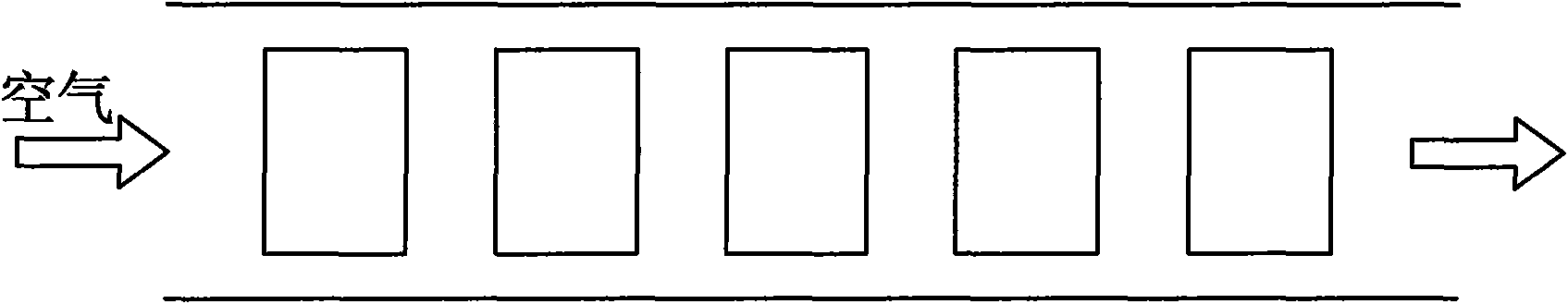

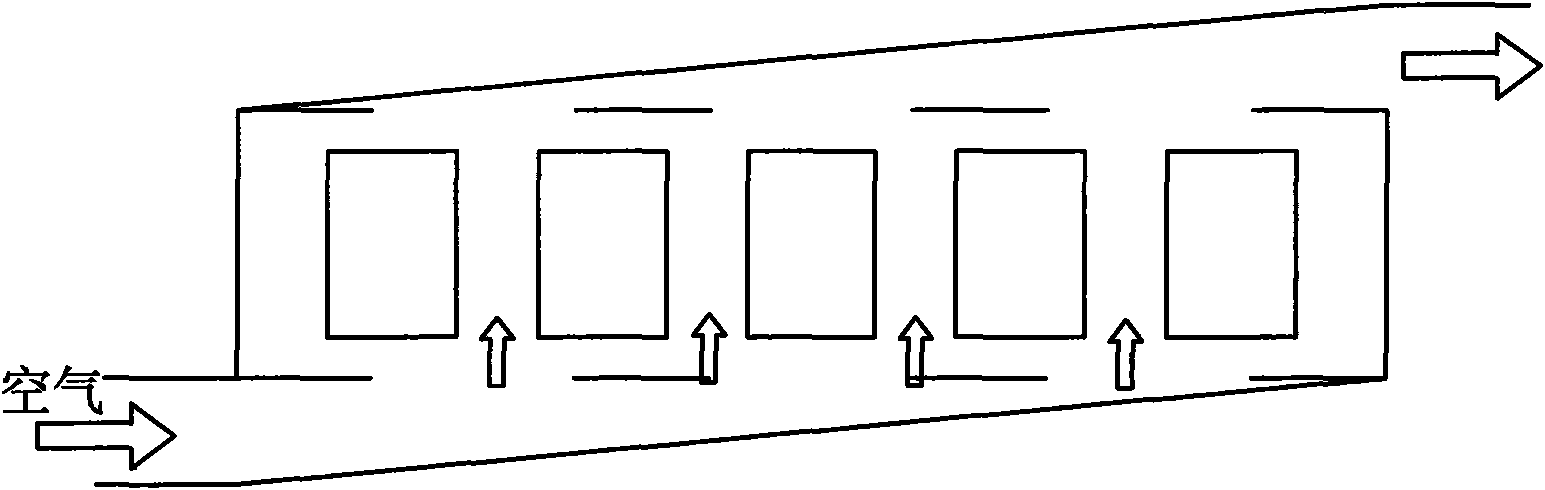

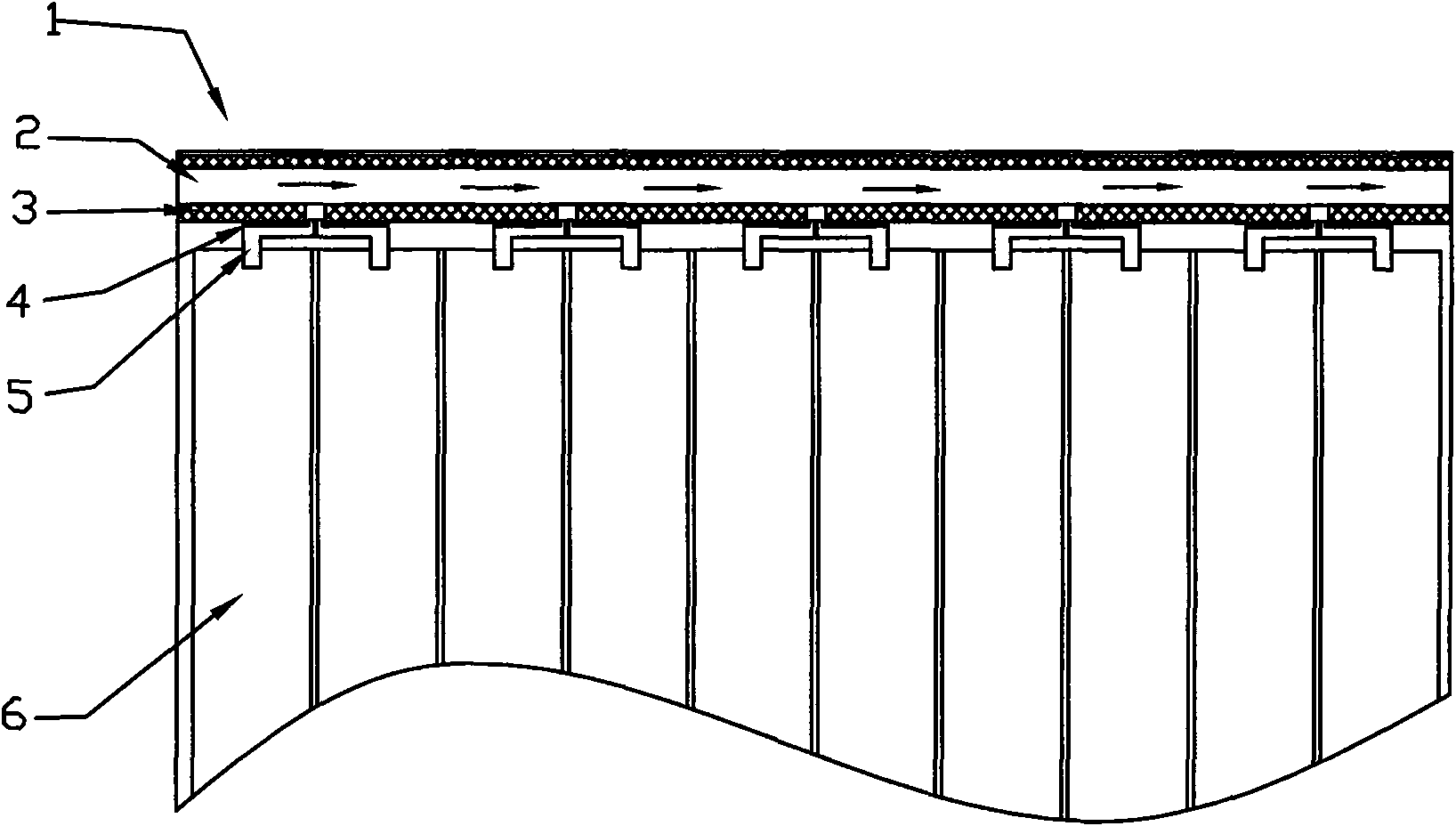

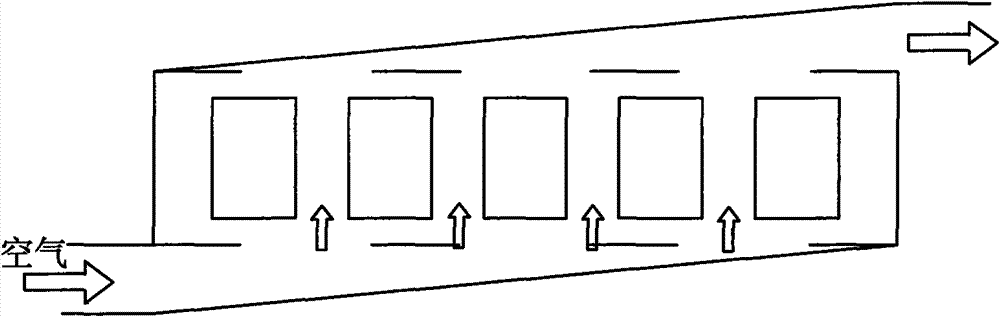

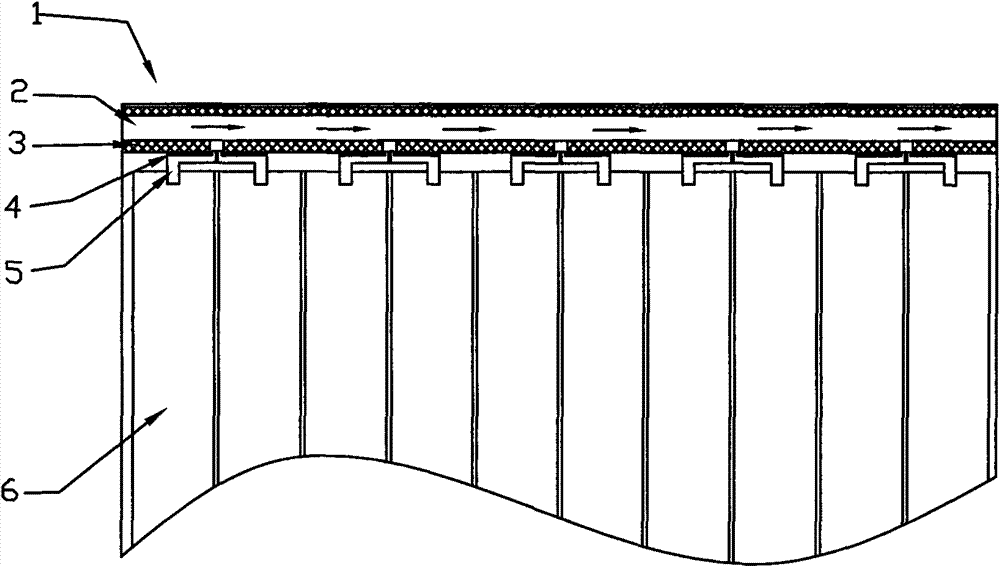

ActiveCN101894964AAvoid lifespanImprove thermal efficiencySecondary cellsHeat managementThermal management system

The invention discloses a battery module and a battery system adopting the battery module, an electrode terminal is arranged on the end surface of a monomer battery, and a plurality of the monomer batteries are connected in series and / or in parallel through the electrode terminals, wherein the battery module further comprises a metal air duct, the metal air duct is in insulation, heat conduction and connection with the electrode terminals, and the metal air duct is used for reducing or increasing the temperature of the monomer batteries. A heat management structure adopted by the battery module and a heat management system of the battery system can effectively regulate the temperature in the battery module, avoid the inconsistencies in battery performances, and further avoid reducing the service life of the batteries or causing safety accidents.

