Position-changing lamplight assembly

A lighting and component technology, which is applied to the parts of lighting devices, lighting devices, outdoor lighting, etc., can solve the problems of affecting the life of lamps, high power consumption, and high cost, so as to avoid the decline of lamp life, low power consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

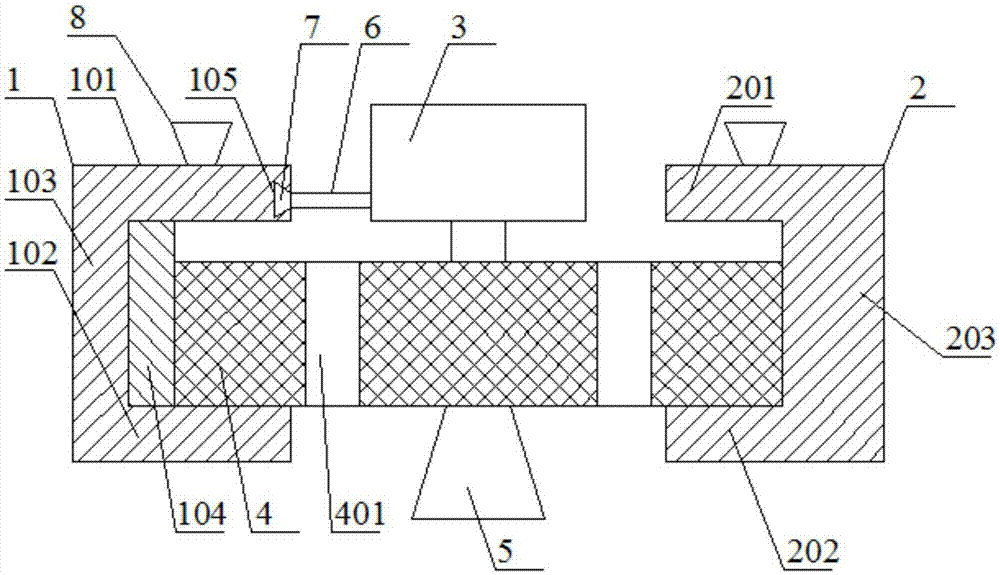

[0023] Such as figure 1 As shown, the displacement lighting assembly includes a driving track 1, a supporting track 2, a motor 3, a gear 4 and a lamp 5; the driving track 1 includes an upper horizontal section A101, a lower horizontal section A102 and a vertical section A103, and the upper horizontal section A101 is located at the lower Directly above the horizontal section A102, the upper and lower ends of the vertical section A103 are respectively connected to the ends of the upper horizontal section A101 and the lower horizontal section A102; the driving track 1 also includes a horizontal rack 104 fixed on the side of the vertical section A103, the horizontal rack 104 is located between the upper horizontal section A101 and the lower horizontal section A102; the support track 2 includes the upper horizontal section B201, the lower horizontal section B202 and the vertical section B203, the upper horizontal section B201 is located directly above the lower horizontal section B2...

Embodiment 2

[0027] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes a connecting bar 6, one end of the connecting bar 6 is connected to the motor 3, and the other end of the connecting bar 6 is provided with a dovetail protrusion 7; the upper horizontal section A101 is provided with a dovetail chute 105 on the side close to the motor 3 , and the dovetail protrusion 7 cooperates with the dovetail chute 105 .

[0028] The motor 3 is slidably fixed on the upper horizontal section A101 through the cooperation of the dovetail chute 105 and the dovetail protrusion 7, and the motor 3 does not rotate and can move with the gear 4 in the horizontal direction during the working process.

Embodiment 3

[0030] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the gear 4 is provided with a plurality of lightening holes 401 .

[0031] The gear 4 is provided with a plurality of lightening holes 401, which reduces the weight of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com