Owner:BYD CO LTD

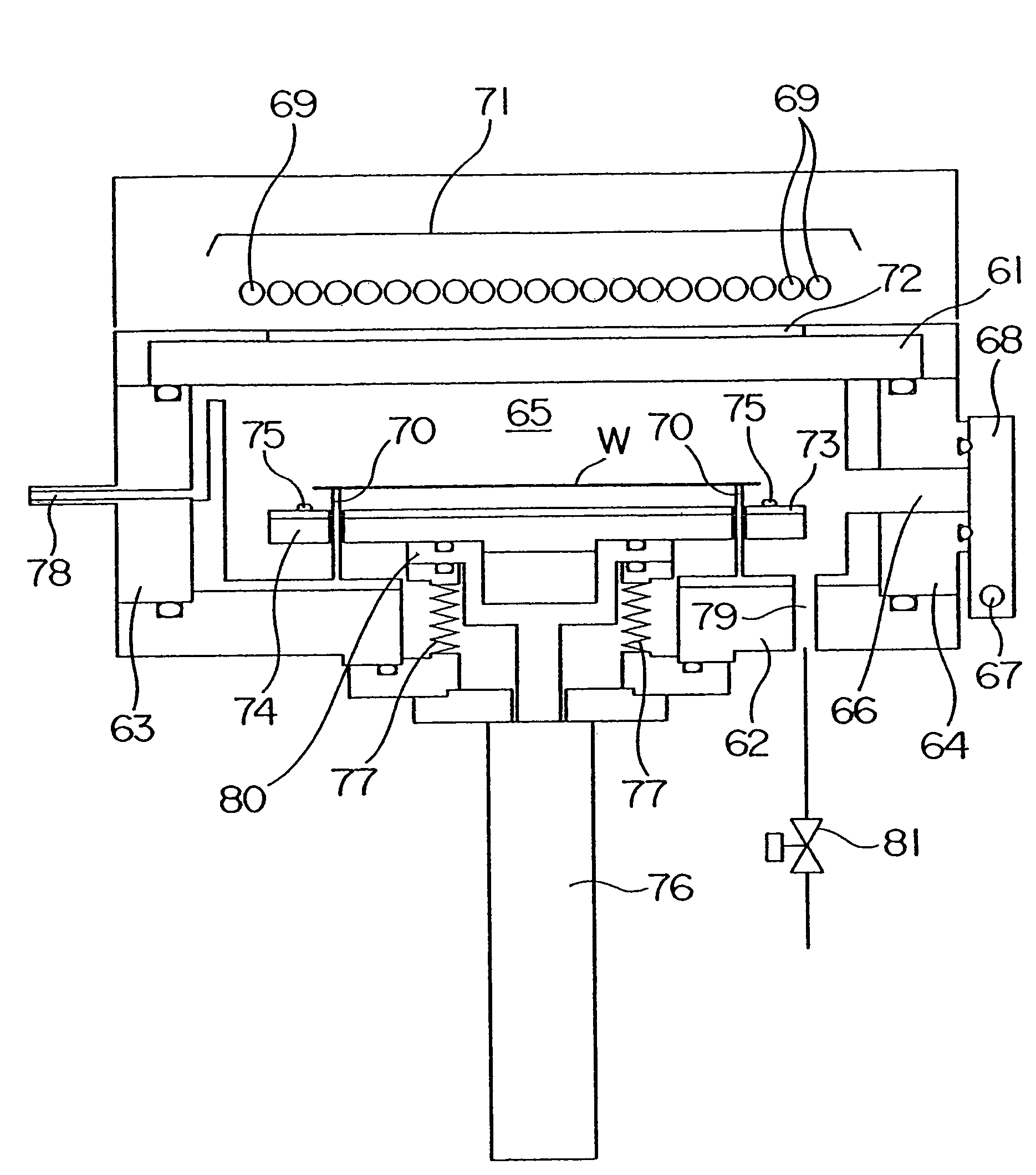

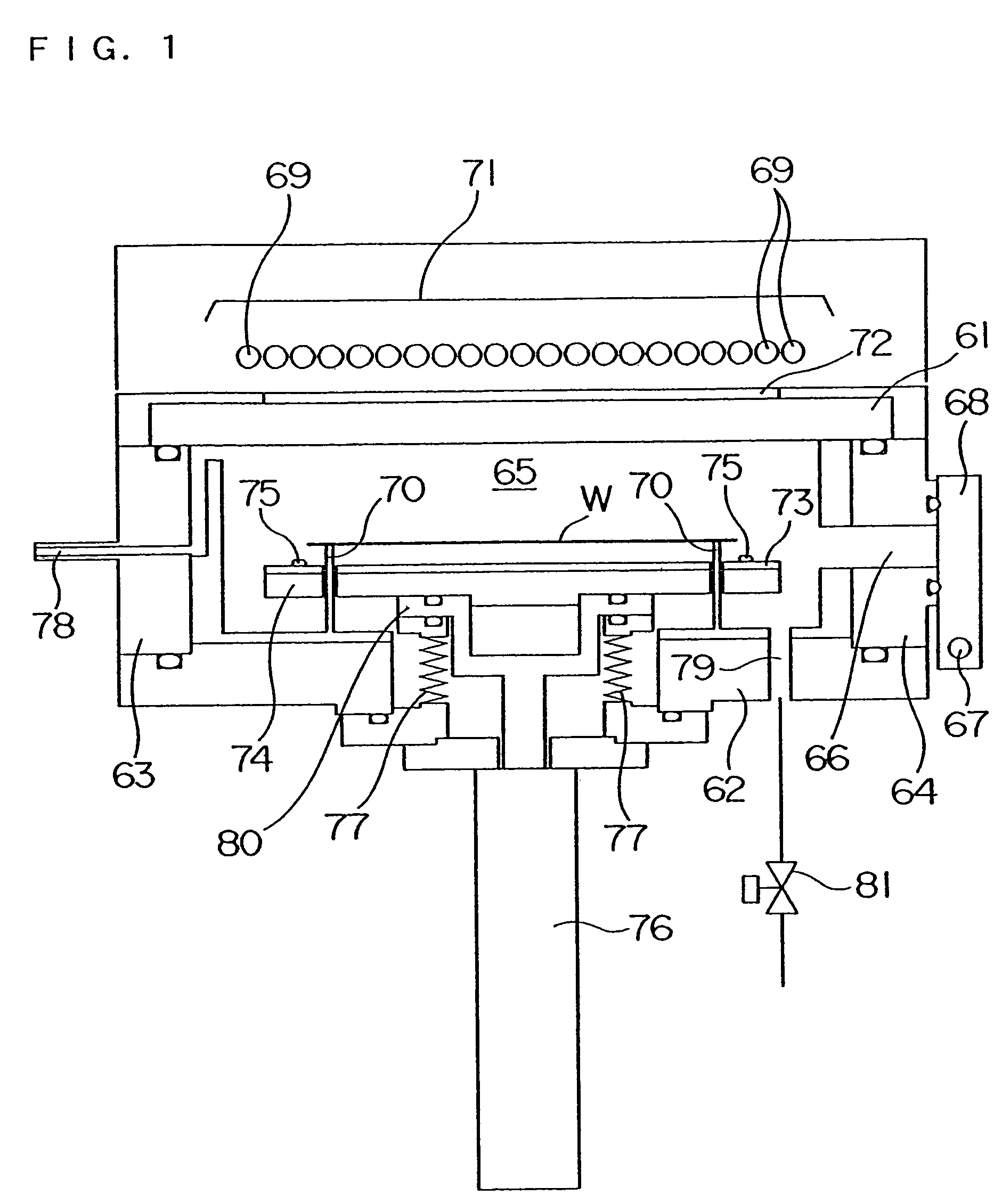

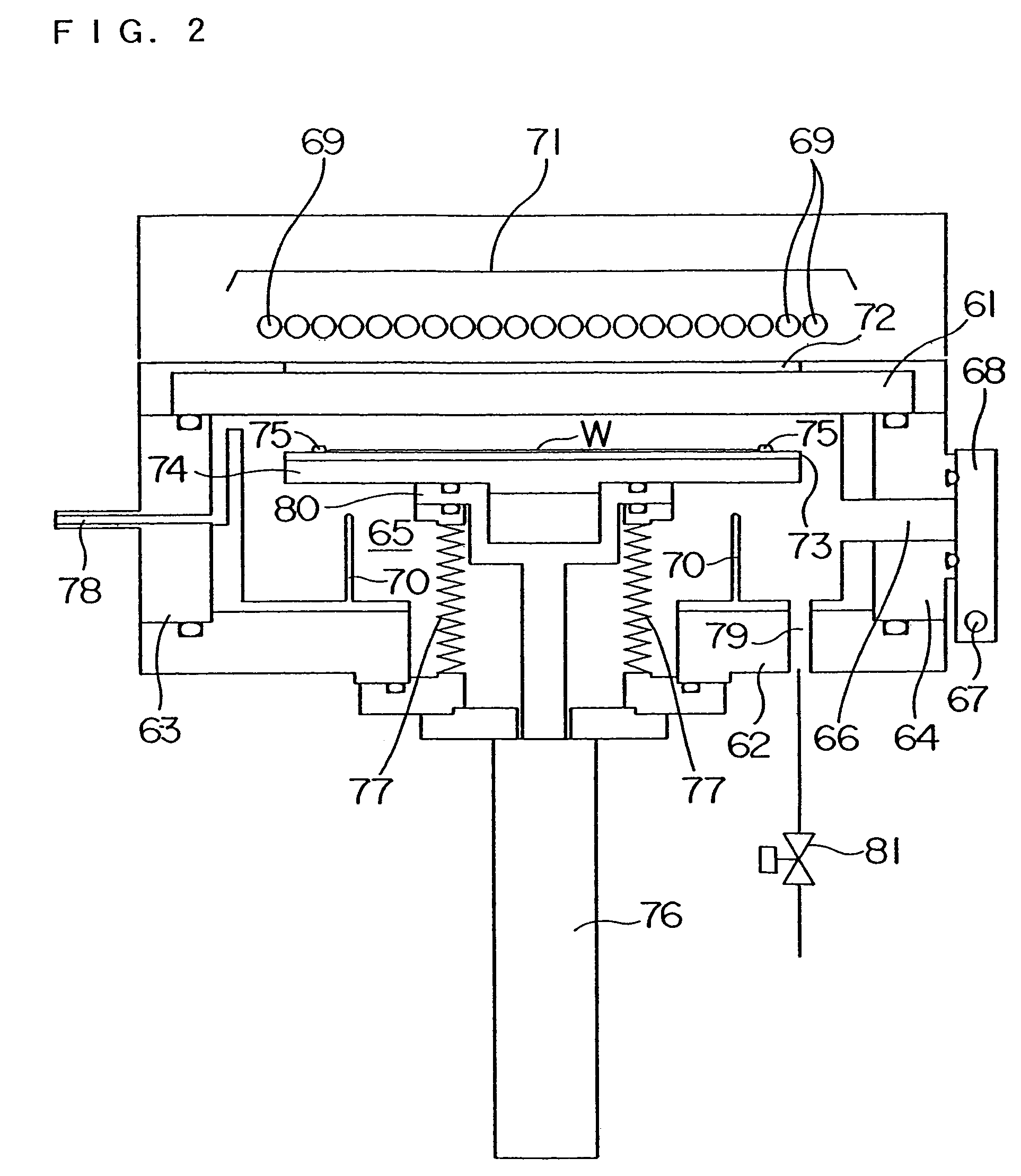

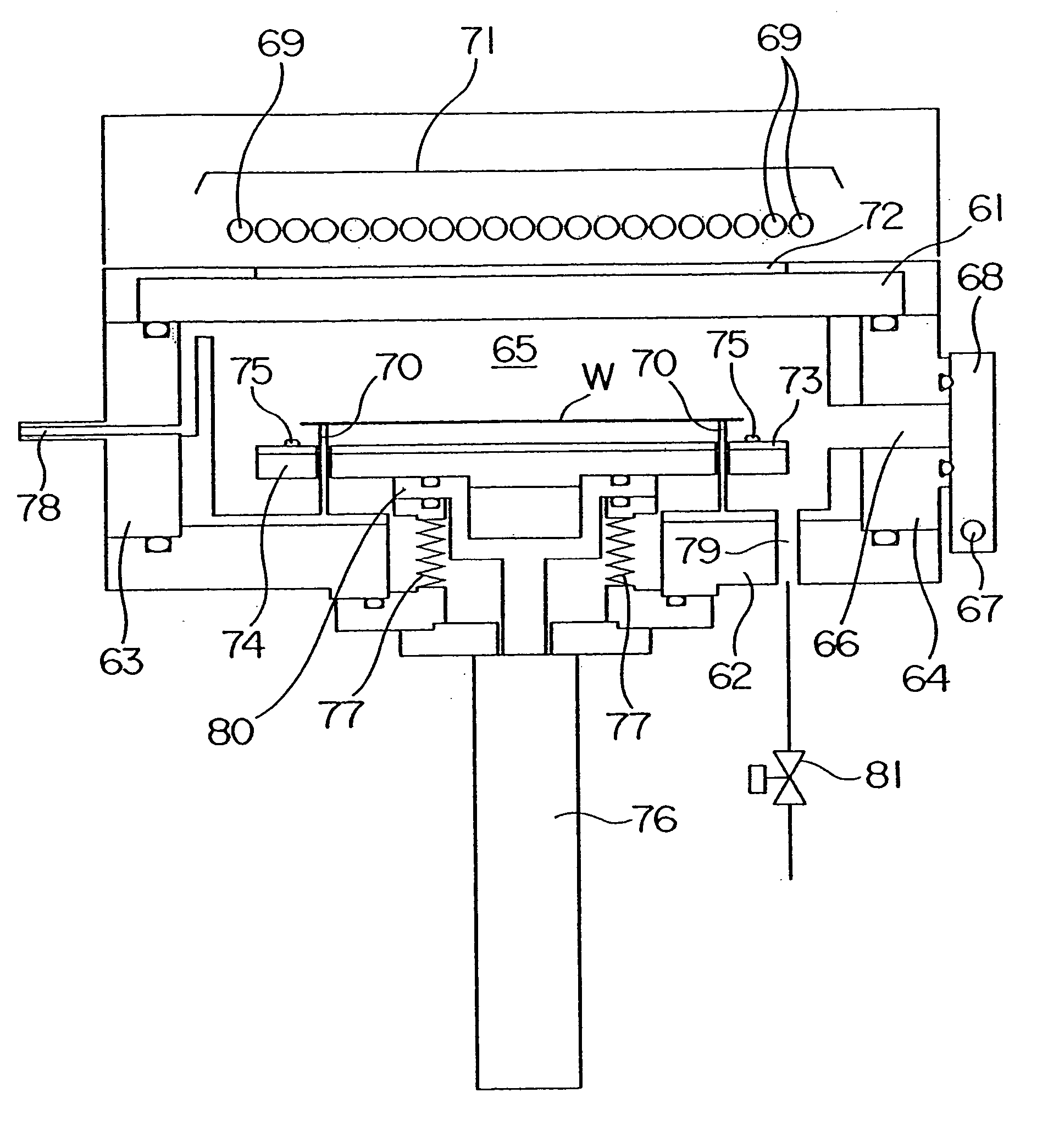

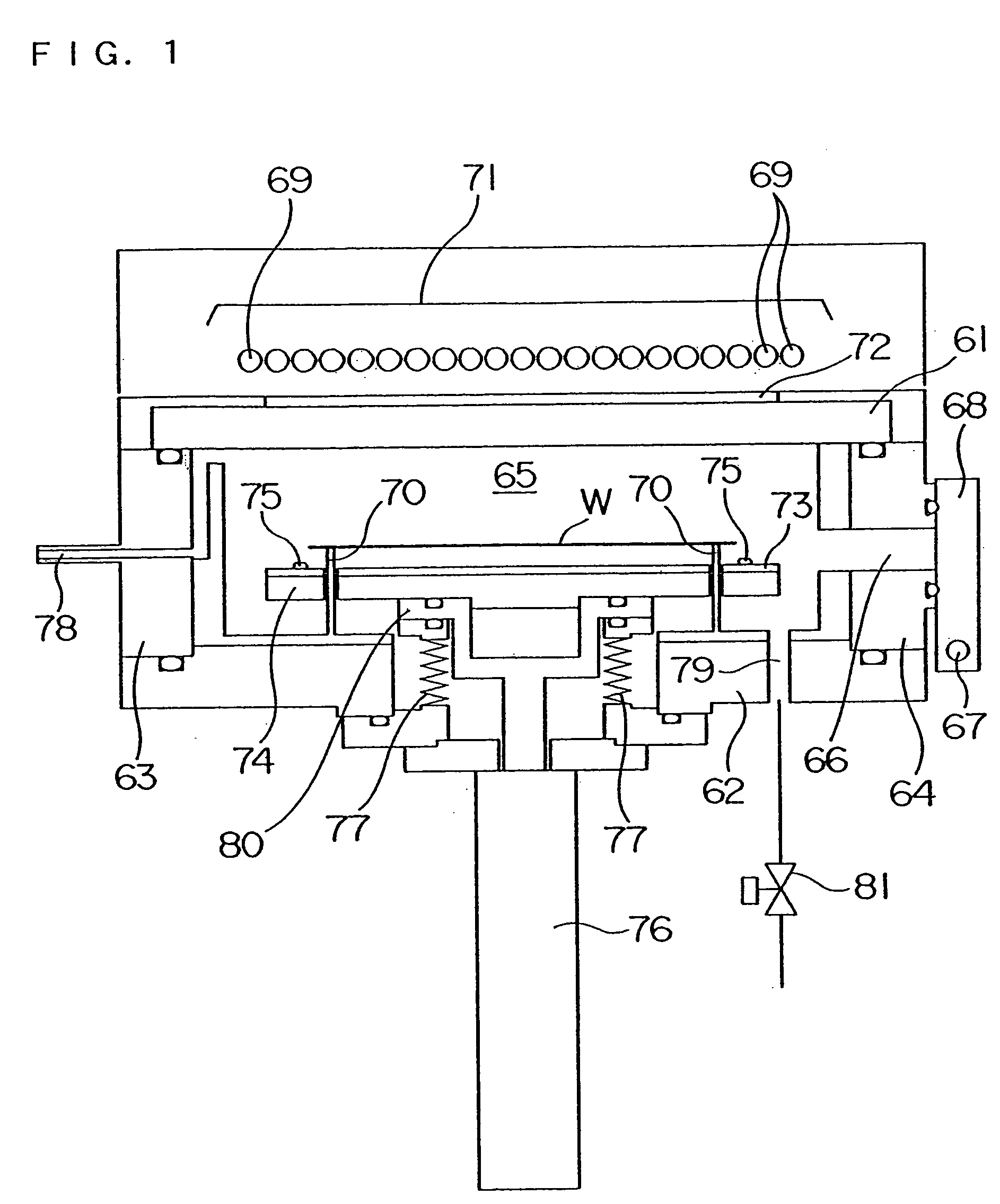

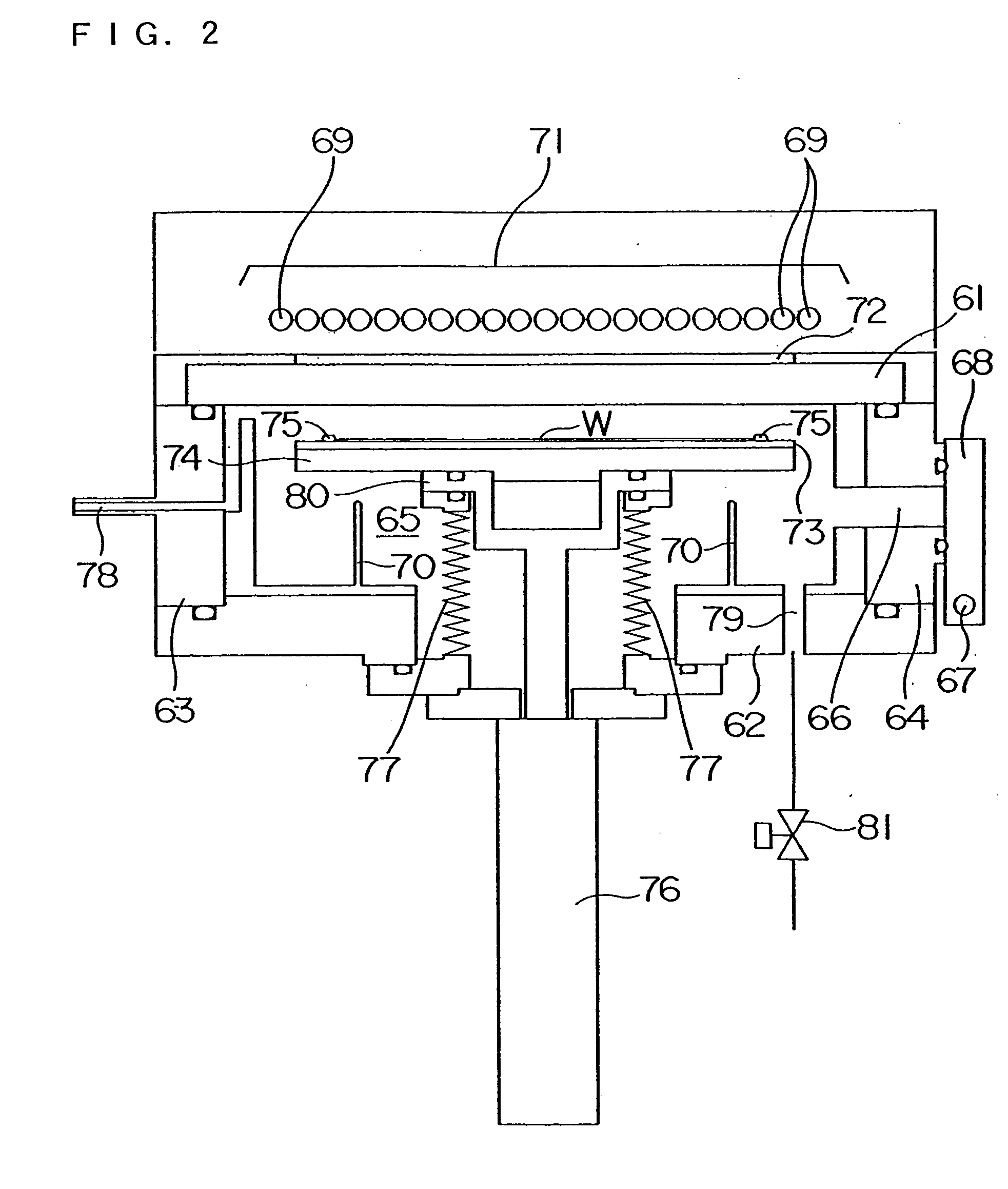

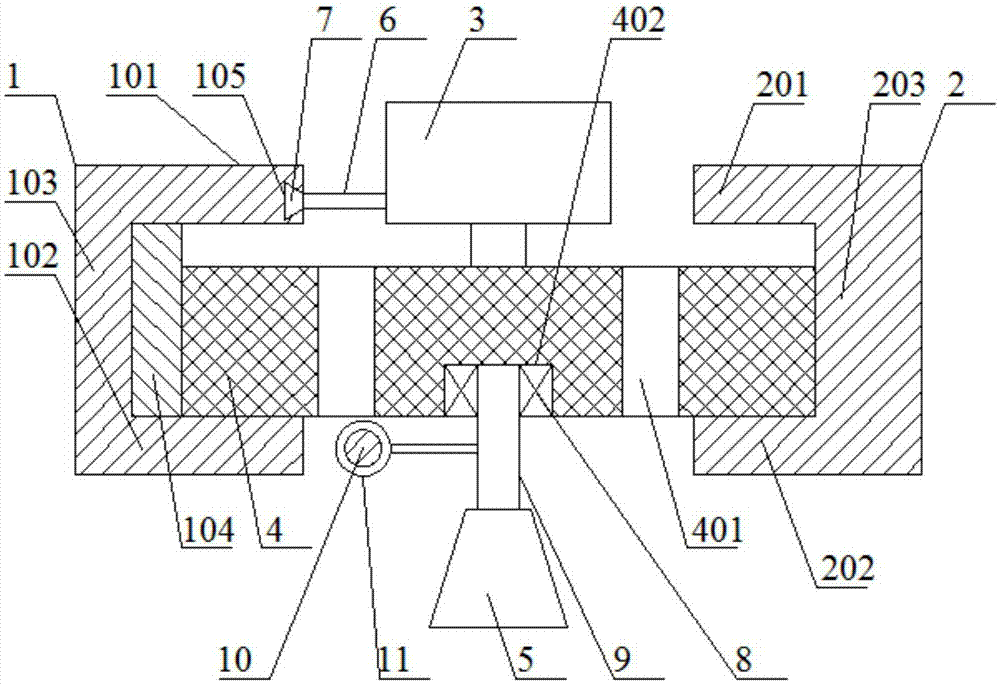

Heat treating apparatus and method

InactiveUS7327947B2Solution to short lifeAvoid lifespanDomestic stoves or rangesDrying solid materials with heatHeat treatedMaterials science

A heat treating apparatus for heat treating a substrate by irradiating the substrate with light includes a heat treating chamber for receiving the substrate, a heating plate for preheating the substrate through a thermal diffuser plate, xenon flashlamps for heating the substrate preheated by the heating plate, to a treating temperature by irradiating the substrate with flashes of light, and a decompression mechanism for decompressing the heat treating chamber when the xenon flashlamps heat the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

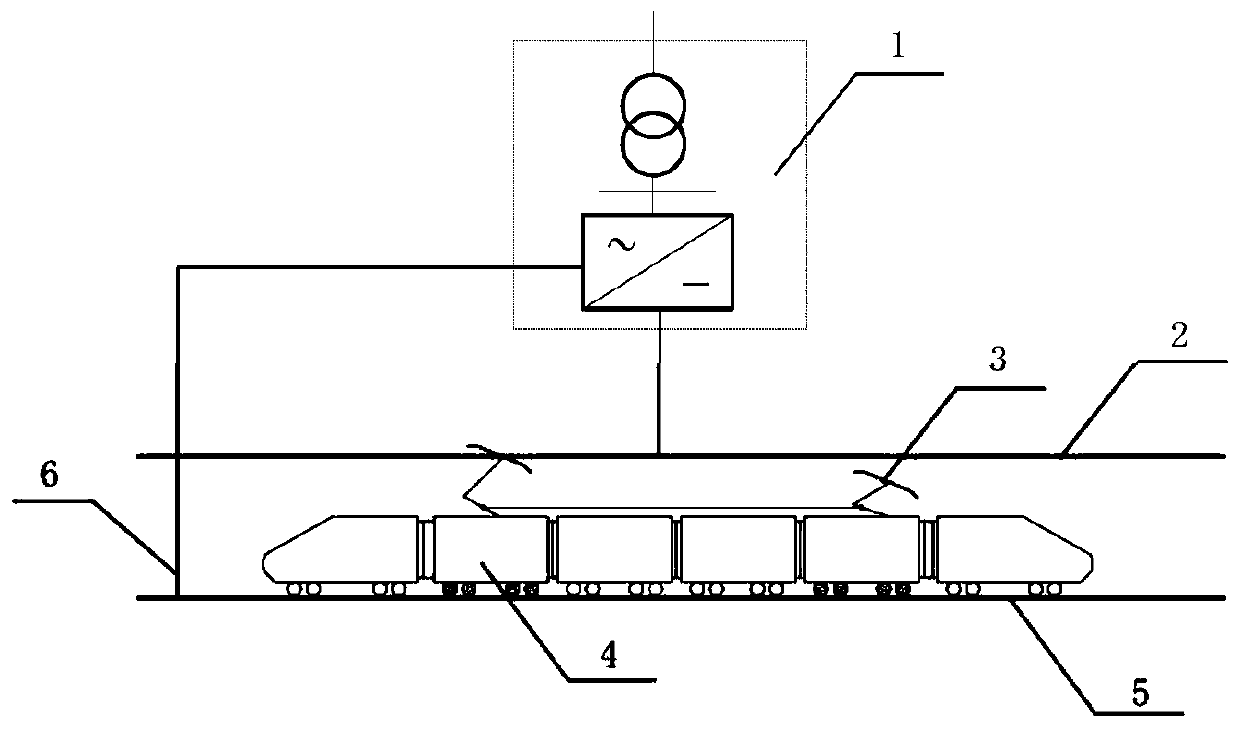

A combined energy storage discharge method for maintaining frequency stability of a power grid

InactiveCN109066729AAvoid lifespanAc network load balancingPower oscillations reduction/preventionCapacitanceFlywheel energy storage

The invention discloses a combined energy storage and discharge method for maintaining the frequency stability of a power network, which solves the problem that the energy storage capacity of a supercapacitor and a flywheel is limited and the capacity is insufficient when charging and discharging for a long time is required. The method comprises selecting a flywheel energy storage device; selecting a storage battery energy storage device; after connecting the flywheel energy storage device and the battery energy storage device in parallel to the power grid, the electric energy storage of the two energy storage devices should be kept at about 50% of their rated capacity. When the unbalanced frequency of power supply and demand decreases, that is, when the power consumption is greater than the power generation, first starting the flywheel energy storage device to discharge; If the frequency of the power grid has been balanced before the power margin exceeds 2-3 seconds, terminating thedischarge of the flywheel energy storage device; If, the grid frequency is not balanced before the flywheel energy storage device of the remaining power capacity of 2-3 seconds, , then startting the battery energy storage device discharge to ensure the continuity of the discharge for the grid frequency modulation.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER

Heat treating apparatus

InactiveUS20050274709A1Without reducing lifeSolution to short lifeDomestic stoves or rangesDrying solid materials with heatFlash lightMaterials science

A heat treating apparatus for heat treating a substrate by irradiating the substrate with light includes a heat treating chamber for receiving the substrate, a heating plate for preheating the substrate through a thermal diffuser plate, xenon flashlamps for heating the substrate preheated by the heating plate, to a treating temperature by irradiating the substrate with flashes of light, and a decompression mechanism for decompressing the heat treating chamber when the xenon flashlamps heat the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

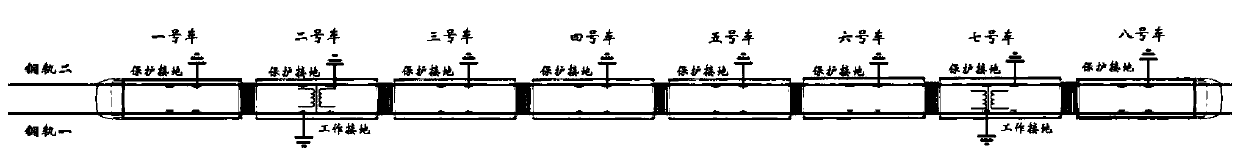

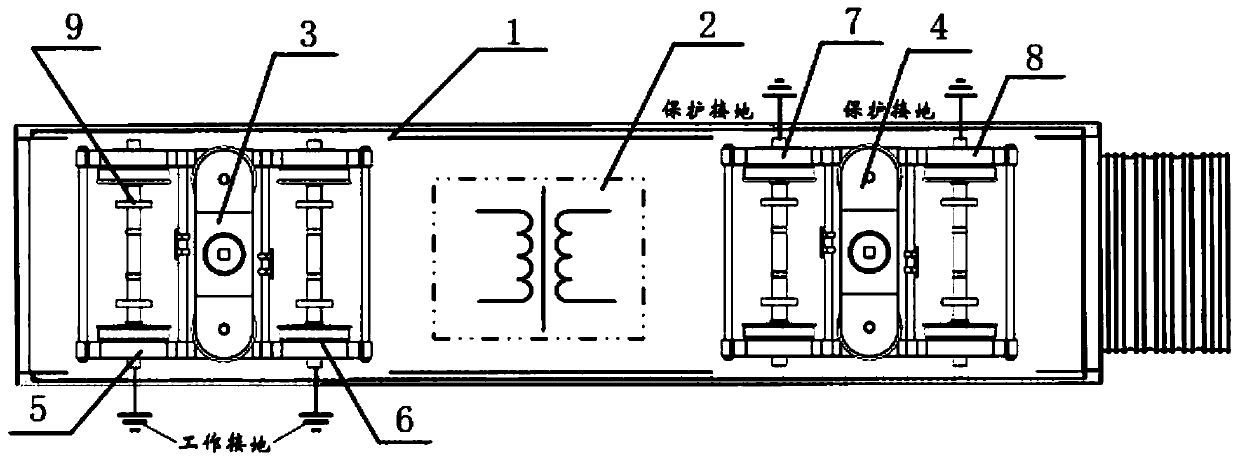

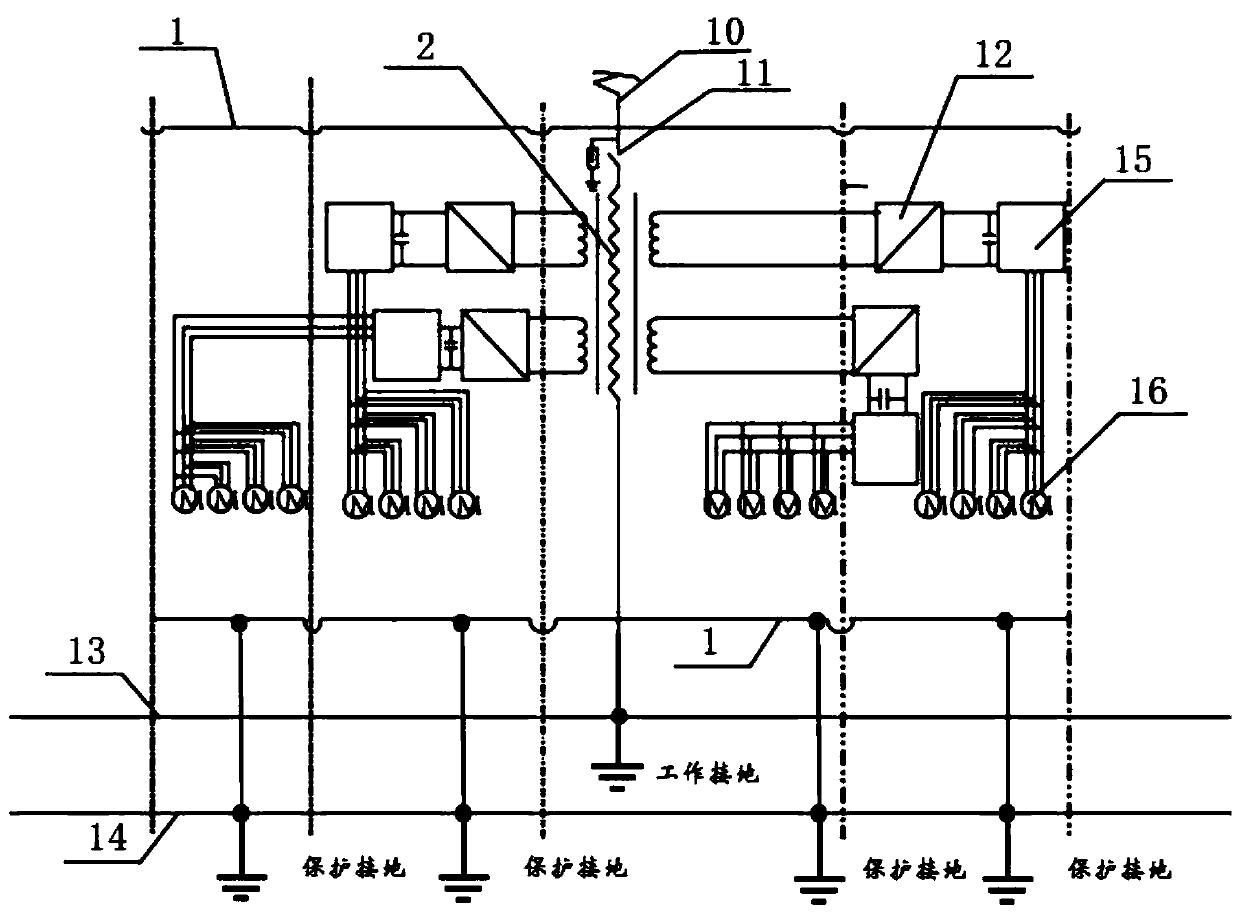

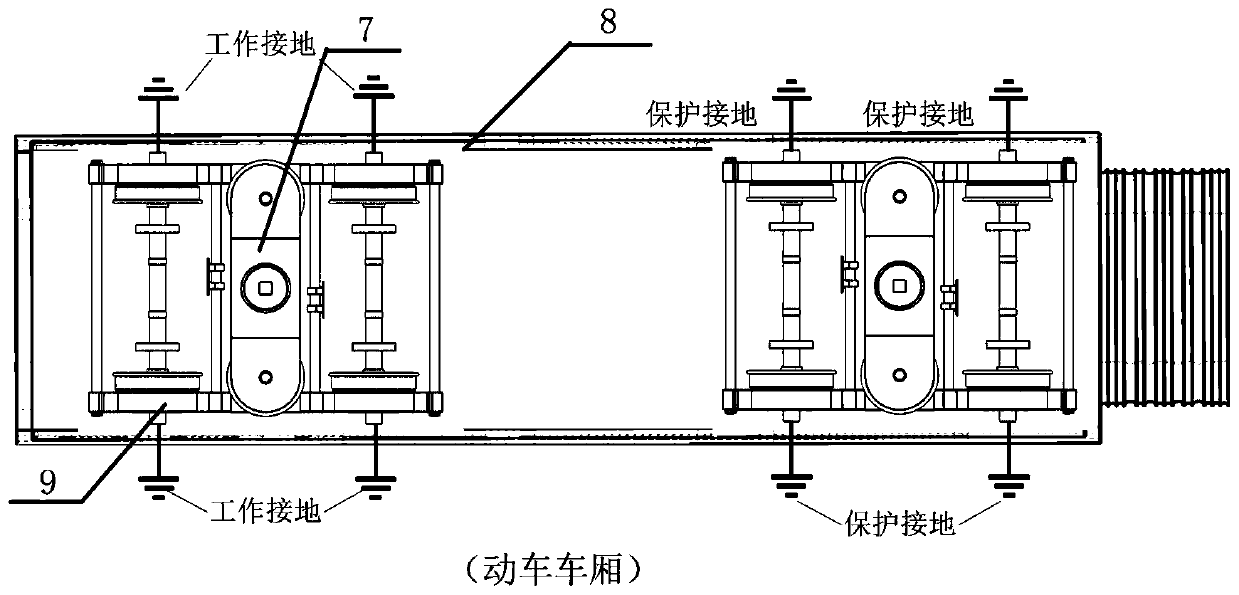

Working grounding and safe grounding independent distribution method suitable for high-speed train

The invention discloses a working grounding and safe grounding independent distribution method suitable for a high-speed train. The method comprises the specific steps that a working grounding systemand a safe grounding system are independently distributed on two steel rail sides; a compartment of the working grounding system is connected with the high-voltage alternating current through a pantograph type current collector from the contact network, and the high-voltage alternating current is transmitted to the primary side of a transformer through a vacuum circuit breaker, then is in slidingcontact with wheels through a grounding carbon brush, then is in rolling contact with a first steel rail and finally reaches a return line of a substation through the first steel rail for form return;and the compartment of the safe grounding system is directly in sliding contact with wheels by the grounding carbon brush and then is in rolling contact with a second steel rail to discharge the overvoltage. By the adoption of the working grounding and safe grounding independent distribution method, the circulation of a vehicle body can be effectively reduced, the problems that vehicle-mounted weak current equipment is interfered by the circulation of the vehicle body, abnormal heating of the equipment is generated and abnormal wear of the grounding carbon brush is caused are avoided; and thedamage caused by the impact voltage generated by the overvoltage is reduced, and the grounding stability of a train is improved.

Owner:SOUTHWEST JIAOTONG UNIV

Overcharge protection apparatus with minimized power consumption

ActiveUS9768627B2Minimize power consumptionAvoid lifespanElectric devicesPower network operation systems integrationElectrical batteryComputer module

Owner:SK ON CO LTD

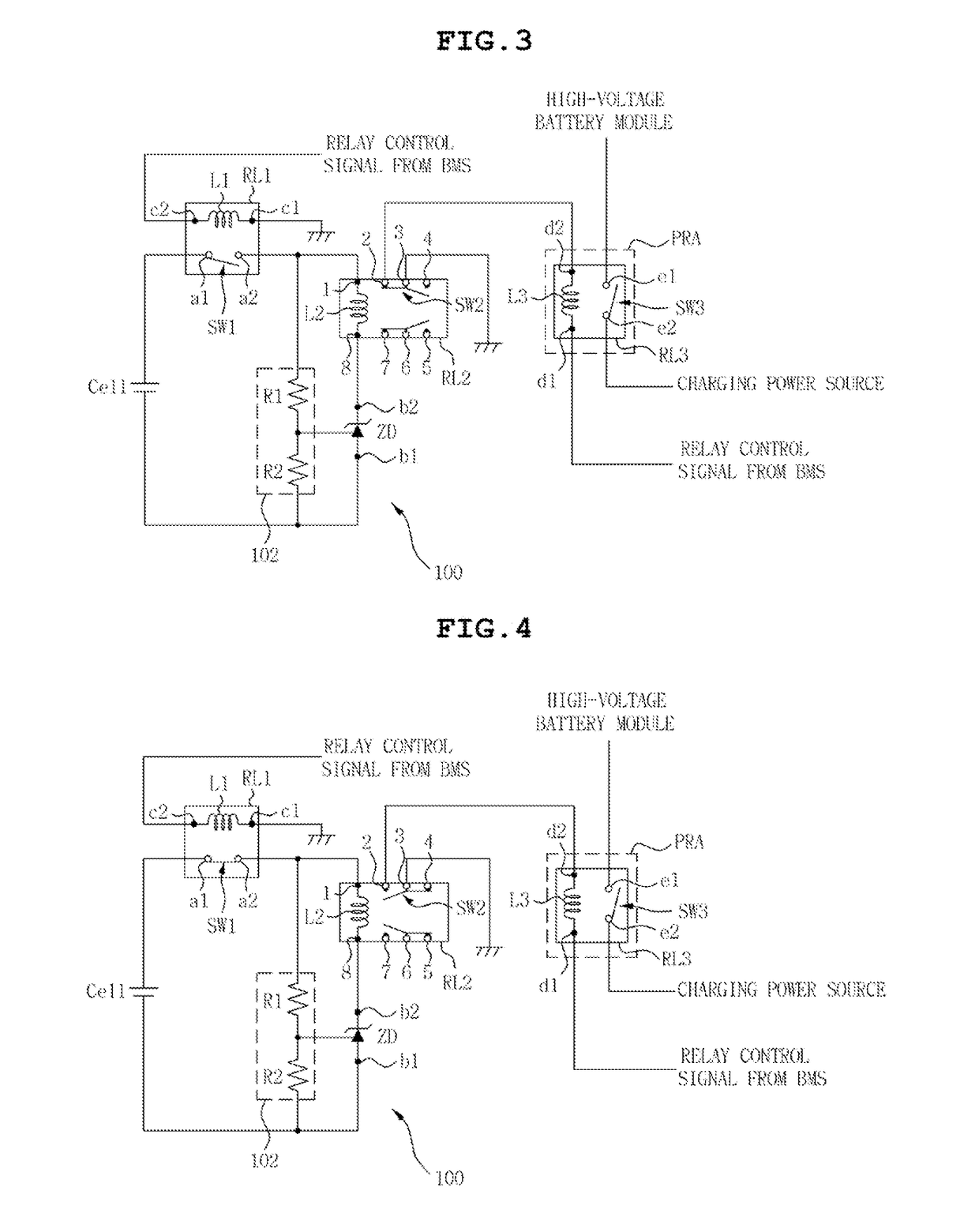

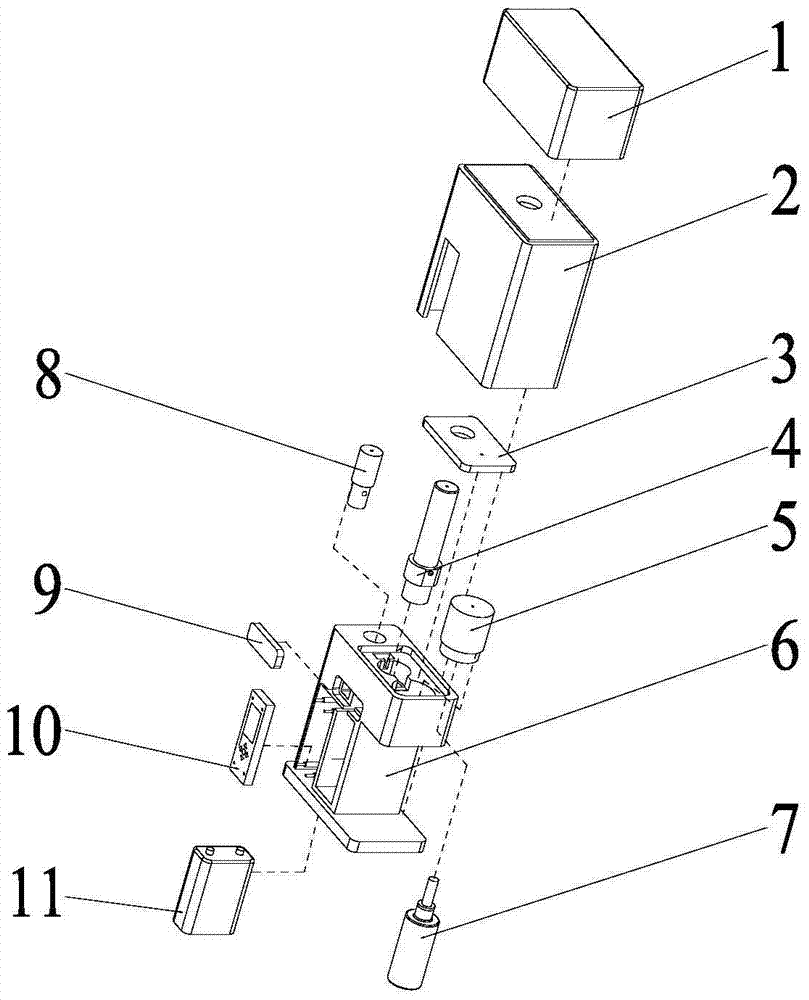

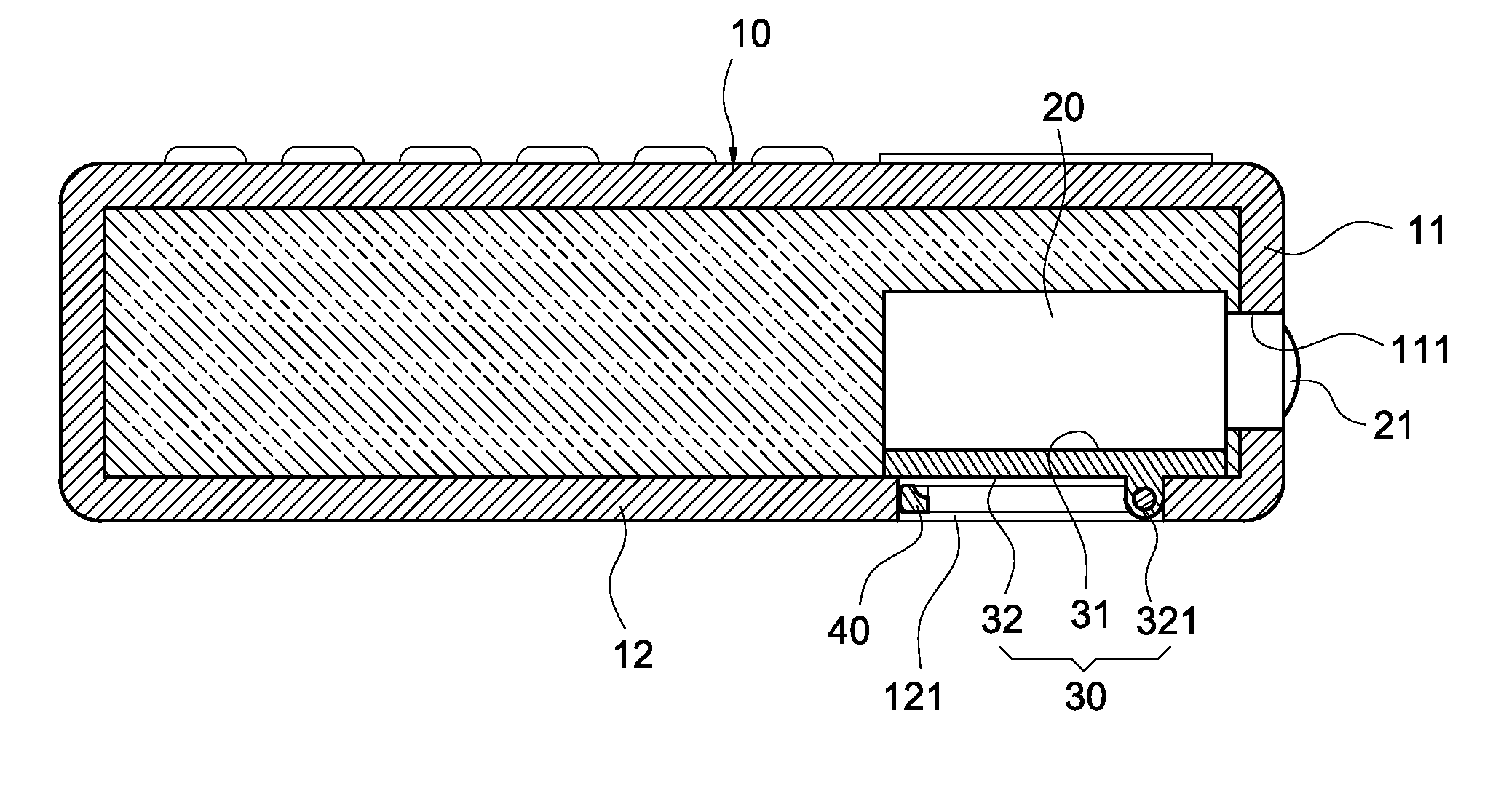

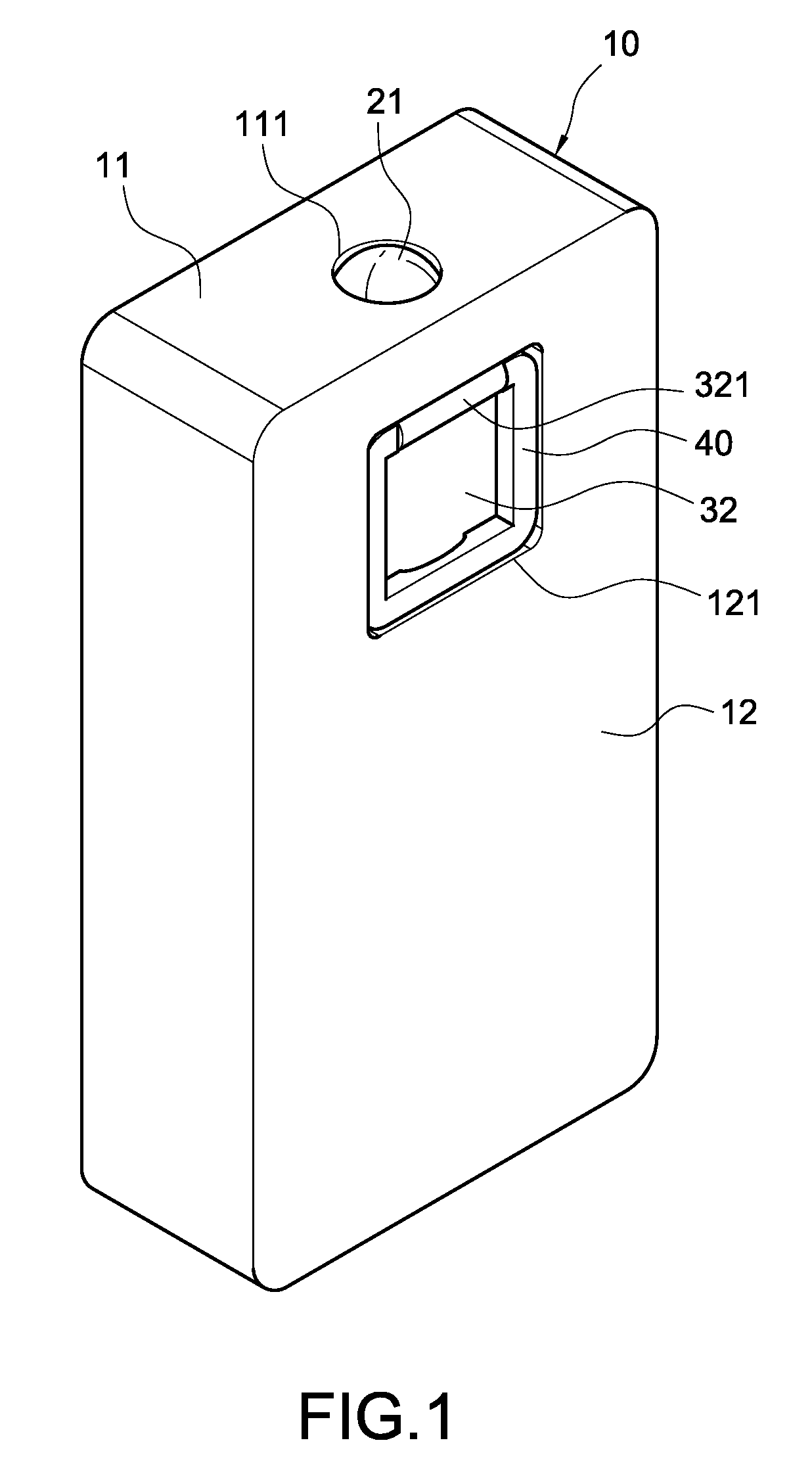

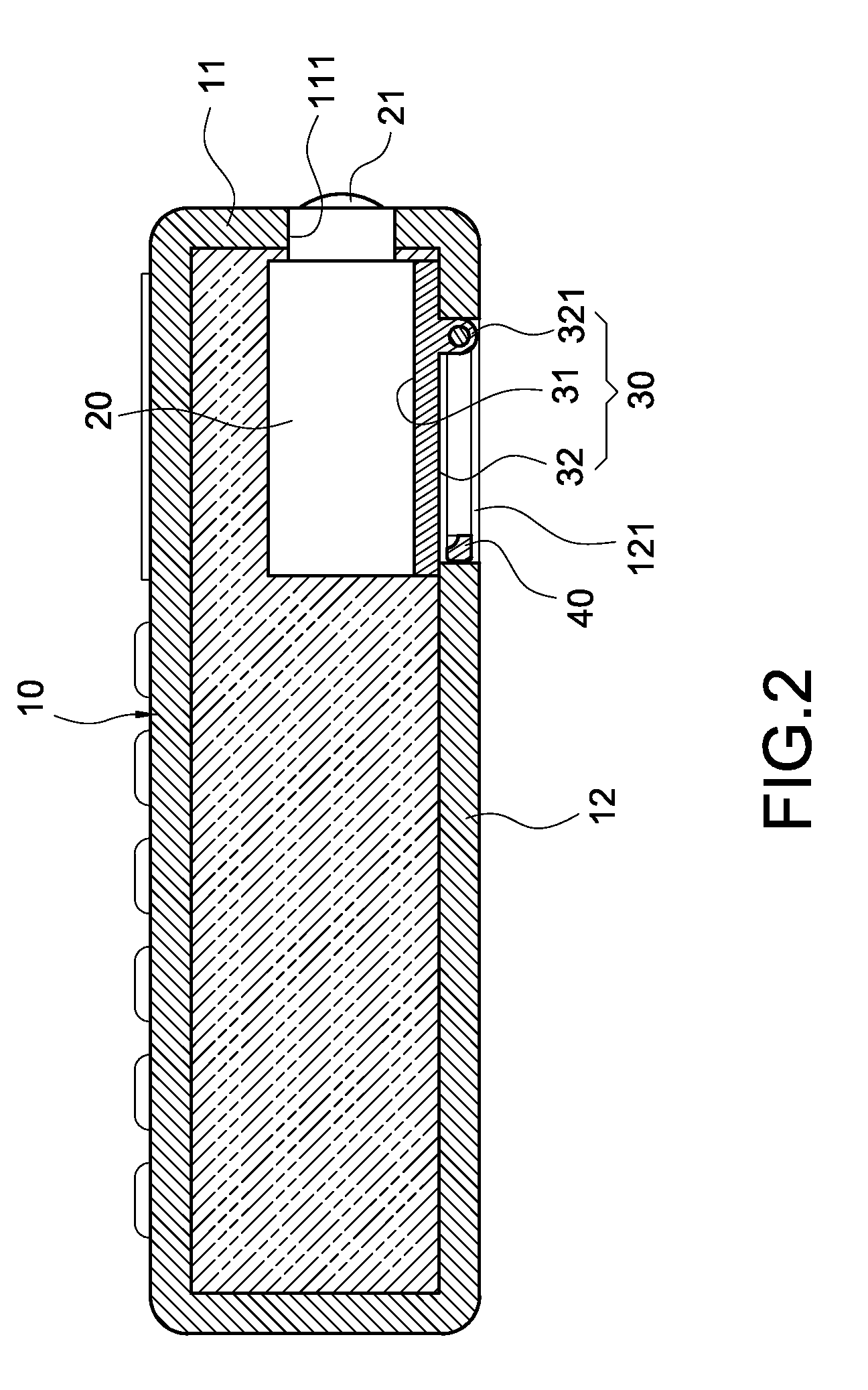

Portable Intelligent Ultrasonic Nebulizer

InactiveCN105268590BEasy to replaceStructure miniaturizationLiquid spraying apparatusTransformerEngineering

Owner:SHANGHAI INST OF TECH

Portable electronic device with micro-projecting module

InactiveUS8092027B2Heat dissipationAvoid brightnessProjectorsMicroscopesHeat conductingComputer module

Owner:CHUANG YI FANG

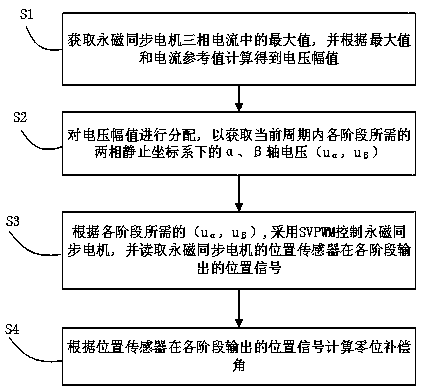

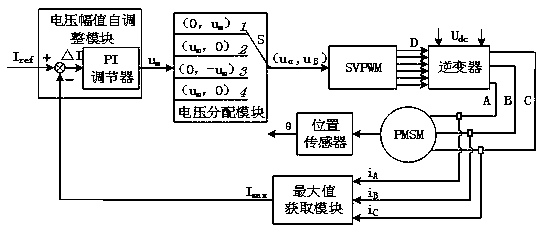

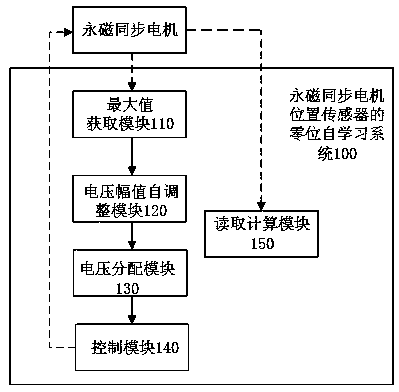

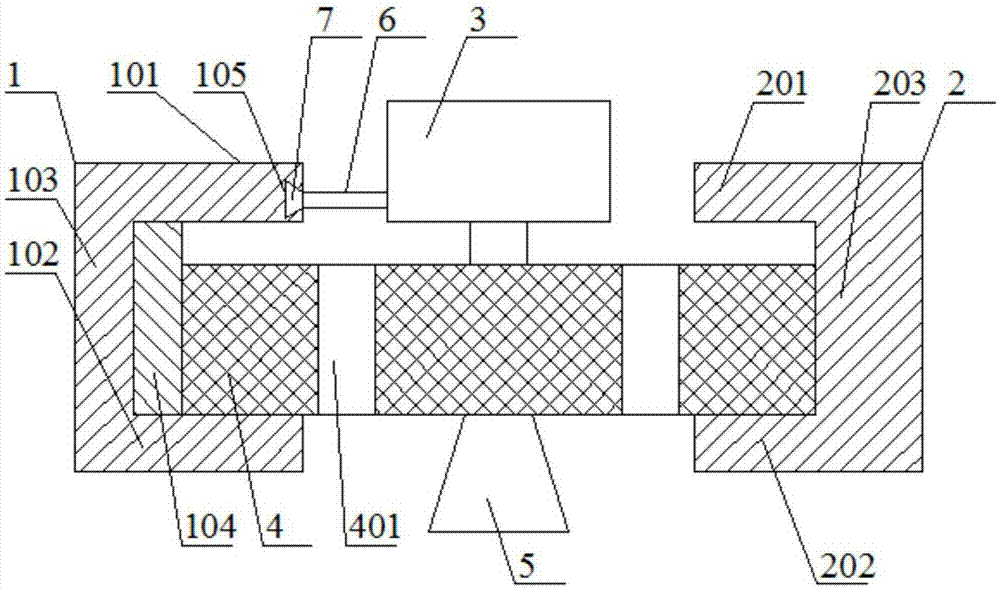

Zero position self-learning method and system for position sensor of permanent magnet synchronous motor

ActiveCN110572103AReduce operational complexityAvoid lifespanElectronic commutation motor controlVector control systemsVoltage amplitudePower flow

The invention provides a zero position self-learning method and system for a position sensor of a permanent magnet synchronous motor. The method comprises the steps of obtaining the maximum value of three-phase current of the permanent magnet synchronous motor, and obtaining a voltage amplitude through calculation according to the maximum value and a current reference value; distributing the voltage amplitude to obtain alpha and beta axis voltages (u<alpha>, u<beta>) required by each stage in the current period under a two-phase static coordinate system; controlling the permanent magnet synchronous motor by adopting SVPWM (space vector pulse width modulation) according to the (u<alpha>, u<beta>) required by each stage, and reading position signals output by a position sensor of the permanent magnet synchronous motor in each stage; and calculating a zero position compensation angle according to the position signals output by the position sensor in each stage. According to the zero position self-learning method, the zero position self-learning process in which the motor current can be controlled in a closed-loop mode and the current amplitude can be adjusted is achieved, the voltageamplitude does not need to be adjusted manually, the operation complexity is reduced, and meanwhile, the problems that the service life of the motor is shortened due to overcurrent and the motor cannot rotate due to too small current can be solved.

Owner:NANJING YUEBOO POWER SYST CO LTD

Track light

InactiveCN106855197AAvoid lifespanLow costLighting applicationsMechanical apparatusElectricityEngineering

The invention discloses a track light. The track light comprises a driving track, a supporting track, a motor, a gear and a light body. The driving track further comprises a horizontal rack fixed to the side face of a vertical section A, and the horizontal rack is located between an upper horizontal section A and a lower horizontal section A. The driving track and the supporting track are oppositely arranged left and right. The gear is horizontally distributed and located between the driving track and the supporting track, the gear is supported by a lower horizontal section A and a lower horizontal section B together, and the gear is meshed with the horizontal rack; the motor is disposed above the gear, an output shaft of the motor is connected with the center of the gear, the motor is fixed on the upper horizontal section A, and the motor can slide in the horizontal direction along the upper horizontal section A; the light body is disposed on the lower surface of the gear. Switching of illumination areas can be achieved only with one light, the cost is low, the electricity consumption is low, and the situation that the service life of the light is shortened due to frequent switching-on and switching-off of the light is avoided.

Owner:潼南县铭辉灯具制造厂

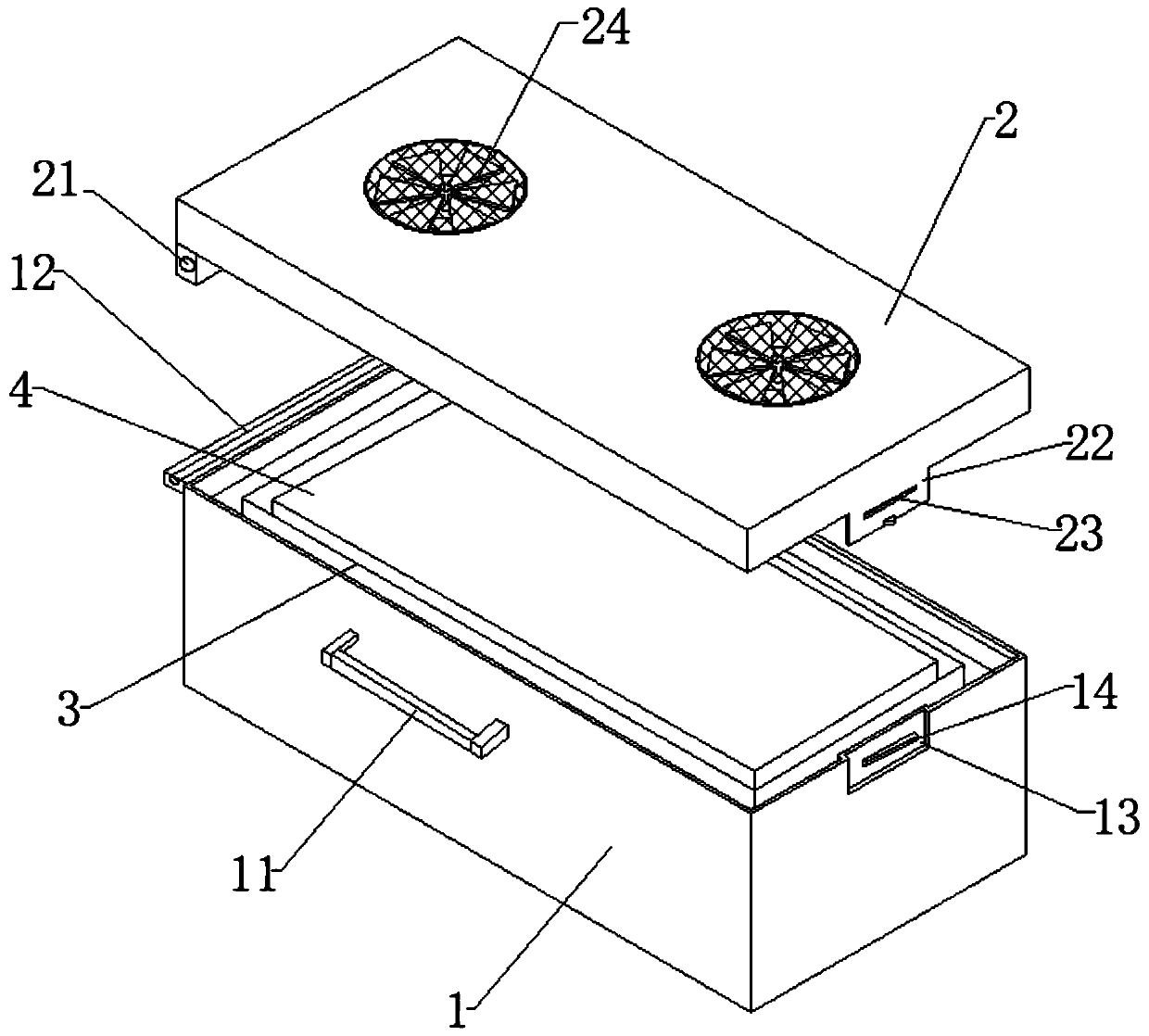

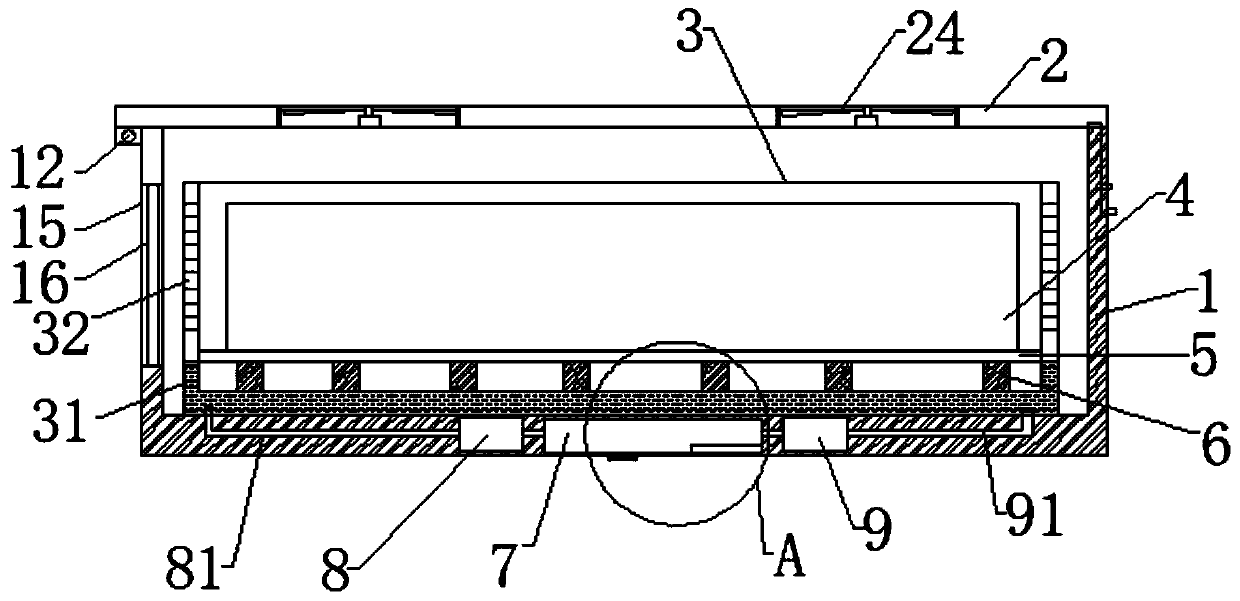

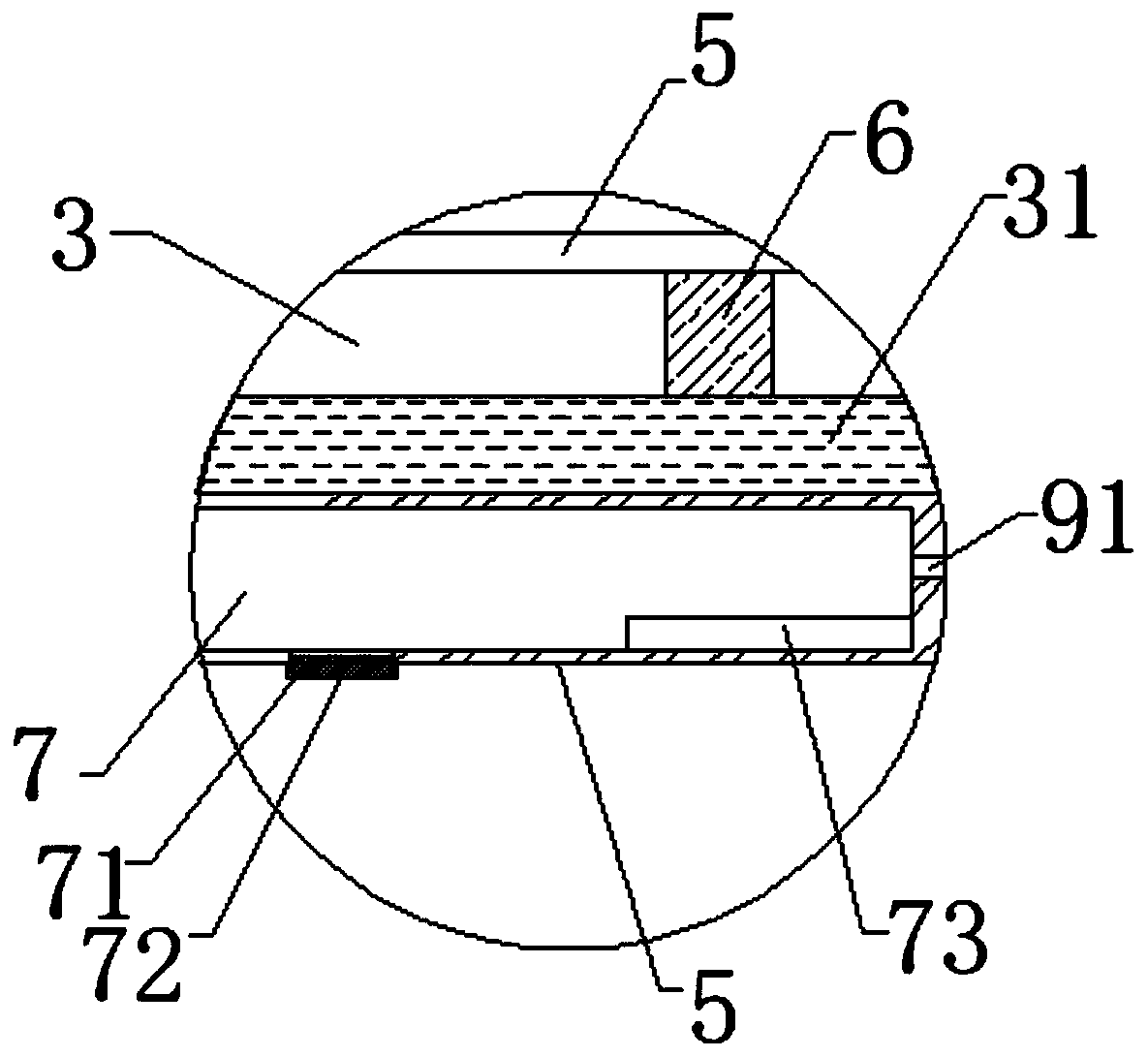

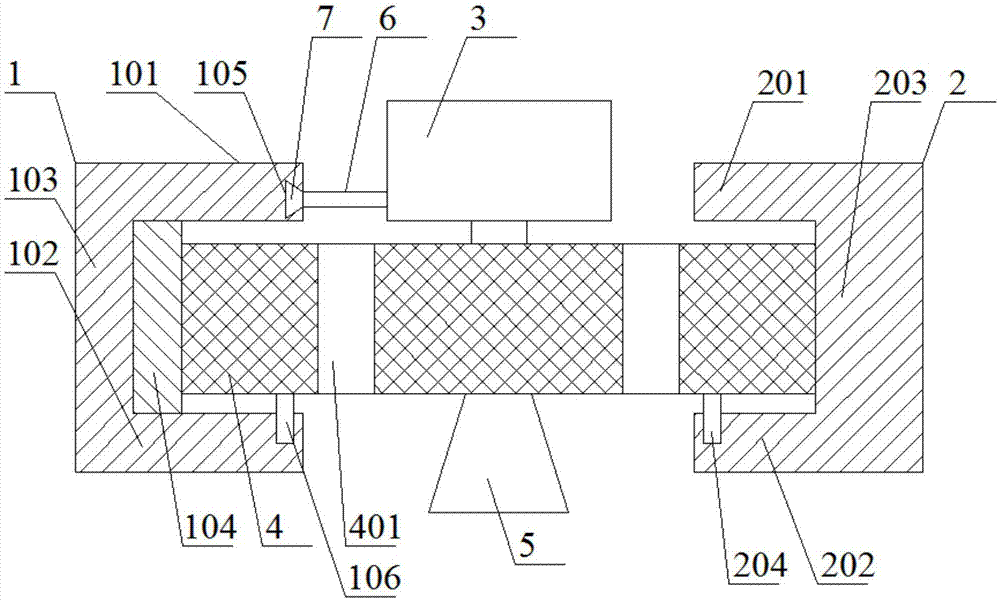

Electric automobile battery pack with good heat dissipation performance

PendingCN111370603AConvenient inspection, maintenance and replacementImprove temperature resistanceBattery isolationSecondary cellsElectrical batteryAutomotive battery

The invention belongs to the technical field of automobile batteries. The invention discloses an electric automobile battery pack with good heat dissipation performance. The battery pack comprises anouter box, a box cover, a heat dissipation inner box and a battery pack, a hinge shaft is mounted at one end of the outer box; the box cover is hinged with the outer box through the hinge shaft; the other end of the box cover is clamped with the outer box; a heat dissipation inner box is mounted in the outer box, a plurality of buffer spring columns are mounted at the bottom in the heat dissipation inner box, a mounting base is fixedly connected to the tops of the buffer spring columns, a battery pack is mounted on the mounting base, and a refrigeration water cavity, a first circulating pump and a second circulating pump are mounted in a bottom plate of the outer box. According to the invention, the outer box and the box cover are clamped and connected in a running fit manner; the mountingbase and the buffer spring columns are arranged at the inner bottom of the heat dissipation inner box, damage caused by shaking is avoided, a refrigeration piece in an inner cavity of a refrigerationwater cavity cools circulating water, the circulating water is conveyed to the inner cavity of the heat dissipation water cavity through a first circulating pump and a second circulating pump, and the heat dissipation effect is better.

Owner:HUNAN ELECTRICAL COLLEGE OF TECH

Lighting assembly

InactiveCN106855195AAvoid lifespanLow costLighting applicationsMechanical apparatusEngineeringMechanical engineering

The invention discloses a lighting assembly. A plurality of rotating wheels A are arranged on a lower horizontal section A, and the axes of the rotating wheels A are horizontal and perpendicular to a vertical section A; a driving rail includes a horizontal rack fixed on the side of a vertical section A, and the horizontal rack is located between an upper horizontal section A and the lower horizontal section A; a plurality of rotating wheels B are arranged on a lower horizontal section B; the driving rail and a supporting rail are oppositely arranged left and right, a gear is horizontally arranged between the driving rail and the supporting rail and supported by the rotating wheels A and the rotating wheels B together, and the gear is meshed with the horizontal rack; a motor is arranged above the gear, an output shaft of the motor is connected with the center of the gear, and the motor is fixed on the upper horizontal section A and can slide along the upper horizontal section A in the horizontal direction; the lamp is arranged on the lower surface of the gear. Only one lamp can achieve the transformation of illumination areas, the lighting assembly is low in cost and low in power consumption, the problem that the service life of the lamp is shortened due to frequent switching of the lamp is avoided, and the working noise of the lighting assembly is low.

Owner:潼南县铭辉灯具制造厂

Position-changing lamplight assembly

InactiveCN106855218AAvoid lifespanLow costLighting applicationsMechanical apparatusMechanical engineeringPower consumption

The invention discloses a position-changing lamplight assembly. The position-changing lamplight assembly comprises a horizontal gear rack fixed to the side face of a perpendicular section A, and the horizontal gear rack is located between an upper horizontal section A and a lower horizontal section A; a driving track and a supporting track are oppositely arranged on the left and right sides; a gear is horizontally arranged between the driving track and the supporting track, jointly supported by the lower horizontal section A and a lower horizontal section B, and engaged with the horizontal gear rack; a motor is arranged above the gear, an output shaft of the motor is in center connection with the gear, and the motor is fixed to the upper horizontal section A and can slide in the horizontal direction of the upper horizontal section A; a lamp is arranged on the lower surface of the gear; the position-changing lamplight assembly further comprises sucking discs arranged on the upper surface of the upper horizontal section A and the upper surface of an upper horizontal section B. The position-changing lamplight assembly is convenient to install, changing of illuminating regions can be achieved with only one lamp, in this way, cost is low, power consumption is low, and it is avoided that because the lamp is frequently turned on and off, the service life of the lamp is shortened.

Owner:潼南县铭辉灯具制造厂

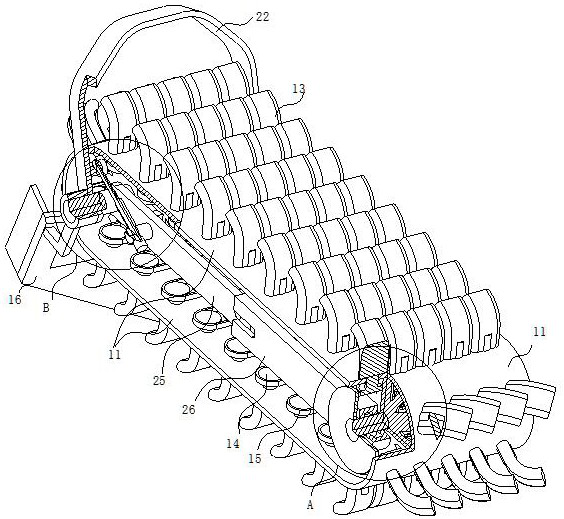

Ditching and soil loosening integrated equipment for land consolidation

ActiveCN114342583AReduce mechanical wearExtended service lifeSoil-working equipmentsPloughsLand consolidationAgricultural engineering

The invention discloses ditching and soil loosening integrated equipment for land consolidation in the technical field of land ditching, which comprises a rubber belt, a supporting mechanism for supporting the shape of the rubber belt is arranged on the inner side of the rubber belt, and a plurality of groups of digging mechanisms for digging soil and ditching are arranged on the side wall of the rubber belt at equal intervals; each group of earth cutting mechanism comprises a plurality of direction rods which are arranged in rows at equal intervals, the direction rods are perpendicular to the outer surface of the rubber belt and are rotationally arranged on the side wall of the rubber belt, a bent digging plate is fixedly arranged on the direction rod located on the outer side of the rubber belt, and a direction synchronizing wheel is coaxially and fixedly arranged at the end head of the direction rod located at the lower end of the rubber belt; according to the chain type ditching machine, the problems that according to an existing chain type ditching machine, a fixed scraping plate is generally adopted to rotate around a chain to dig out soil under the ground, the direction of the fixed scraping plate cannot be changed, when the fixed scraping plate moves to the upper end of the ground along with the chain, the soil digging side of the digging plate faces upwards, and the soil cannot be efficiently discharged are solved; and therefore, the problem that the ditching efficiency is low is solved.

Owner:程学田

Battery module and battery system comprising same

ActiveCN101894964BAvoid lifespanImprove thermal efficiencySecondary cellsHeat managementElectrical battery

The invention discloses a battery module and a battery system adopting the battery module, an electrode terminal is arranged on the end surface of a monomer battery, and a plurality of the monomer batteries are connected in series and / or in parallel through the electrode terminals, wherein the battery module further comprises a metal air duct, the metal air duct is in insulation, heat conduction and connection with the electrode terminals, and the metal air duct is used for reducing or increasing the temperature of the monomer batteries. A heat management structure adopted by the battery module and a heat management system of the battery system can effectively regulate the temperature in the battery module, avoid the inconsistencies in battery performances, and further avoid reducing the service life of the batteries or causing safety accidents.

Owner:BYD CO LTD

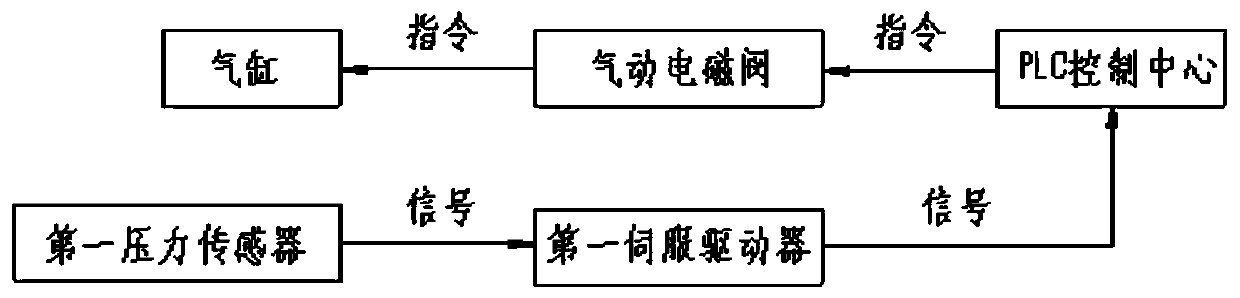

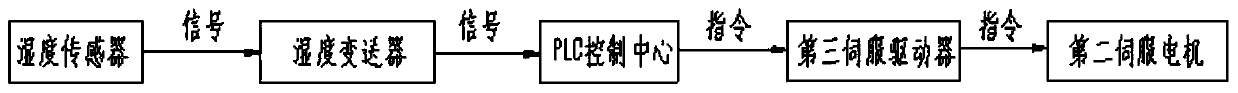

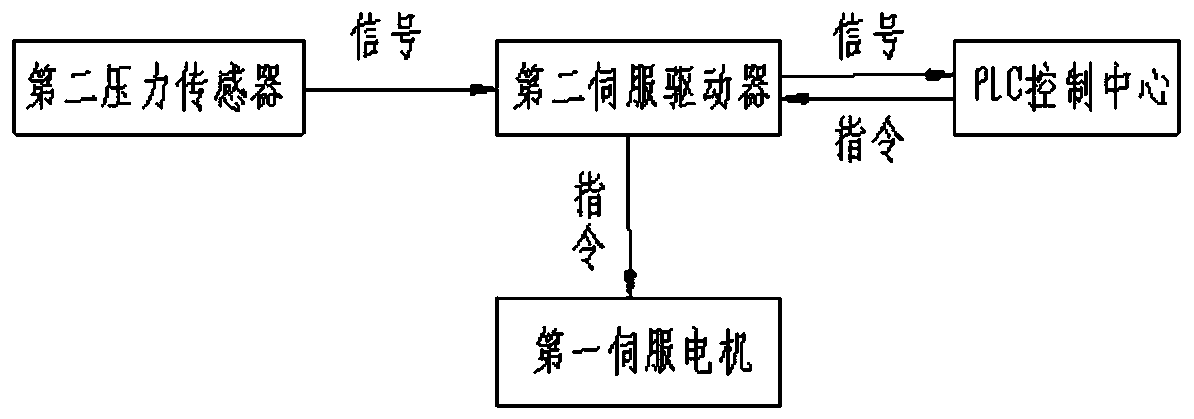

Intelligent system for controlling oil sludge pyrolysis carbonization

InactiveCN109870975AEasy to controlEasy to operateProgramme control in sequence/logic controllersControl engineeringCarbonization

The invention provides an intelligent system for controlling oil sludge pyrolysis carbonization. The intelligent system comprises a discharging control module, a conveying control module, a drying control module, a pyrolysis detection module and an intelligent control center, wherein the discharging control module is connected with the intelligent control center and is used for controlling the quantity of oil sludge in a feeding device; the conveying control module is connected with the intelligent control center, and is used for controlling a conveying device of the oil sludge; the drying control module is connected with the intelligent control center and is used for controlling a drying machine to work; and the intelligent control center is arranged in the intelligent system and is usedfor intelligently controlling the modules. The intelligent control center is used to control the modules, so that the intelligent control of the oil sludge pyrolysis carbonization system is realized;and therefore, the system has the characteristics of being easy to control and simple and stable in operation.

Owner:中科天龙(厦门)环保股份有限公司

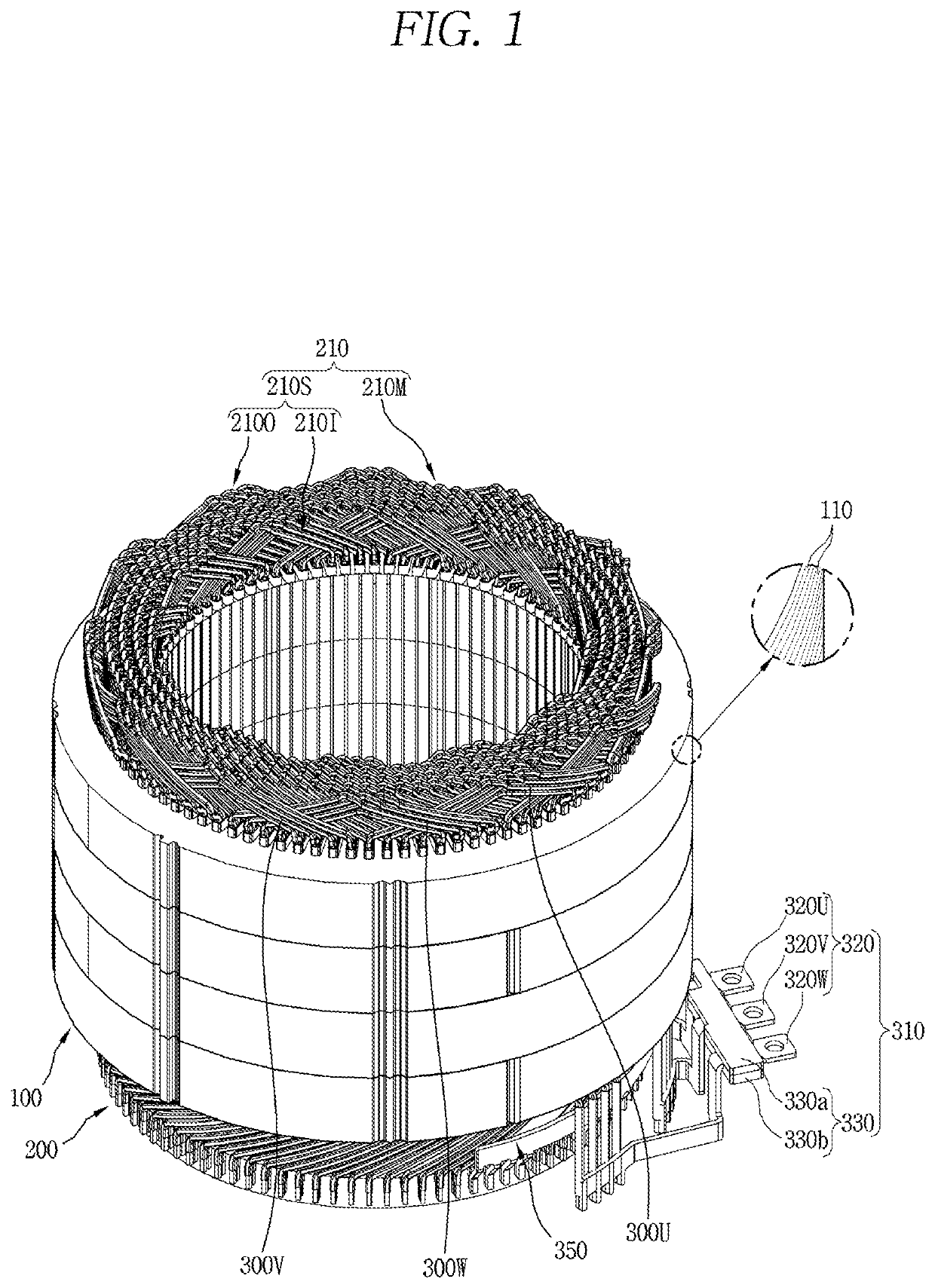

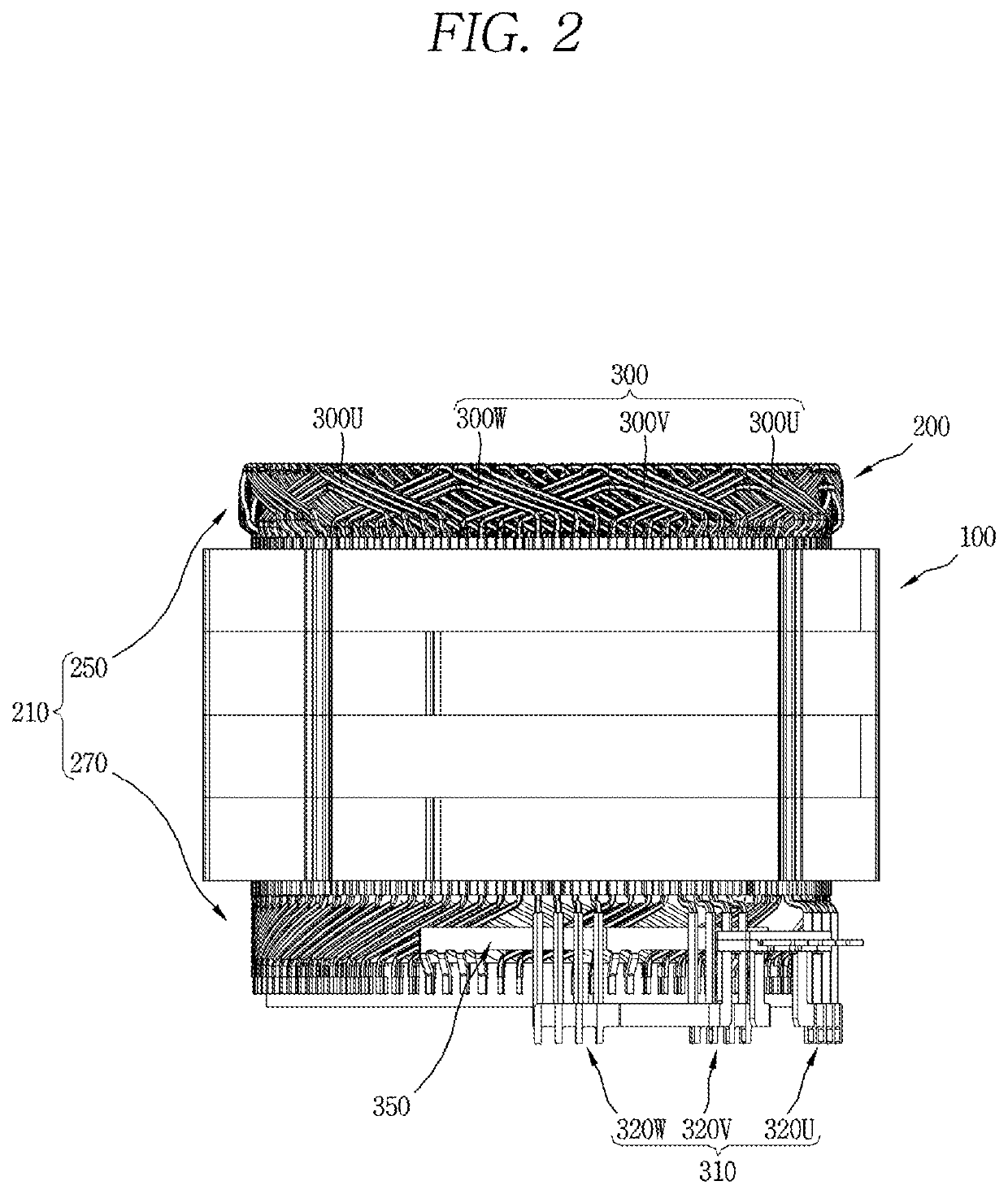

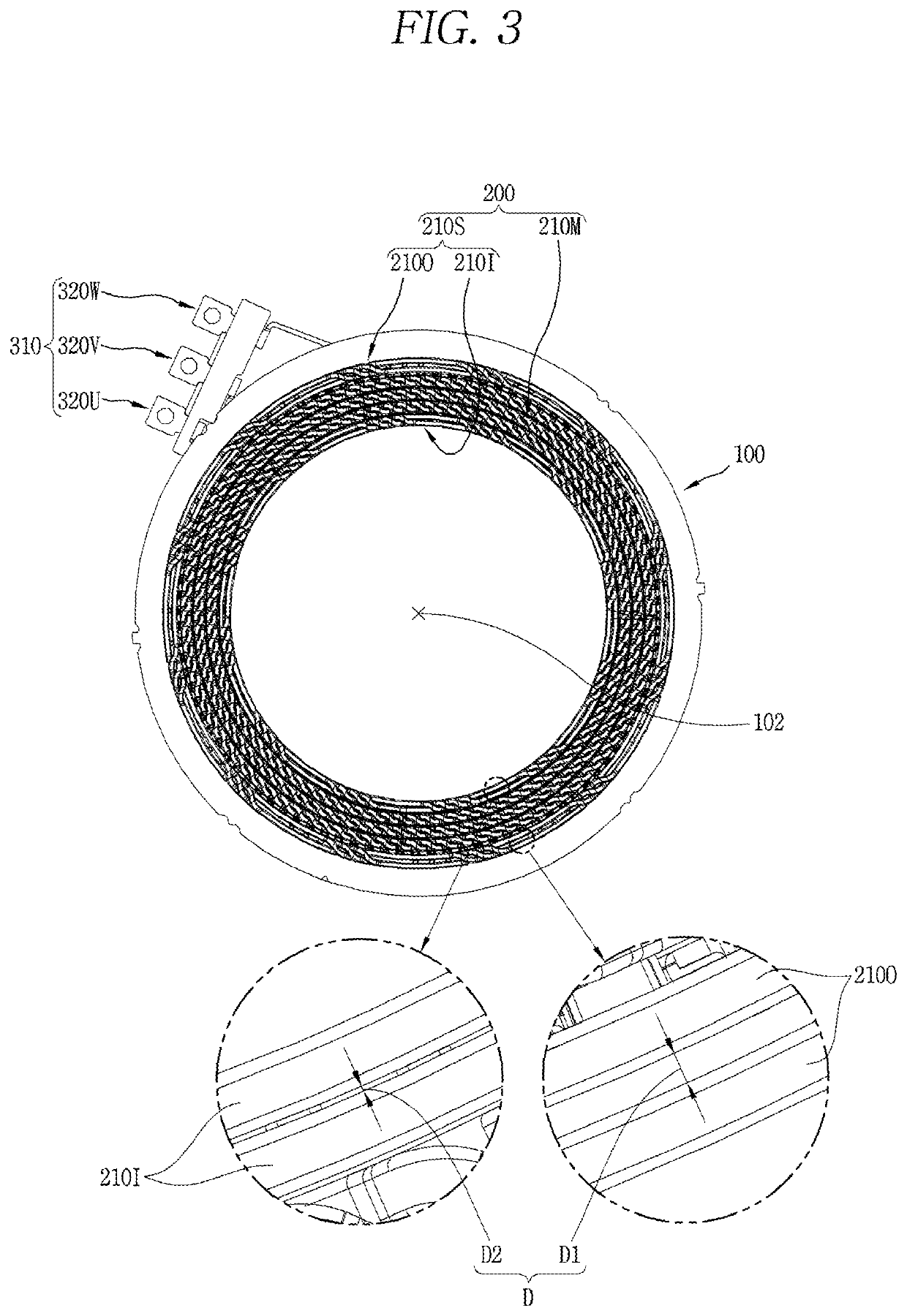

Stator for electric motor

PendingUS20220344993A1Avoid lifeSuppressing of dischargeMagnetic circuit stationary partsManufacturing dynamo-electric machinesLow voltageStator coil

A stator for an electric motor according to the present disclosure includes a stator core having a plurality of slots and teeth, and a stator coil wound via the plurality of slots, wherein the stator coil includes a plurality of hairpins inserted into the plurality of slots and connected in series with one another, wherein the plurality of hairpins is spaced apart from one another by a partial discharge suppression distance to suppress partial discharge between adjacent hairpins, wherein a partial discharge suppression distance between hairpins with a high voltage distribution ratio is farther than a partial discharge suppression distance between hairpins with a low voltage distribution ratio when power is applied to the stator coil. This may result in suppressing reduction of lifespan of the stator coil due to the partial discharge of the hairpins.

Owner:LG MAGNA E POWERTRAIN CO LTD

Track illumination device

InactiveCN106855194ALow costReduce power consumptionLighting applicationsMechanical apparatusInterference fitElectricity

The invention discloses a track lighting device, which includes a horizontal rack fixed on the side of a vertical section A; a driving track and a supporting track are arranged opposite to each other; Mesh with the horizontal rack; the motor is set above the gear, the output shaft of the motor is connected to the center of the gear, the motor is fixed on the upper horizontal section A, and the motor can slide in the horizontal direction along the upper horizontal section A; the center position of the lower surface of the gear A housing chamber is provided; it also includes a bearing with an interference fit between the outer surface and the inner surface of the housing chamber, and a fixing post with an interference fit with the inner surface of the bearing, on which the lamp is fixed; it also includes a sliding bearing arranged on the lower horizontal section A. rod, and a sliding ring arranged on the fixed post, and the sliding ring is sleeved on the sliding rod. The invention only needs one lamp to realize the transformation of the illumination area, has low cost, low power consumption and stable light.

Owner:潼南县铭辉灯具制造厂

Grounding system suitable for urban rail transit

ActiveCN111384710ASmall forward resistanceRestrict flowEmergency protective arrangements for limiting excess voltage/currentConnection contact member materialAutomatic controlElectrical connection

A grounding system suitable for urban rail transit is disclosed. The working grounding device is configured in that symmetrical working grounding points are arranged on the left side and the right side of a vehicle body, and each working grounding point is electrically connected with a switch, a carbon brush and a wheel set in sequence. The protective grounding device is configured in that symmetrical protective grounding points are arranged on the left side and the right side of a vehicle body, and each protective grounding point is electrically connected with a control switch, a power diode,a grounding carbon brush and a wheel set in sequence; and an automatic control system is used for regulating and controlling the currents of the two grounding devices, so that the currents on the twosteel rails are approximately equal. Power diodes are adopted for protection grounding, current is limited to only flow into the steel rails from a train body, damage of train rail backflow to train-mounted weak point equipment is avoided, the currents on the two steel rails are equal through an automatic control system, and the safety of a train is improved.

Owner:SOUTHWEST JIAOTONG UNIV

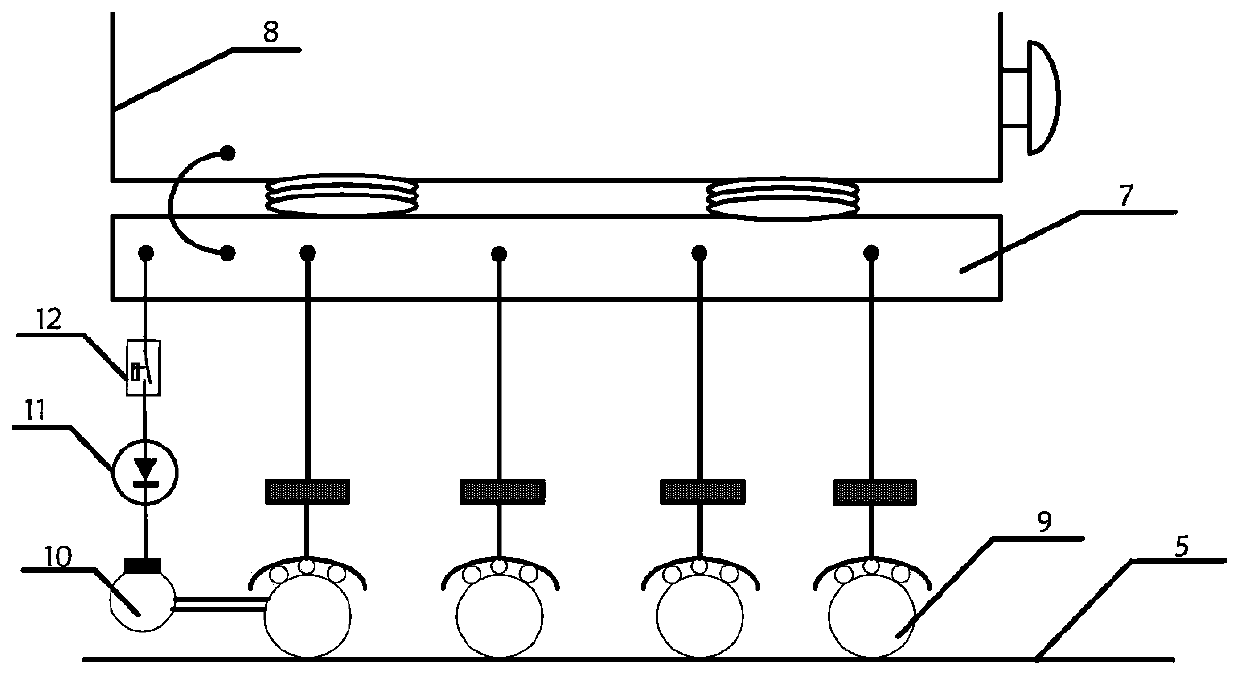

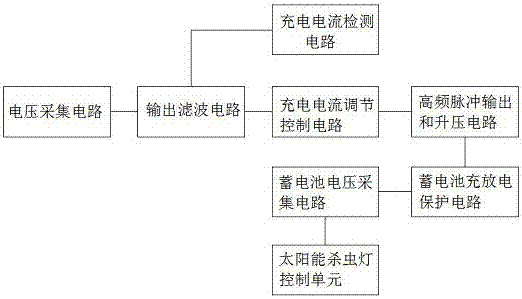

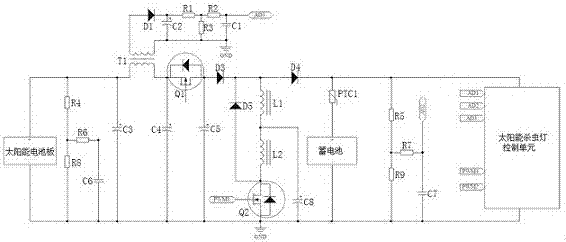

Charging circuit of solar beneficial protection lamp and charging method thereof

ActiveCN107370231AAvoid lifespanCrystallization mitigation and eliminationSecondary cells charging/dischargingElectric powerSolar cellConstant current

The invention relates to the technical field of solar insecticide, and especially relates to a charging circuit of a solar beneficial protection lamp and a charging method thereof. The charging circuit comprises a voltage acquisition circuit, an output filtering circuit, a charging current detection circuit, a charging current regulating control circuit, a high-frequency pulse output and boost circuit, a storage battery charging and discharging protection circuit, a storage battery voltage acquisition circuit, and a solar beneficial protection lamp control unit. Beneficial effects of the circuit are that through detecting voltage of the solar cell panel and voltage of the storage battery, the storage battery is charged in a boost method under the condition that voltage of the cell panel is relatively low, and multi-step constant current is used to prevent life reduction of the storage battery caused by charging, and high-frequency resonance pulse current reparative charging is used to relieve and eliminate crystalline phenomenon in the storage battery.

Owner:新乡市天意新能源科技开发有限公司

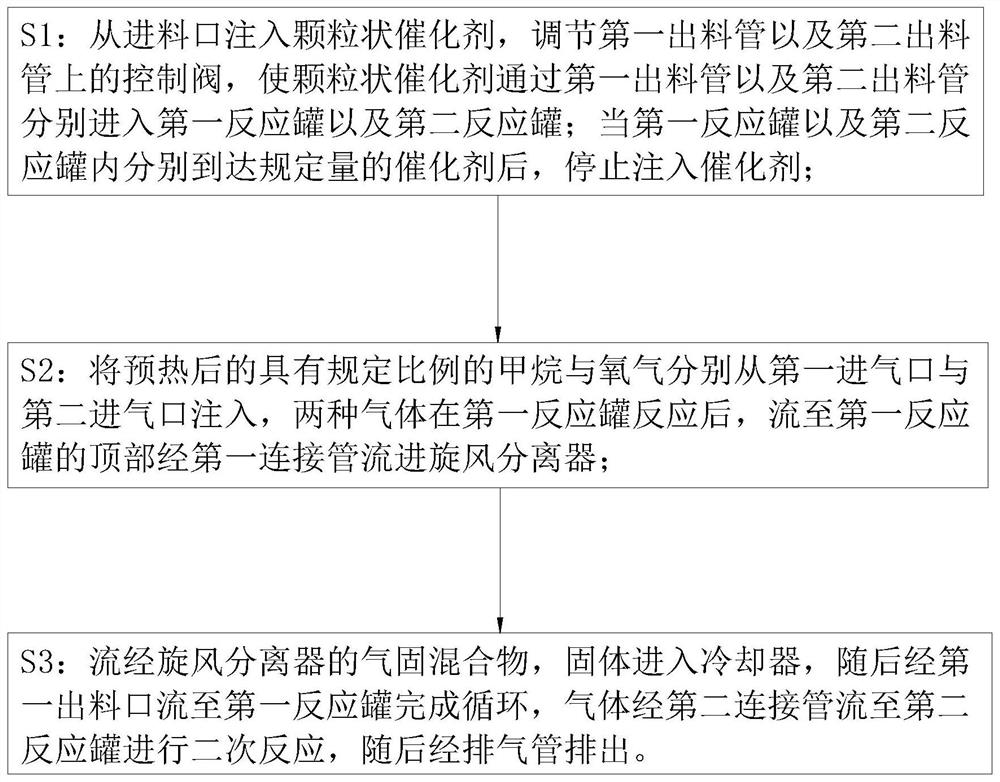

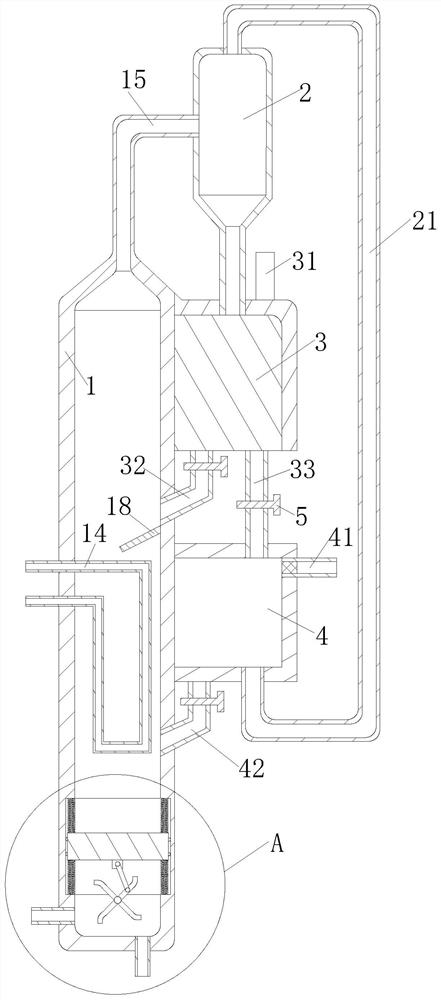

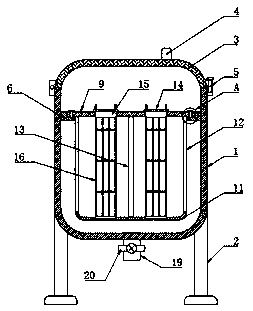

Reaction device and process for preparing ethylene through oxidative coupling of methane

PendingCN113976048AAvoid too thickAvoid duplicate joinsDispersed particle separationHydrocarbon by hydrocarbon condensationPtru catalystProcess engineering

The invention belongs to the technical field of ethylene preparation, and particularly relates to a reaction device and process for preparing ethylene through oxidative coupling of methane. The reaction device comprises a first reaction tank, a cyclone separator, a cooler and a second reaction tank. According to the invention, methane and oxygen are introduced from a first gas inlet and a second gas inlet respectively, mixed gas blows a catalyst to rise, a reaction is carried out in the process, the solid of a gas-solid mixture enters a cooler under the action of a cyclone separator and flows through a first reaction tank to complete circulation so as to prevent the catalyst from being accumulated too thick, recycle the catalyst and avoid repeated addition of the catalyst, the separated gas enters a second reaction tank for secondary reaction so as to make the reaction more sufficient, and then the gas is exhausted through an exhaust pipe.

Owner:杨凡

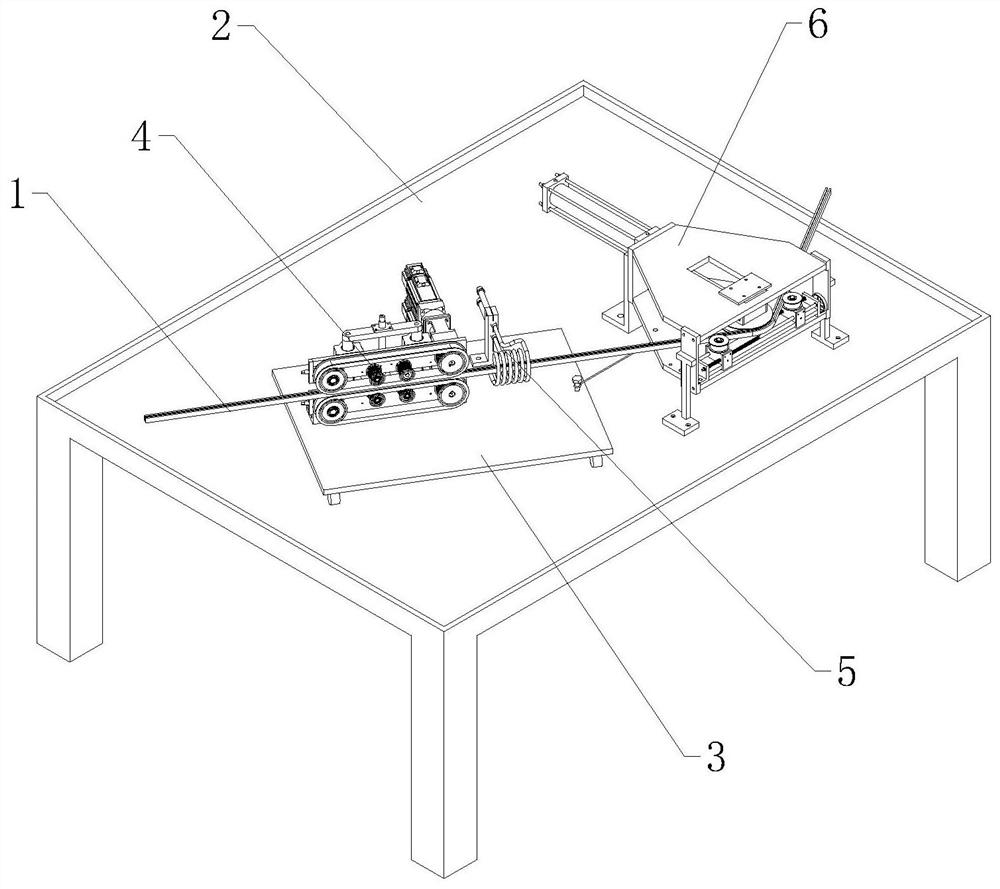

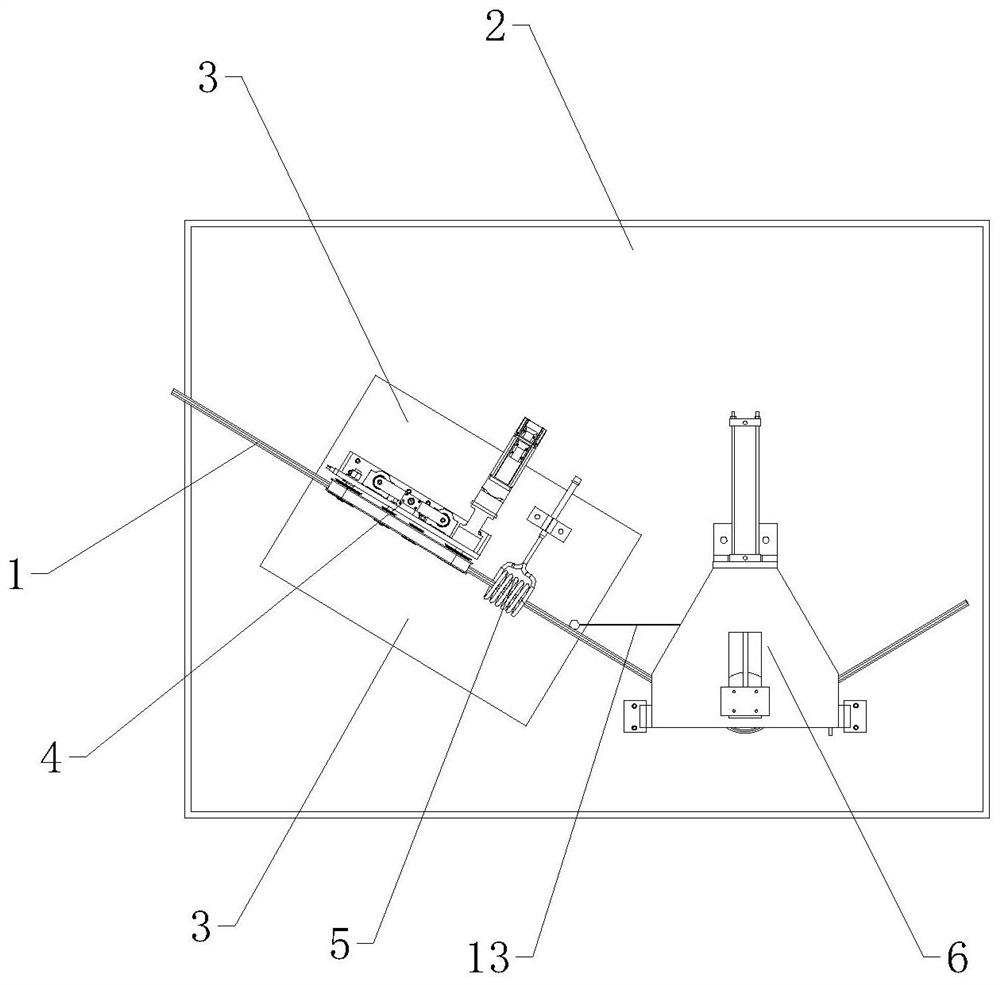

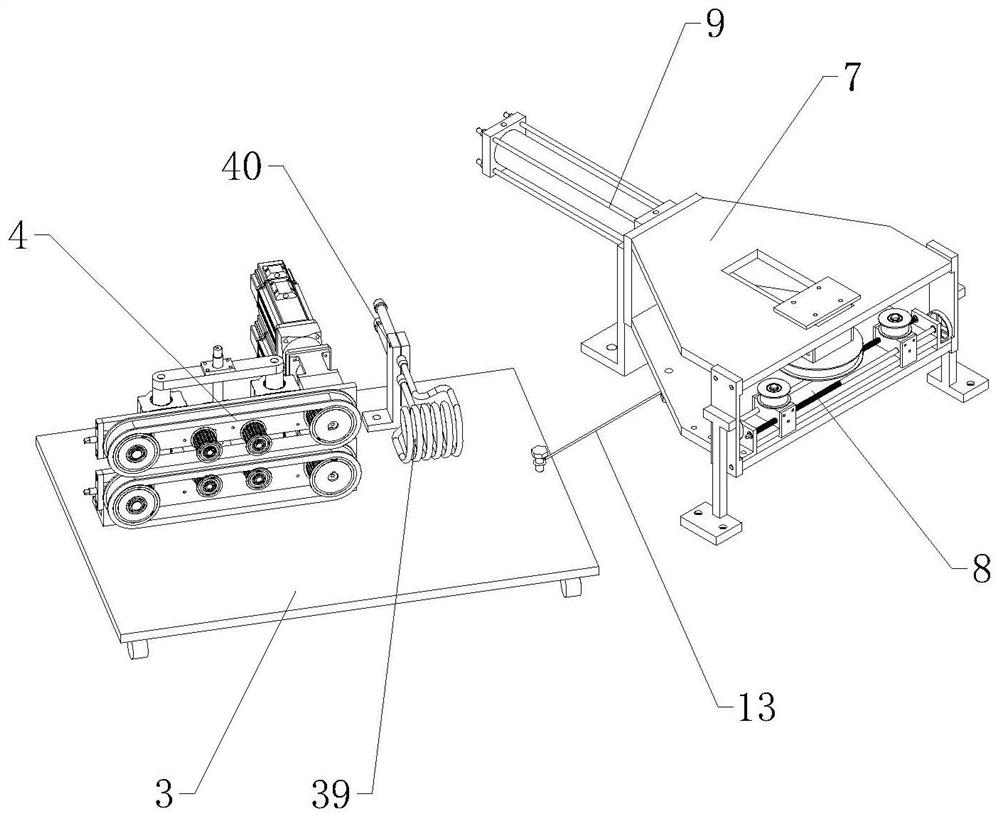

Microwave-heating anti-fatigue device for bending aluminum alloy guide rail

PendingCN112453135AAvoid lifespanAvoid damageMetal-working feeding devicesPositioning devicesEngineeringAlloy

The invention relates to the field of machining of metal guide rails, in particular to a microwave-heating anti-fatigue device for bending an aluminum alloy guide rail. The microwave-heating anti-fatigue device comprises a workbench, a moving carrier, an automatic feeding mechanism, an electromagnetic heating mechanism and a bending mechanism, wherein the moving carrier, the automatic feeding mechanism, the electromagnetic heating mechanism and the bending mechanism are arranged on the workbench; the bending mechanism comprises a supporting frame, a bidirectional adjusting and positioning mechanism and a pressing and bending mechanism; the bidirectional adjusting and positioning mechanism comprises two positioning wheels and one bidirectional moving mechanism which is used for driving thetwo positioning wheels to move oppositely; the pressing and bending mechanism comprises an air cylinder and a movable pulley; the air cylinder is fixedly arranged on the supporting frame; an output shaft of the air cylinder is connected with the movable pulley; and the movable carrier is connected with the bending mechanism through a pull rope. The microwave-heating anti-fatigue device provided bythe invention, a to-be-bent position of a guide rail is subjected to local electromagnetic heating so that material damages caused by metal fatigue in the bending process of the guide rail are reduced; and compared with a traditional manual or cold bending way, the microwave-heating anti-fatigue device can avoid the problem that the service life of the guide rail is remarkably shortened due to metal fatigue.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Lighting device

The invention discloses a lighting device. The lower horizontal section A is provided with a plurality of rotating wheels A, and also includes a horizontal rack fixed on the side of the vertical section A, and the horizontal rack is located between the upper horizontal section A and the lower horizontal section A. , the lower horizontal section B is provided with a plurality of runners B; the driving track and the supporting track are arranged opposite to each other; the gears are arranged horizontally, the gears are arranged between the driving track and the supporting track, and the gears are jointly supported by the runners A and B. The gear meshes with the horizontal rack; the motor is set above the gear, the output shaft of the motor is connected to the center of the gear, the motor is fixed on the upper horizontal section A, and the motor can slide in the horizontal direction along the upper horizontal section A; the lamp is set on the gear The lower surface; also includes a magnet A arranged in the lower horizontal section A and a magnet B arranged in the lower horizontal section B. The invention has stable operation and low noise, only needs one lamp to realize the transformation of the lighting area, and has low cost and low power consumption.

Owner:潼南县铭辉灯具制造厂

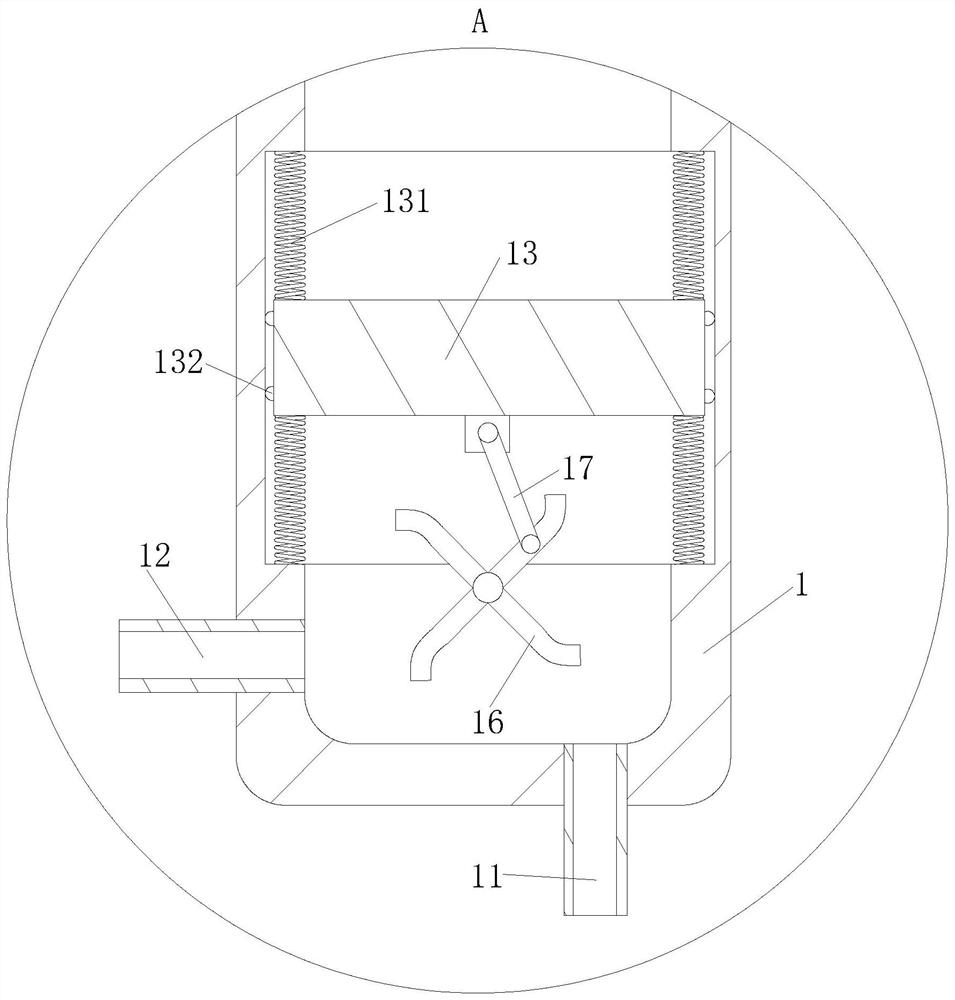

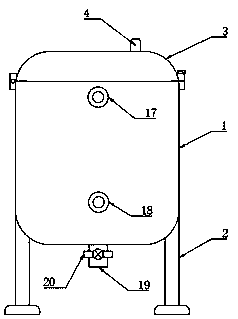

Water treatment equipment with conveniently replaceable filter bags

PendingCN109224568ANot easy to looseGuaranteed stabilityGravity filtersStationary filtering element filtersWater flowEngineering

The invention discloses water treatment equipment with conveniently replaceable filter bags. The water treatment equipment comprises a casing. The lower end of the casing is symmetrically welded withfour support columns; the lower end of each of the support columns is welded with a base; and the lower end of each of the bases is provided with a non-slip pattern. The upper end of the casing is provided with a sealing mechanism. A supporting mechanism is provided inside the casing. According to the invention, by means of the stabile support from the support mechanism, the stability of the filter mechanism during operation is ensured, the filtering effect is ensured, and the problem that the filter mechanism is swayed under the impact of the water flow and causing the life of the component to be shortened is avoided. All the second frame and the filter bag can be moved out of the casing at one time, so that a user can replace the filter bag externally. After the removal, the operation space becomes large, is convenient for the user to replace the filter bag, and also facilitates the user to clean the removed component.

Owner:湖州欧汇再生资源科技有限公司

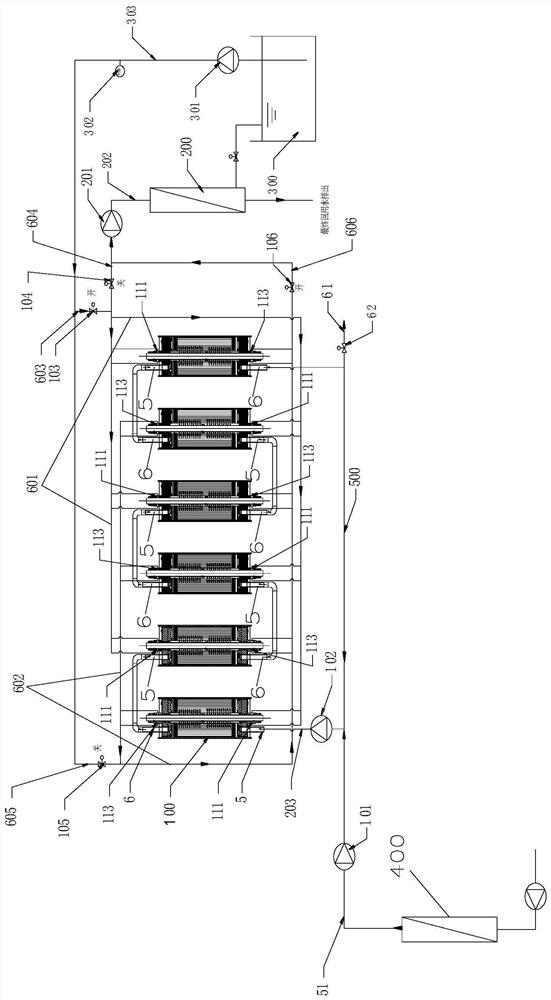

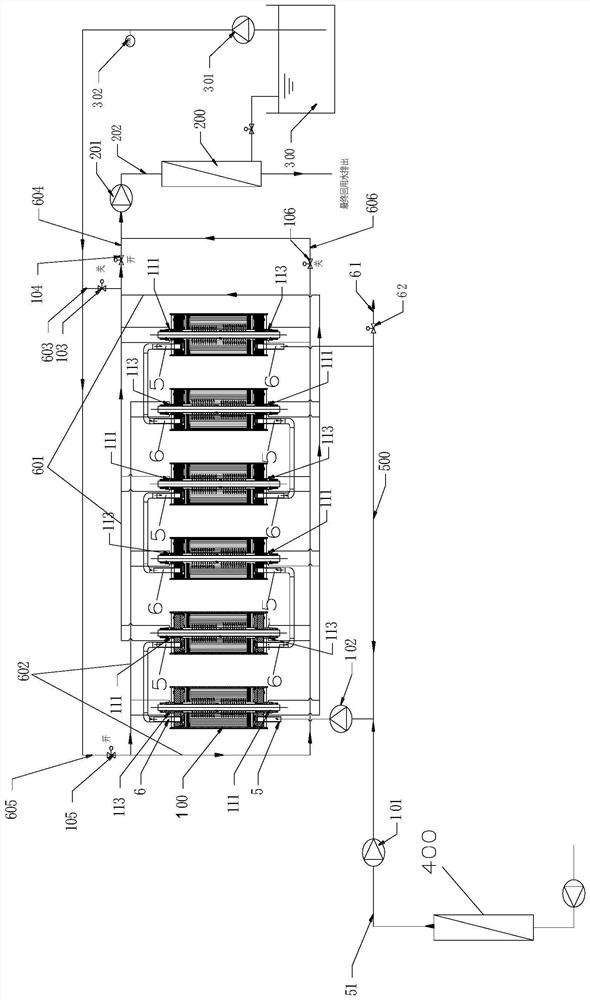

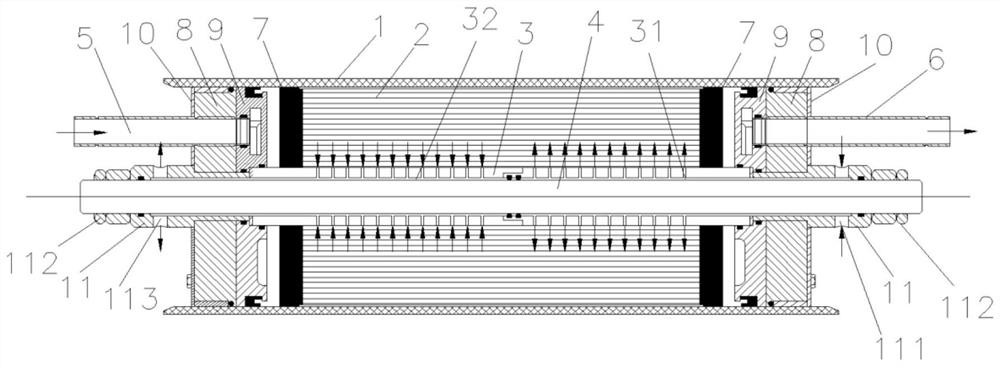

A kind of water treatment system and method

ActiveCN112142165BImprove antifouling performanceReduce concentration differenceSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisWater treatment systemWater production

The invention belongs to the field of water treatment. A water treatment system comprises a liquid inlet pipe to be treated, a concentrated liquid outlet pipe and at least one circulation assembly. A return pipeline is connected between the liquid inlet pipe to be treated and the concentrated liquid outlet pipe. The circulation assembly includes a liquid inlet pipe and a liquid outlet pipe communicated with the return line, a membrane module is arranged between the liquid inlet pipe and the liquid outlet pipe, and the inner cavity of the water production pipe of the membrane module includes a brine channel and a Mixed solution channel, the two ends of the water production pipe are respectively provided with a first port and a second port, one of the first port and the second port is used to inject brine into the brine channel, and the other is used to export the mixed solution in the mixed solution channel, water The treatment system also includes a switching mechanism, which is used to switch the liquid flow direction between the first port and the second port. The invention increases the flow rate of the liquid, and the positions of the brine channel and the mixed liquid channel are switched to each other, which improves the anti-fouling and clogging of the membrane module. performance.

Owner:JIANGSU KUNYI ENVIRONMENTAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com